Power Plant Coal Fired Boiler Filtration - Air and Climate - Air Pollution Treatment

Dust filter PPS Filter Bags For Coal Fired Boiler Gas Filtration.

-

Most popular related searches

Detailed Product Description

Detailed Product Description

PPS filter bag Ryton filter bag for coal fired boiler gas filtration

PPS filter bag Ryton filter bag for coal fired boiler gas filtration

Thermal power plant gas filter bags PPS dust filter bag high temprature resistant filter bag,coal fired boiler dust collector applied PPS filter bags

Specifications

- strictly sewing control

- Dust Collection Filter Bag

- PPS filter bag / PPS Filtration Bag / Dust Filter Bag / PPS filter bag

- Features Specifications: PPS Filter Bag.

Modification PPS Filter Bag Features:

1) Material:

Bag body ----- Modification PPS filter cloth

Bag cuff ----- steel-plate,rubber rings and garter spring is available

2) Working temperature:

Normal Working Temperature ----- 170-celsius-degree

Peak Working Temperature ----- 230-celsius-degree

3) Weight standard580g/m2

4) Filtration efficiencyup to 99.99%

5) Filtering precision: 120~200L/M2*S.

6) Dimension&Length: As customers' requirement.

7)Quality level: Fine strength & ideal air permeability&big durability.

Function of several dust filter bags

Filter bags, dust collector bags, dust bags, filte...

Filter bags, dust collector bags, dust bags, filter socks, bags, tubes, socks - they all mean the same thing: An industrial grade fabric filter made from heavy duty material, all textile based, used in dust collecting systems, in either process filtration or pollution control.

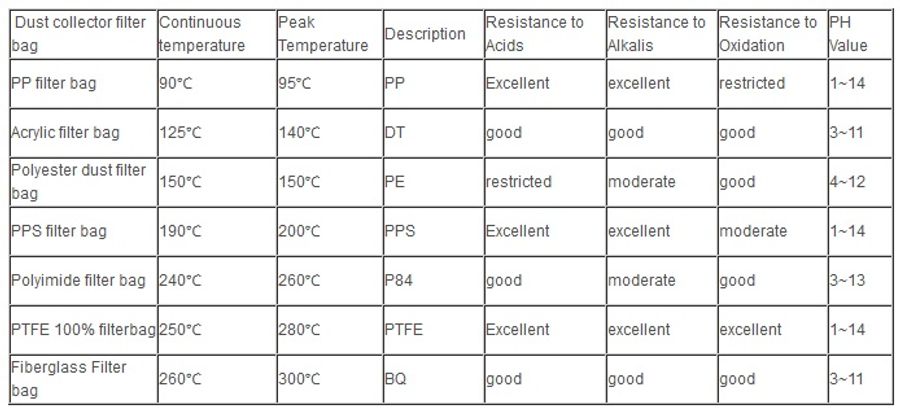

The main type of dust filter bags including Nomex filter bag ,PPS filter bags ,P84 filter bag ,PTFE filter bags ,Acrylic filter bags ,Polyester filter bags,dust filter bag ,bag filters,dust collector bags.

Dust bags come in 5 basic designs:

Pulse jet bags (bottom loader or bottom removal)

Pulse jet bags(top loader or top removal)

Shaker design

Reverse air design