Agraferm Technologies AG

Agraferm Technologies AG, which is based in Pfaffenhofen, Germany, designs and builds Anaerobic Digestion plants. It is one of the few full service providers of turnkey agricultural and industrial biogas plants in Europe, which operates internationally. Our portfolio includes project planning and construction as well as biological and technical services.

Company details

Find locations served, office locations

- Business Type:

- Service provider

- Industry Type:

- Bioenergy

- Market Focus:

- Internationally (various countries)

About Us

Agraferm Technologies AG, which is based in Pfaffenhofen, Germany, designs and builds Anaerobic Digestion plants. It is one of the few full service providers of turnkey agricultural and industrial biogas plants in Europe, which operates internationally. Our portfolio includes project planning and construction as well as biological and technical services.

We are committed to the long-term success of our customers through

- Planning, construction and service from one source

- Biological and technical support services

- Many years experience with CHP-units and biomethane feed-in systems

Our Know-how

Agraferm biogas plants have the following distinctive features...

- High reliability and maximum system availability

- Use of robust components such as fermenters, agitators and pumps

- Stable fermentation process

- Industrial-quality plant construction

The advantages for you

- Minimum operating costs

- Optimum level of substrate flexibility

- Minimal risk of downtime

- Maximum cost-efficiency

Dimensioning

A biogas plant is more than just a big pot, in which you put substrate with biogas and residue coming out. The flow of digestion substrate requires a certain minimum retention time in the digester, regardless of the breakdown kinetics of the feedstock, so as not to endanger the stability of the biocenosis and to guarantee a minimum return. Dry substrate and substrate with a low gas yield particularly often require the addition of process water in the digester to ensure that the mixture can continue to be stirred, whereas water is pressed out of digested sludge using screw press separators so that the volume of liquid residue can be reduced. Agraferm ensures that all initial quotations already contain a complete mass and energy balance (MEB). The sizes of the digester, the secondary digester and the final storage tanks as well as the pumps, separators and pipes are selected based on this MEB and are quoted with the correct dimensions and prices.

The detailed pre-planning we do when preparing a quotation, give us, and our customers, early cost assurance. Thus avoiding the need for a safety margin in the calculation or any later surprises or extra costs. Strict design guidelines ensure that the plant creates sufficient return and is capable of delivering full performance even if a different substrate is used at a later stage.

Dry Fermentation

Agraferm biogas plants are often described as dry fermentation plants due to a higher dry matter content in the digester. Depending on the substrate, the dry matter content can be between 10% and 18%. The digesters are constantly in operation and Agraferm plants can process stackable substrate just as well as liquid substrate.

For the day to day running of a plant the difference between dry and wet substrate is no longer relevant. Whether with stackable or pumpable substrate, the biogas plant must be capable of mixing the biomass thoroughly. The shift from the “dry-fermentation bonus” to the “slurry bonus” shows us that the range of substrate available can change quickly throughout the life cycle of a biogas plant. Very few biogas plants operate for 20 years using the same range of feedstock. Agraferm plants have durable mixers and sufficiently long retention times so that lower quality substrates can be processed in the future.

The Paddle Mixer

Agraferm reacted to the change in the choice of feedstocks by developing the durable paddle mixer. While conventional biogas plants are restricted to slurry, maize or sugar beet due to the use of the submersible mixer, Agraferm plants have a much wider choice of substrate at their disposal. In the increasingly restricted and scarce substrate market operators of Agraferm plants can use feedstocks which the others cannot use at all or only in a very limited way. The highly developed Agraferm paddle mixer meets this challenge in particular, especially against the background of the current renewable-energy law 2012, which will begin by restricting the level of maize allowed in biogas plants.

Maintenance without emptying the digester

The agitator shaft and the motor are installed from the outside through an opening in the digester lid. This makes it much easier to de-install and re-install the agitator shaft for maintenance, as it is not necessary to empty or even partly empty the digester. Agraferm mixers are constantly being developed. By reconstructing a mixer on a laboratory scale Agraferm is able to successfully up or downscale a digester. The mixers can be designed and specified using dimensioning analysis and the torque and energy consumption can be predicted accurately. We now have extensive data on the rheological behaviour of the highly viscous three-phase biomass. Current research is further deepening our knowledge and ensuring that Agrafern continues to be the market leader for highly viscous digestion. Agraferm was successful in receiving an EU patent for this technology.

Research and Development

Agraferm aims to make a significant contribution to the global energy movement through the use of biomass to produce energy, and to this end take advantage of its many years experience in the construction of biogas plants. Socio-political dialog has increasingly led to the questioning of renewable raw materials being used as standard feedstock for the production of biogas. This is why Agraferm has focused its attention on the fermentation of certain industrial waste products as well as the production of biogas from agricultural products and waste.

The current challenges Agraferm has set itself are in the microbiological and technical aspects of processing biomass in order to advance the biogas industry and to constantly update the technology. For this reason Agraferm will undertake innovative research projects with scientific and industrial partners with the results being published in the industry. Here is an extract from the research and development projects we are currently planning.

Energy from biomass – new ways to integrate biorefineries

Sponsored by the German Ministry of Education and Research on the basis of a resolution passed by the German Federal Parliament.

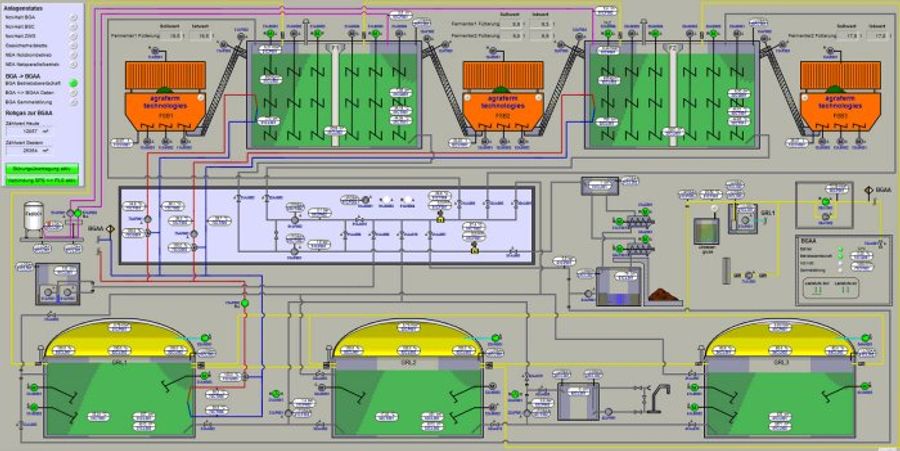

Agracontrol

Biogas plants operate with sensitive process windows. This means that if a parameter changes operators must be able to recognise this early and react quickly. Agracontrol, a subsidiary of Agraferm Technologies AG, supports you as a competent partner for you biogas applications with their automation solution “agracontrol green” offering services which include control technology, process technology, fault transmission, reporting, servicing and distance maintenance.

Our “agracontrol green” control software and technology, which was developed in-house, is unique and can be used for small and mid-sized installations as well as industrial scale plants. It brings together all of Agraferm Technologies’ essential experience in the automation of processes in the production of biogas. “agracontrol green” controls the following processes for you:

- All important parameters relating to the input and timing of feedstocks

- Monitoring and documentation of filling levelsAutomation of pumps and mixers

- All data presented comprehensively on screen

- Visual presentation ensures timely recognition and rectification of possible process malfunctions

- Monitoring of gas quality and automatic notification of faults via transmission to a remote unit.

Automation

Automation

This module controls the sequence of the process in the plant and its current behaviour and as such is the heart of the plant. The software, which was developed by Agraferm, is based on Siemens Step7 and uses a stored-program control system.

Process monitoring system

The interface provides a visual representation of the process in the plant. This is installed on a panel PC or desktop PC depending on the plant design. The monitor displays an easy-to-understand representation of the process in the plant. The user can choose between numerical values, graphical symbols, colour or bar charts to view the current status of all stages of the process, such as container levels, temperature of the process media and the flow rates through the pipe systems.

Reporting

An additional reporting module is also installed on the control computer to assess the efficiency of the plant. This tool is used to collect, archive and evaluate the operating data.

Service and maintenance

There is a further module on the control computer for administration and for preventative maintenance which offers the following functions:

- Manage summary of current status

- Maintenance summary

- Annual report of maintenance

- Manage aggregate temperatures

- Administration of historical reports

- Administration of aggregate related documents

- Input and administration of values recorded by hand.

Fault notification

The fault notification module sends fault messages from the process control system to a mobile phone, fax machine or via email. It provides constant monitoring of the plant especially when the operating personnel are absent.

Distance maintenance

The distance maintenance module allows the operator to monitor the plant from a distance. This module also enables the technical and biological staff of Agraferm to fully monitor the plant.

The remote monitoring system “agracontrol green” from Agracontrol is a service that can be used for older plants as well as new biogas plants.