Heat Exchanger Articles & Analysis

-

The benefits of heat regeneration in heat exchanger systems

Heat exchangers which employ heat recovery or regeneration should not be confused with ‘regenerative heat exchangers,’ which are a specific type of heat exchanger. What we mean by heat regeneration at HRS is the recovery of as much surplus heat (or cooling capacity) as possible after the primary function of the heat exchanger has been performed. This can then be reused to either ...

-

Heat Exchanger Package/Skid

Accessen GU series heat exchanger package is a complete set of district heating control equipment integrated with the plate heat exchanger, circulating pump, makeup pump, thermometer, pressure gauge, various sensors, piping, valves, and industrial controls. Electrophoresis coating provides a uniformed finish on the inside of the pipelines and welding seams which in turn also greatly improves the ...

-

The Engineering Behind Shell and Tube Heat Exchangers and Their Benefits

Shell and tube heat exchangers are used for the flow of in-line heating and cooling. The innovative design allows the movement of fluids through the tubes and exterior shell delivering changeability. The movement of fluid can be run in a counterflow, cross flow, or parallel mode. The flow of the fluids can not be reversed, so the development of dirty pockets is then eliminated during the ...

By Fluorostore

-

Air Products Opens LNG Equipment Test Facility, Expands LNG Manufacturing Plant

Air Products, the world’s leader in LNG technology and equipment, recently held a dual celebration event at its Port Manatee, Florida LNG Manufacturing Facility. Participants took part in the ribbon-cutting for a new LNG equipment test facility (ETF) and a groundbreaking for a facility manufacturing expansion project at the site. The location of the ETF at the Port Manatee ...

-

Choosing the right heat exchanger for wastewater applications

Heat exchangers are crucial to many processes in the water industry, in aerobic or anaerobic digestion plant, for cooling or evaporation, and for sludge concentration. Choosing the right heat exchanger can appear daunting, and maximising productivity is ...

-

Multiple uses for heat exchangers in brewing

There are numerous uses for heat exchangers in breweries, from cooling, pasteurising and fermenting products, through to efficiently dealing with waste streams such as yeast slurry. Compared to other methods of heating, heat exchangers can be much more energy efficient, providing both environmental and economic benefits. One of the first uses of heat exchangers in brewing is for rapidly cooling ...

-

Performance optimisation of the combined single flash binary geothermal power plant

In this paper, the optimal operating conditions of a hypothetical combined single flash-binary geothermal power plant are investigated and performance analyses are performed based on Aydin-Germencik field in Turkey. The relationship between flashing pressure, turbine inlet pressure of the binary cycle and total heat transfer area of the heat exchanger are determined for maximum power output of ...

-

The Major Components of Heat Exchangers

Heat exchangers are not only one of the most common pieces of equipment found on industrial sites, they are also one of the most important. Despite the name, heat exchangers are used for both heating and cooling and are actually used more often for cooling, especially on industrial sites such as refineries or processing plants. These pieces of equipment are not “one size fits all.” In ...

-

Thermal analysis of smart fins in a micro heat exchanger

Micro heat exchangers using smart fins undergo variation of temperature along the passage of fluid flow. This requires analysis of these smart cantilevers under thermal load. In the present research, thermal analysis of bi-metallic smart, surface mounted, piezo patched cantilevers under thermal excitation, has been carried out. Electro-thermo-elastic governing equations and constitutive equations ...

-

Choosing the Right Heat Exchanger for Food Processing

All but the most basic heat exchangers are created to a bespoke brief, designed to take into account the material/s being heated or cooled, the heating or cooling medium, the amount of product being processed, product velocity, risk of fouling and a host of other factors. However, over the years some standard design types have emerged (as well as more specific types) and understanding the ...

-

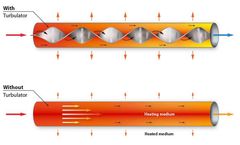

The value of increasing the efficiency of tubular heat exchangers by using turbulators

Introduction Heat transfer enhancement in all types of heat exchanger systems is of great significance for the cooling and heating industry. In addition to saving energy, it also leads to a reduction in size and weight of equipment. In the last decade energy efficiency has become an increasingly important theme among policy makers as it can enable economic growth, reduce emissions and improve ...

-

What Are the Characteristics of Stainless Steel Corrugated Plate?

Stainless steel corrugated plates have several key characteristics, including: 1. Efficient Heat Transfer: The thin, corrugated stainless steel plates used in the design of heat exchangers provide efficient heat transfer with an extremely small footprint, making them ideal for demanding installations where space is at a premium. 2. High Pressure and Temperature Resistance: The brazed plate heat ...

-

Applying Analytics in the Denver Colorado Xcel Energy District Energy System - Case Study

Overview Xcel Energy owns and operates a district energy system in downtown Denver offering steam heating and chilled water cooling to a variety of large customers. To improve the operation and management of this system, Xcel Energy has deployed analytics software using near real time data from the entire system including steam heat exchangers, chilled water heat exchangers, and five central ...

-

9 Questions to Ask Your Heat Exchanger Supplier

Heat exchangers are commonly used for a wide range of purposes in the anaerobic and biogas sector, from digester heating and pasteurisation to evaporation, biogas dehumidification and exhaust gas heat recovery. With a wide range of types and designs available from numerous manufacturers, choosing the right solution, from the right supplier, can seem daunting. However, posing the right questions ...

-

Exergoeconomic analysis of an olive oil refining plant

This study deals with evaluating the performance of an olive oil refinery plant installed in Izmir, Turkey, using Exergy, Cost, Energy and Mass (EXCEM) method, which is based on the real operational data and costs of the equipments. The most efficient equipment is obtained to be the shell and tube type heat exchanger with an exergy efficiency value of 85.8% at 25°C, ranging from 86.2% to 85% for ...

-

HRS helps AD plant tap into additional heat from existing CHP

Operators of anaerobic digestion (AD) plants know how important it is to optimise energy use across all stages of the process. That is why many recapture as much heat as possible for reuse elsewhere, including from the hot exhaust gases generated by the combined heat and power (CHP) engines which turn the biogas from the AD plant into useful heat and electricity. Heat exchangers used for exhaust ...

-

Experimental investigation of flow-induced vibration in PFBR steam generator sector model

The 500 MWe Prototype Fast Breeder Reactor (PFBR) is under construction at Kalpakkam. It is a liquid metal sodium-cooled pool-type fast reactor with all primary components located inside a sodium pool. Fission heat is transferred to a secondary sodium system in an intermediate heat exchanger, which is in turn transferred to water in a Steam Generator (SG). The PFBR-SG is a vertical shell and ...

-

Thermo–economic analysis of heat pipe heat exchanger for waste heat recovery in thermal systems

Thermo–economic analysis of Heat Pipe Heat Exchanger (HPHE) for waste heat recovery in thermal systems using the P1–P2 and NTU methods is presented. The optimum effectiveness of a HPHE is given as a polynomial equation, whereas the net savings and payback period are given in closed form to enable the HPHE designer to determine the optimised values directly. In addition to this, exergy analysis of ...

-

A solar thermal power system in the city of Thessalonica with the use of the Pinch method for entropy minimisation

The objective of this paper is to create a small power plant, (producing 2 MW annually), which will be using solar energy as a driving fuel. The system is made up of three sub-systems: a set of Solar Collectors (SCS), a Rankine power cycle and a Heat Exchanger Network (HEN). Two cases with variations in the operation of the solar collectors and the heat exchanger network will be examined. The ...

-

Energy sustainable development through energy efficient heating devices and buildings

Energy devices and buildings are sustainable if, when they operate, they use sustainable (renewable and refuse) energy and generate nega-energy. This paper covers three research examples of this type of sustainability: (1) use of air-to-earth heat exchangers, (2) computer control of heating and cooling of the building (via heat pumps and heat-recovery devices), and (3) design control of energy ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you