JD Turbulators B.V

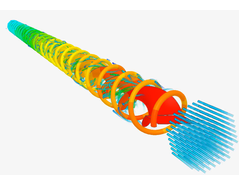

Energy efficiency has become an increasingly important theme in the cooling and heating industry. For many years turbulators have been an important means to improve convective heat transfer in tubular heat exchangers and thereby increase the overall efficiency of the system. In addition to saving on energy use, it also helps to reduce the size, weight and cost of equipment. The product group of JD Turbulators has grown its expertise in heat transfer enhancement with the use of turbulators for more than 40 years, working with many global heating companies and heat exchanger equipment manufacturers. With our turbulators we offer a very practical and cost-effective solution for increasing the efficiency of gas boilers, biomass boilers, air heaters, coolers and a broad range of other tubular heat exchangers systems. We make turbulators in a wide range of geometries, dimensions and materials offering the best efficiency solution for many tubular heat exchanger systems.

Company details

Find locations served, office locations

- Business Type:

- Manufacturer

- Industry Type:

- Energy

- Market Focus:

- Globally (various continents)

- Employees:

- 11-100

- Turnover:

- $1,000,000 US - $10,000,000 US

Welcome

Turbulators are a very practical and cost effective solution for increasing the efficiency of gas boilers, biomass boilers, air heaters, heat exchangers and a diverse range of other applications. We make turbulators in a wide range of geometries, dimensions and materials offering the best efficiency solution for many tubular heat exchanger systems.

THE BENEFITS OF APPLYING TURBULATORS

- Significant increase in efficiency upto 18%

- More compact and lightweight design

- Cleaning the fluepipes of scale deposits

- Major savings in fuel costs

- Reduced carbon footprint

- Comply to the latest energy directives

INNOVATION

We understand the fundamentals of heat transfer enhancement with turbulators and its applications in industry. We continualy find new opportunities to exploit our proven technology together with our customers.

FLEXIBLE

Flexible production methods enables us to produce the best type of turbulator for a broad scope of applications. By incorporating the production of turbulators in to our state of the art metal welding and assembly plant we are able to produce quickly and effectively.

PARTNERSHIP

We understand our customers heat transfer challenges, listen to their needs, offering solutions which provide you with a competitive efficiency advantage.

QUALITY

The productgoup of JD Turbulators has grown its expertise for more than 40 years, working with many global heating companies and heat exchanger equipment manufacturers. Our extensive experience helps us to find the best solution for your specific heat transfer problems.

About us

Appropriate design and utilization of turbulators is important for optimal system performance. By incorporating the production in to our own state of the art metal welding and assembly plant in Raamsdonksveer, we are able to produce quickly and effectively due to very short lines of communication between sales, development and production. We’re happy to help you with a solution for your specific heat transfer problems. Please call or email us for sample requests, heat transfer calculations or define your dimensional requirements and request a quote.

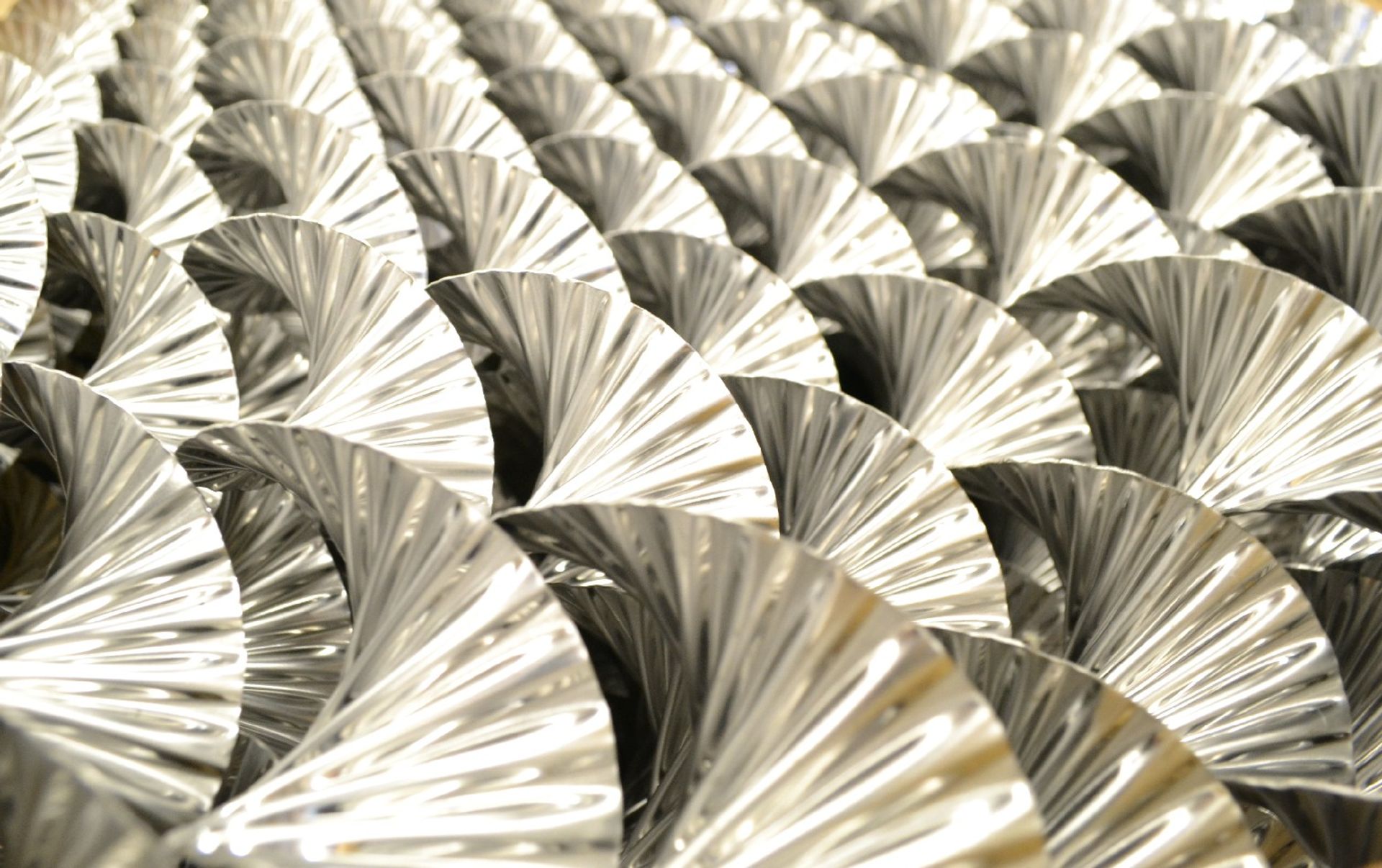

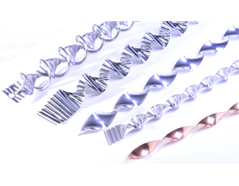

Our Turbulator Products

We make turbulators in a wide range of geometries, dimensions and materials offering the best efficiency solution for many heat exchanger systems. According to the customers requirements we make a proposal for the turbulator design and a quote based on the needed quantities. On request we can make performance calculations and provide samples for testing the effect the turbulators will have on the performance of the application at hand.

Turbulator Applications

Increasing efficiency is of benefit for manufacturers of various heat exchanger applications. JD turbulators has experience with the manufacturing of turbulators for many different types of tubular heat exchanger applications. Solid and gas fueled boilers and convective air heaters are the most general applications. Yet, the applications we have experience with are numerous.