Waste-to-Energy Solution for a Pharmaceutical Company

- Project: Sandoz Industrial Products S.p.A. - Novartis Group

- Location: Rovereto (TN), Italia

- Capacity: 768 m3/day

- Solution: Anaerobic Digestion plant and Biogas desulphurizer

Background

Sandoz, the generic pharmaceuticals division of Novartis, has a history spanning more than 120 years and is a worldwide, trusted leader in generics. Its strategic and customer-focused approach to develop, produce, and market high-quality, affordable medicines has turned Sandoz into one of the largest and most respected generic pharmaceutical companies worldwide. Their medicines are already available to 90 percent of people across the world and they are committed to further increase global access to affordable healthcare

................................................................................................................................................................................................................................................

Challenges

Sandoz S.p.A had an aerobic treatment plant for its wastewater, but the energy consumption and surplus sludge production were very high. Because the company wanted to make its operations more sustainable, a new anaerobic pretreatment was installed before the existing treatment plant.

The main challenge was to build and start-up the plant without interfering with the daily company production. Moreover, space for the new installation was very restricted, so the design required customized and detailed planning.

................................................................................................................................................................................................................................................

Solution

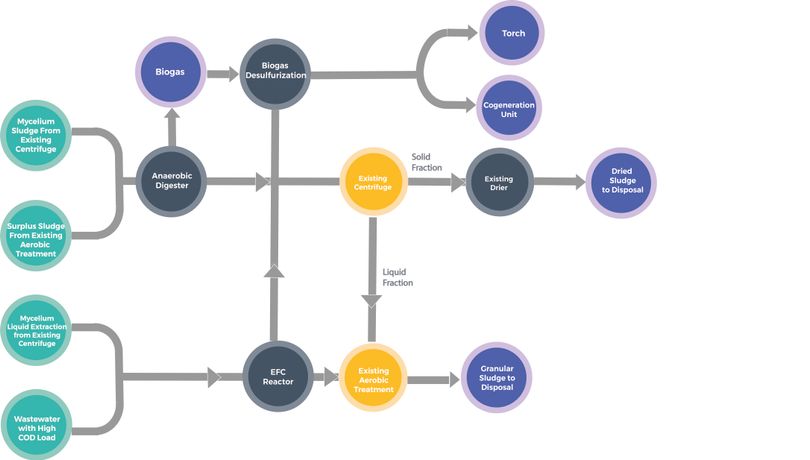

In order to meet the unique needs of Sandoz, Fluence Italy proposed a mixed anaerobic treatment through an anaerobic digester and a rapid anaerobic reactor, generating biogas through a cogeneration system. The External Forced Circulation (EFC) reactor is a technology completely developed and engineered by Fluence and meets the need for high efficiency and cost-effectiveness.

The plant ensued from six months of pilot tests performed directly at Fluence Italy facility. These activities allowed Fluence to find the best solution for Sandoz’s economic, structural, and operational requirements.

................................................................................................................................................................................................................................................

System Description

- Effluents: industrial wastes and wastewater from pharmaceutical industry

- Capacity: 768 m3/day

- Pre-treatment with classic anaerobic digester and EFC reactor

- Biogas desulphurizer

- Cogeneration unit and torch

Project Data

Capacity: 768 m3/d

Methane Production 2,920 m3/d

Electrical Energy Production:10,900 kWh/d

Thermal Energy Production: 12,600 kWh/d

Customer comments

No comments were found for Waste-to-Energy Solution for a Pharmaceutical Company. Be the first to comment!