Gas Cyclone Articles & Analysis

-

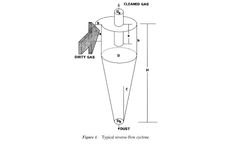

Impact of particle agglomeration in cyclones

The purpose of this work is to build a model to predict in a more realistic way the collection efficiency of gas cyclones, and in particular, of numerically optimized cyclones, that show very high collection efficiencies for sub-micrometer particles. These cyclones can be coupled to recirculation systems for further improving the collection efficiencies of these fine ...

-

Global Optimization of Reverse-Flow Gas Cyclones: Application to Small-Scale Cyclone Design

This paper addresses the optimum design of reverse-flow gas cyclones through the solution of 2 numerical nonlinear optimization problems that respectively maximize cyclone collection and an efficiency/cost ratio. The simulation model was based on the predictive properties of the 1998 finite diffusivity model of Mothes and Löffler, in which the particle turbulent dispersion coefficient is ...

-

Laboratory, pilot and industrial-scale validation of numerically optimized reverse-flow gas cyclones

This paper addresses the experimental validation of the optimum design of reverse-flow gas-cyclones, obtained through the solution of a numerical non-linear optimization problem, viz. maximizing cyclone collection. The simulation model is based on the predictive properties of a finite diffusivity model, where the particles' turbulent dispersion coefficient is estimated through an empirical ...

-

Why You Will Need A Continuous Tyre Pyrolysis Plant

Every time a pyrolysis plant is set up, they can be typically created to work nonstop. The workers in charge of maintaining them will work night and day. These are also known as continuous pyrolysis machines. Although you will have times where maintenance must be done, these are typically converting materials into charcoal and liquid fuel. If you have a considerable variety of tires in your ...

-

Why You Might Need A Continuous Tyre Pyrolysis Plant

When a pyrolysis plant is to establish, they are typically made to work nonstop. The workers in control of maintaining them can work night and day. These are typically also known as continuous pyrolysis machines. Although you will have times where maintenance should be done, they may be typically converting materials into charcoal and liquid fuel. If you have a significant number of tires on the ...

-

Energy Recovery System - Case Study

Addfield collaborated with an energy recovery company and one of the UK’s largest landscaping and recycling companies to produce the innovative idea of creating energy from waste. Some things cannot be recycled so instead of sending these to a landfill they are incinerated and reused to create hot water and electricity. This is then used to heat and power the garden centre whilst ...

-

WESPs: Securing a cleaner future for power-generating facilities - Case Study

This article explains why wet electrostatic precipitators remain a viable technology for dealing with today's increasingly stringent compliance issues. Despite recent, recession-related volatility in both power generation and consumption, industry analysts expect a resumption of long-term growth trends as continued global demand for energy — in both developed and developing nations ...

-

Information And Facts In Regards To The Wood Charcoal Making Machine

The wood charcoal making machine, also referred to as the biomass carbonization machine, is utilized to convert wood chips, tree barks, bamboo chips, tree branches, and agricultural waste into biomass charcoal via a process generally known as carbonization. This is actually the procedure of converting organic matter including plant materials and animal substances into carbon by heating it in the ...

-

Carbonization Machine: Uses And Benefits

Exactly What Is A Carbonization Machine? The biomass carbonization machine often known as the biomass charcoal machine or biomass pyrolysis plant uses a specialized waste-treatment technology that disposes of many types of different biomass waste. Samples of this waste include wood, wood chips, rice husk, plant matter, coconut shells, sewage sludge, palm shells, and much more. Carbonization ...

-

Advanced WESP designs assure superior gas cleaning performance

Nowadays, many industries are facing formidable environmental challenges and there is a growing need for effective, economical gas cleaning and air pollution control equipment. Michael Beltran of Beltran Technologies, Inc. reports on a renewed interest in high-efficiency wet electrostatic precipitators (WESPs) and discusses their importance for controlling sulphuric acid mists and other ...

-

Performance of the low-emission flare

Job report / Elbisgraben (Bale / Switzerland) The summer of 1992 had finally arrived. The 5MW low emission furnace in the district heating station Liestal was ignited, supplied with landfill gas from Elbisgraben landfill. Since then the plant has been running continuously and the comprehensive measurements taken, verify that all targets aimed at have been achieved: plant efficiency 90%, low ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you