High performance separation system for fuel gas streams - Oil, Gas & Refineries - Gas

Fuel Gas Streams are frequently contaminated with liquid aerosols. The liquid exists as a stable and persistent “smoke” in the gas stream. The liquid contaminant can enter the gas stream through any one of a variety of events including – phase separation and condensation, compressor lube-oils from compression, chemical addition to pipelines (including corrosion inhibitors), and entrainment from overheads of contact towers.

-

Most popular related searches

Conventional Approaches to separating the liquid c...

Conventional Approaches to separating the liquid contamination have utilized either demister pads, or horizontal filter-separators. These devices have been approximately 20 – 40% effective at removing the liquid aerosols from the gas streams. The reason for this inefficiency is directly related to:

- Aerosol droplet size distribution

- Flow configuration in the separator

Conventional devices are ineffective because they are not able to capture the most penetrating aerosols, and are unable to effectively remove even those aerosols that they capture.

Pentair Porous Media technologies have been developed to address the inherent deficiencies of the conventional gas-liquid separators, making it possible, for the first time, to effectively remove liquid aerosols from gas streams. This presents the capability of providing effective separation from nano-levels to that approximating a demister pad.

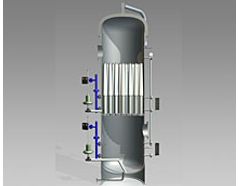

UltiSep - Aerosol Removal from Gas Streams

UltiSep sets a new standard in high-performance gas/liquid separation. UltiSep utilizes Pentair Porous Media’s proprietary microfiber media technology and patented APEX element design. These technologies are applied for high efficiency bulk liquid and aerosol removal from process streams. APEX technology affords the user an unprecedented ability to reduce liquid carryover and pressure drop while providing smaller footprints and lower capital costs. UltiSep housing configurations are designed via the use of Computational Fluid Dynamics (CFD) and other proprietary computer models that ensure accurate and complimentary design in conjunction with APEX. The implementation of these technologies offers the ideal business model for value added and optimized systems.

UltiSep offers the ability to maximize operational profitability by minimizing entrained liquids in process gas streams. Eliminating liquid and solid carry-over minimizes process upsets and the corresponding issues associated with them, such as; product loss, fluid make-up, off-spec products, contamination in feed streams entering processes, emulsions, foaming, fouling, corrosion and mechanical wear.

UltiSep allows the removal of liquids ranging from bulk fluids to entrained droplets as small as a viral particle, improving operational efficiency and profitability.

InterSep - Particulate Removal from Gas Streams

The InterSep high performance separation system is designed and manufactured to separate particulate contaminants from gas streams. With Pentair Porous Media's COMPAX coreless elements, which flow from the outside-to-the-inside, and is offered with an extended surface area media configuration utilizing our proprietary NexCel media. The media provides robust performance in glycol and aqueous service as well as hydrocarbon applications. COMPAX coreless element designs are currently being used by a large number of gas plants and hydrocarbon processes due to the superior operating economics and ergonomic advantages.