PicoParts Ltd.

Pico Parts is a manufacturer of small precision products made from a wide selection of materials and serving customers all over the world. Our main specialties are Tungsten Carbide and technical Ceramics parts, made with Cold Pressing, Isostatic Pressing, Injection Molding, Extrusion, and Sintering Technologies. Pico Parts, a sub-contractor driven by customer’s needs, serves customers in a wide range of industries such as Aerospace, Painting, Medical, Agriculture, Precision Measuring Equipment, Dental, Pressure Washers, Micro-Electronics, Printing and more.

Company details

Find locations served, office locations

- Business Type:

- Manufacturer

- Industry Type:

- Metal

- Market Focus:

- Globally (various continents)

About Us

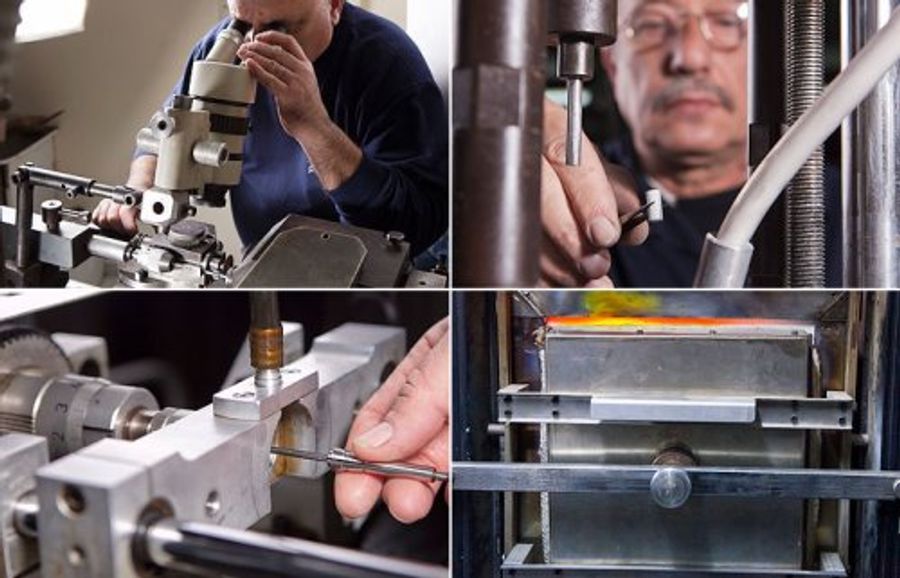

VAST EXPERIENCE AND KNOW-HOW

PicoParts' years of experience with special materials, sophisticated technologies and the innovative thinking of our staff, allows us to meet even the most intricate technical challenges. We use a wide range of technologies such as powder metallurgy, laser cutting, vacuum brazing, welding, lapping and precision dimensional grinding to very tight tolerances.

We use a wide variety of powders, and control the full cycle of the manufacturing process in house. Pico Parts works with other ferrous and non-ferrous materials such as Titanium, Kovar, Glass, different Steels, Nitinol and more.

JUST IN TIME DELIVERY

Dealing with small precision parts, PicoParts is capable of holding stock for its customers and thus provide Just in Time Delivery. Our products reach our worldwide customers within a few days by working with leading courier companies such as TNT, UPS and DHL. Israel’s free trade agreement with the European Union makes commercial interactions as easy as if we were another country in the European marketplace.

QUALITY

PicoParts' reputation as a highly accurate products manufacturer has been achieved due to its uncompromising attitude towards quality control and on-going improvement. PicoParts' quality control department monitors every aspect of the product lifecycle: product design inception, powder humidity control, received goods acceptance, in-process examination and final inspection and approval are just a few of the QC department’s day to day tasks. Our emphasis on quality is one of the reasons for our ability to produce superior products in a repeatable and reproducible manner. As a result PicoParts is an ISO 9001 certified company.

WORKING ENVIRONMENT AND LIFESTYLE

PicoParts invests a lot of effort to create a safe and pleasant environment for its employees. Our employees go through periodic safety training in order to reduce the probability for injury. PicoParts controls the Air-Industrial Hygiene as well as Acoustics Measurements (ISO 9612:1997) by performing sampling examinations in external laboratories approved by Israel’s Ministry of Industry, Trade and Labor. At PicoParts we believe each person should have the opportunity to earn a living thus we declared PicoParts to be an Equal Opportunity Employer.

Technologies

The challenges created by our customers’ needs regarding material, tight precision tolerances and geometrical complexities, require PicoParts to use a large set of unique and sophisticated technologies. These are the reasons why PicoParts possess all the required technologies to manufacture Tungsten Carbide, Ceramic and other hard-material parts. Production starts with technologies such as Powder Metallurgy, cold and hot pressing, injection molding and extrusion. We then proceed to sintering using vacuum furnaces for hard-metals and dedicated accurate-temperature furnaces for ceramics. Following the sintering phase we use grinding, polishing, electro-erosion and laser welding among additional technologies.

The wide range of serviced markets and the fast pace of technology changes initiated by our customers, dictates a rapid and constant adoption of new technologies, R&D procedures and accompanying technical equipment. Therefore PicoParts is among the selected few companies worldwide that are able to manufacture sophisticated precision parts made from hard-materials, starting from powder and continuing to final finished goods.