Power Generation Solutions for Refinery Gases Sector - Oil, Gas & Refineries

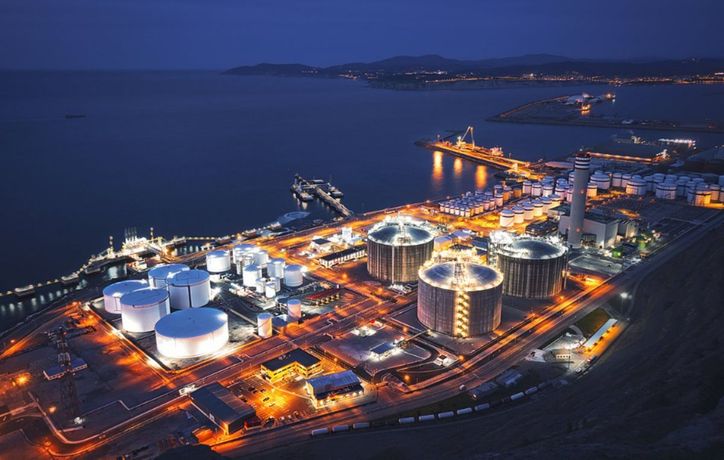

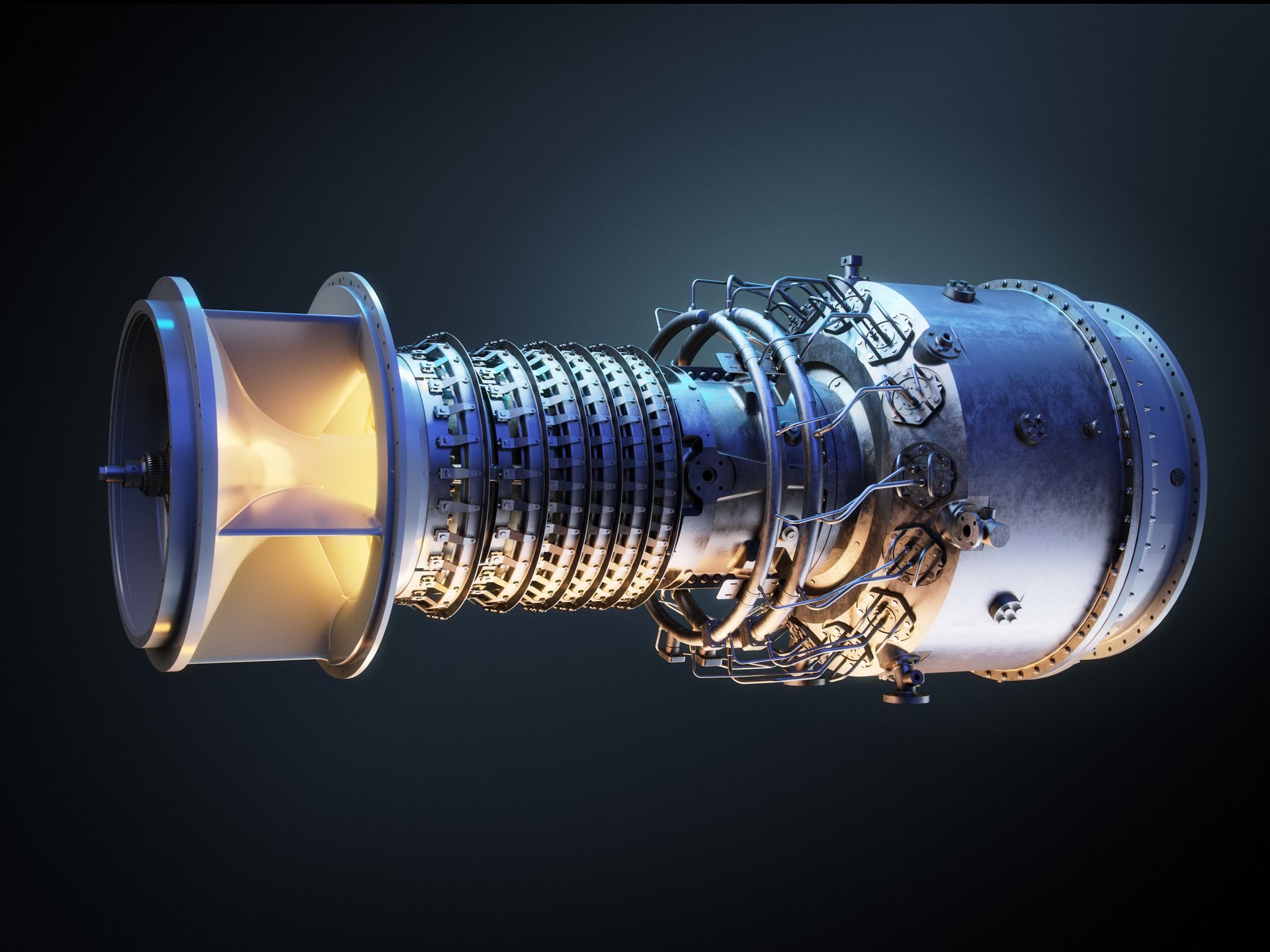

Solar Turbines’ modular, industrial gas turbines can integrate combined heat and power (CHP) allowing significant energy efficiency improvement. Refineries and petrochemical plants have the need to become integrated, energy efficient and sustainable. One benefit of the gas turbine solution is that streams can be used independently or blended together when the refinery production varies, and various gas producers/consumers come online or offline. This capability enables customers to reduce flaring and improve thermal efficiency while maximizing value in low emissions power and heat (CHP or CCGT configurations) compared to other solutions.

Overview Applications & Industries Served

Our capabilities are unique in the refinery market, and range from very low to high BTU gases, from high CO to high H2. Solar’s product portfolio utilizes process off gases from multiples of 9 MW to 50 MW fuel flow with LHV starting from 235 btu/Scf (2951 kJ/Nm3) in 3 MWe to 18 MWe. This allows quick deliveries and easy-to-install power/CHP units.

The biorefinery of the future will treat new feedstock, such as food waste, woody biomass and other biogenic feedstock, to produce biofuel and bio plastics. The increase of plastics’ recovery rates is bringing new feedstock to the refineries and petrochemical plants where it can be transformed by pyrolysis or gasification. The fuel flexibility of our gas turbines enables the use of various RFG, including syngas (from biomass or plastics gasification) that become available in the refinery. Solar’s equipment is also designed so that there is little to no impact on maintenance in order to keep businesses running.

Cogeneration Calculator

Use this cogeneration & Combined Heat and Power (CHP) calculator to quickly estimate your company's annual energy savings, along with the carbon emissions you will eliminate with our turbines.