Biorefineries Equipment & Supplies

-

based in USA

The hydrolysis unit, an Andritz based system, can process up to 10 tons per day of chipped cellulosic biomass* into separate C5 and C6 sugar streams. The hydrolysis unit can operate using steam explosion, dilute acid/base or auto hydrolysis, in single stage or dual stage configuration. With minor upgrades, the hydrolysis unit can incorporate other pretreatment chemicals and configurations. ...

-

Manufactured by Aemetis, Inc.based in USA

We produce a low-carbon ethanol fuel alternative from corn and biomass. Our low-carbon ethanol is a clean-burning, high octane, renewable fuel produced from abundant agricultural and cellulosic feedstocks. Ethanol is used as an effective octane-boosting fuel additive or high-blend fuel. Ethanol is the only low-carbon alternative to gasoline available today. All comparisons to gasoline demonstrate ...

-

Manufactured by BioRefinex Canada Inc.based in CANADA

Once commissioned, the Lacombe Biorefinery will be producing biogas to provide enough fuel for a 1.4MW power generation unit. This renewable energy source, comprising mostly methane (natural gas), will be produced using large anaerobic digester vessels. The biogas is produced by micro-organisms breaking down organic matter in an oxygen-free environment. Biogas can be produced from materials ...

-

Manufactured by SteEnova GmbHbased in GERMANY

Only gasification allows to convert solid biomass to reach high efficiency in combined heat and power generation in the decentralized sector. Due to this Seenova has developed an fluidized bed gasifier which was optimized and tested and ready for market ...

-

Manufactured by Bioenergy and Sustainable Technologies GmbH (BEST)based in AUSTRIA

The utilization of biomass, residues and waste by thermo-chemical gasification is the core of this competence area. Through the gasification process we convert biomass, residues and waste into syngas; this is the basis of synthetic fuels (FT diesel, FT kerosene, methanol), gaseous energy carriers (hydrogen and synthetic natural gas) or chemicals. Using renewable raw materials (biomass, sewage ...

-

Manufactured by Chevron Renewable Energy Groupbased in USA

A reliable solution for high-quality products. Chevron Renewable Energy Group Glycerin is a high-quality, consistent co-product from biodiesel production that Chevron Renewable Energy Group strategically markets domestically and internationally from a growing network of biorefineries. ...

-

Manufactured by Sekabbased in SWEDEN

Sugar from lignocellulose: Sekab’s CelluAPP technology comprises process technology for the production of sugar solutions from lignocellulose. Basically, the raw material is pretreated so that sugar is released and the crystalline structure of the cellulose is broken down. More sugar is released through enzymatic hydrolysis. Using our CelluAPP technology we can extract cellulose sugar. ...

-

based in GERMANY

The Biofabrik Green Refinery Biorefinery was developed over a period of more than 12 years. Based on a process developed at the University of Linz, Biofabrik’s series production plant, business model and products were brought to production ...

-

based in ITALY

Success in cellulosic ethanol constitutes a feat with which Biochemtex, affiliate of the Mossi & Ghisolfi Group, challenged the chemistry world, already back in 2006. With a total investment exceeding 150M€ and over 7 years dedicated to research and development within the R&D center of Rivalta Scrivia in Italy, Biochemtex created Proesa™, a socalled “second ...

-

Manufactured by Sekabbased in SWEDEN

Using our biorefinery technology we can decompose cellulose. Cellulose is a carbohydrate that forms the major part of all plants’ cell walls and is thus the most common organic substance in nature. Cellulose is relatively hard, making plants stiff and steady. The plant fibres consist almost entirely of cellulose and can be utilised by man in many ways. For example, the fibres of linen and ...

-

Manufactured by Sekabbased in SWEDEN

This is how we can make sugar and ethanol from cellulose. The process developed by Sekab E-Technology consists mainly of four steps: pre-treatment, enzymatic hydrolysis, fermentation and reprocessing. When the raw material has come into the plant, it is transferred to a vessel where it is pre-treated with acid and steam at a temperature of 200 degrees. This releases sugars from the hemicellulose. ...

-

Manufactured by Enerkembased in CANADA

A biorefinery with the lowest production costs compared to alternatives. Consider an Enerkem biorefinery as your solution for domestic clean energy and sustainable waste ...

-

Distributed by RENEW ENERGY A/Sbased in DENMARK

The biogas production technology is RENEW ENERGY’s basic model manifested in RENEW ENERGY’s separation plants and biorefineries in combination with ethanol plants. Bacteria convert biomass into valuable fertilizers and environmentally friendly biogas. Examples of biomass are livestock manures and organic residuals such as waste from food industries. Fertilizers are sent to farmers who ...

-

Manufactured by Bio Energy Shanghai Co., Ltd (BioGTS)based in CHINA

BioGTS Biorefinery Biorefinery is a new biorefinery concept that can efficiently process organic waste and convert it into renewable energy, motor vehicle biomass fuel, chemicals and fertilizers. This concept is based on the innovative combination of biodiesel and biogas ...

-

Manufactured by Bioenergy and Sustainable Technologies GmbH (BEST)based in AUSTRIA

Thermochemical conversion of biomass enables the production of energy (heat and electricity) as well as the co-production of renewable carbon products (biochar, bio-oils and gases) for a wide range of applications (e.g. agriculture, plastics production or metallurgy). Sub-Area 1.1 Thermochemical Technologies focuses on the development, optimization and demonstration of pyrolysis, gasification and ...

-

Manufactured by Bioenergy and Sustainable Technologies GmbH (BEST)based in AUSTRIA

Our work on biotechnological conversion follows the principle of cascading utilization. We develop biotechnological processes for the conversion of biomass, residues and CO2 to various products (gaseous or liquid energy carriers, basic chemicals, higher value products for the chemical industry, ...

-

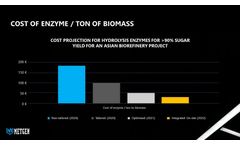

by MetGenbased in FINLAND

Biomass comes in many forms. Affordable processing requires us to fractionate the biomass to its basic components as thoroughly as possible with the lowest cost. With this in mind, the material in the process is always a unique combination of feedstock and pretreatment. Therefore, the enzymes must be tailored for the task as well. Biomass is not oil – it’s the soup of the day. MetGen ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you