Alternative Fuels Articles & Analysis

-

Why did a cement company deploy more than a dozen RDF alternative fuel preparation projects?

The cement industry is currently mired in multiple difficulties and is struggling. On the one hand, as the popularity of infrastructure construction recedes and the real estate market continues to cool down, a large number of excess cement products are backlogged in warehouses. Market competition has become increasingly fierce, prices have been continuously depressed, corporate profit margins ...

-

An RDF Alternative Fuel Preparation System For A Cement Company in Sichuan Province is on stable operation!

In October 2024, A cement company in Sichuan province adopted a Harden RDF alternative preparation system with advanced and multiple solid waste processing technologies, to achieve the continuous and steady operation of RDF alternative fuels processing for cement kiln. As a traditional high energy-consuming industry, the cement industry’s fuel and power costs have accounted for more than ...

-

The Role of Thermal Efficiency in Pyrolysis Reactor Performance

The thermal efficiency of a pyrolysis reactor is a critical factor in determining the overall performance, energy consumption, and economic feasibility of the pyrolysis process. Pyrolysis, a thermochemical decomposition process, is used to convert organic materials such as plastics, rubber, and biomass into valuable products like oil, gas, and charcoal. The efficiency with which the reactor ...

-

An RDF Alternative Fuel Preparation Project in Anhui, China is Successfully Put Into Operation!

In mid-October 2024, at the site of a ceramics factory with convenient transportation in Anhui Province, China, an RDF alternative fuel production line with an annual capacity of approximately 100,000 tons was successfully put into operation. It is a “green factory” for recycling local solid waste and is also the first Harden RDF alternative fuel preparation system in the region ...

-

Cement companies with RDF alternative fuel preparation system will seize the opportunity!

Mainstream carbon reduction methods In the cement clinker production process, industrial process emissions account for about 60%-65%, mainly carbon dioxide emissions produced by the decomposition of carbonates. Emissions from energy activities account for about 35%-40%, mainly carbon dioxide emissions produced during the combustion of fossil fuels such as coal. And the indirect ...

-

Alternative Fuel Production Solutions: Plastic Pyrolysis

The pursuit of sustainable energy sources has intensified as the world grapples with the dual challenges of waste management and energy security. Plastic pyrolysis, a method of converting plastic waste into valuable fuels, has emerged as a significant alternative fuel production solution. This process addresses both environmental and energy concerns by transforming plastic waste into usable ...

-

Is the charcoal making business profitable?

The charcoal making industry has experienced a renaissance in recent years due to increased environmental awareness and the pursuit of sustainable energy solutions. Carbonization equipment converts biomass waste into high-quality charcoal through pyrolysis, providing investor with a way to leverage green business models while meeting global demand for alternative fuel sources.With the ...

-

Plastic Pyrolysis to Oil: A Sustainable Solution for Raw Materials in New Plastic Production

Plastic pyrolysis to oil represents a sophisticated chemical process wherein plastic waste is subjected to high temperatures in the absence of oxygen, leading to thermal decomposition. Through this intricate procedure, various types of plastics are broken down into their constituent components, predominantly yielding liquid hydrocarbons known as pyrolysis oil. This pyrolysis oil, a versatile ...

-

The Hidden Threats of Plastic Incineration

In the realm of waste management, plastic incineration has emerged as a controversial practice fraught with environmental and health hazards. Despite being touted as a solution to reducing landfill waste and generating energy, the process of burning plastics poses significant risks to both human health and the environment. This comprehensive analysis delves into the perils associated with plastic ...

-

Oil Sludge Pyrolysis Technology: Realizing Energy Regeneration

Oil sludge pyrolysis technology stands at the forefront of sustainable waste management solutions, offering a promising avenue for energy regeneration and environmental conservation. This innovative process harnesses the power of pyrolysis to convert oil sludge, a hazardous byproduct of oil refining and drilling operations, into valuable resources. Understanding Oil Sludge Pyrolysis Oil sludge ...

-

Waste-to-Energy Excellence: Landfill Gas Power Plant in Greece - Case Study

HELECTOR, a subsidiary of ELLAKTOR Group, is an expert in the waste management and green energy production sector in South Eastern Europe. To further their commitment to alternative fuel production and biomass exploitation, HELECTOR selected Clarke Energy Hellas to supply and install a 3.52MW landfill gas power plant in Thessaloniki, ...

-

Ways To Obtain A Coconut Shell Biomass Pyrolysis Plant On The Market

The creation of coconuts is straightforward by nature. These are harvested, processed, and sold. Sometimes, the coconut shells are removed entirely. In these cases, these shells are then discarded. The natural process of decomposition will certainly occur. These can also be processed through burning or burying them. You will discover a way, however, to help make this process better yet. It is ...

-

Mini Pyrolysis Machine: Eco-Friendly Waste Solution

Welcome to our article on the Mini Pyrolysis Machine, an innovative and eco-friendly solution for waste management. This compact device is revolutionizing the way we address waste and transforming it into valuable energy. With its advanced pyrolysis technology, the Mini Pyrolysis Machine offers numerous benefits, from reducing landfill waste to generating income from recyclable materials. By ...

-

Versatility of Byproducts from a Plastic Pyrolysis Plant for Diverse Industrial Applications

At the heart of a plastic pyrolysis plant lies the process of pyrolysis, wherein plastic waste is subjected to high temperatures in the absence of oxygen, leading to the breakdown of complex hydrocarbons into simpler compounds. This thermochemical transformation yields a trifecta of valuable byproducts: pyrolysis oil, syngas, and carbon black. Pyrolysis oil, often referred to as bio-oil or ...

-

Investment Prospects of Coconut Shell Charcoal Making Machine in Indonesia

Indonesia, known for its abundant coconut resources, presents a lucrative opportunity for investment in the coconut shell charcoal making machine industry. With the rising demand for sustainable energy solutions and the versatility of coconut shell charcoal, investing in this sector holds promising prospects. This article explores the investment potential, market dynamics, and factors influencing ...

-

Potential of Pyrolysis Oil as an Industrial Alternative Fuel

In the realm of sustainable energy solutions, the utilization of pyrolysis oil as an industrial alternative fuel has emerged as a promising frontier, marking a paradigm shift in the pursuit of cleaner and more efficient energy sources. The symbiosis between technological advancements and environmental conscientiousness has propelled pyrolysis oil into the spotlight, positioning it as a key player ...

-

How to Dispose of End-of-Life Commercial Tires in the Transportation Industry: Pyrolysis

Introduction The transportation industry faces a pressing environmental challenge with the disposal of end-of-life commercial tires. This article explores the innovative solution of pyrolysis as a method to address this issue. Understanding the environmental impact of traditional disposal methods and the significance of adopting sustainable practices sets the stage for a comprehensive examination ...

-

Cost Reduction Battle! Another Cement Factory SRF Alternative Fuel Processing Center Has Been Put Into Operation!

In 2023, there are many projects for SRF alternative fuel processing of cement factories. The reason is that as the cement industry market continues to decline, cement companies have launched a "price reduction promotion" war. How to improve the comprehensive competitiveness of products and open source? How to save production costs and reduce expenditures? It has become the key to the ...

-

Good News: Biomass SRF Alternative Fuel Processing Systems Project Has Started

In recent years, the cement industry market has been sluggish, and many cement companies are facing greater cost pressure. At the same time, under the requirements of dual carbon goals and green development, they’re about to be included in the carbon trading system and reduce the use of fossil energy. A large domestic cement company has taken precautions and focused its attention on ...

-

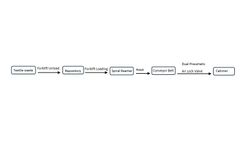

The Real Fact: High-quality SRF Alternative Fuel Should Look Like This!

In 2023, with the release of policies to reduce carbon emissions and energy consumption, and the price of coal continues to remain high, many cement companies have begun to lay out the "RDF/SRF alternative fuel" market. One cement company in Guangdong province has set up a simple waste textile SRF alternative fuel transportation and feeding system (as shown in the picture) The waste SRF is fed ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you