Heat Exchangers Articles & Analysis

-

Use of High Purity Copper in New Energy and High-Tech Fields

High-purity copper (usually refers to a purity of 5N to 7N, i.e. 99.999% to 99.9999%) is a metal material with excellent physical and chemical properties. Properties of high-purity copper Electrical conductivity and thermal conductivity: High-purity copper has extremely high electrical conductivity and thermal conductivity, which makes it very useful in electronic and thermal management ...

-

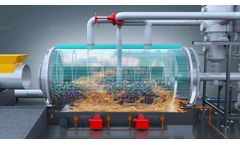

The Role of Thermal Efficiency in Pyrolysis Reactor Performance

The thermal efficiency of a pyrolysis reactor is a critical factor in determining the overall performance, energy consumption, and economic feasibility of the pyrolysis process. Pyrolysis, a thermochemical decomposition process, is used to convert organic materials such as plastics, rubber, and biomass into valuable products like oil, gas, and charcoal. The efficiency with which the reactor ...

-

9 Questions to Ask Your Heat Exchanger Supplier

Heat exchangers are commonly used for a wide range of purposes in the anaerobic and biogas sector, from digester heating and pasteurisation to evaporation, biogas dehumidification and exhaust gas heat recovery. With a wide range of types and designs available from numerous manufacturers, choosing the right solution, from the right supplier, can seem daunting. However, posing the right questions ...

-

Products Used in Geothermal Heat Pumps and Solar Thermal Systems

As we continue to innovate and adopt cleaner energy technology, renewable energy technologies are increasingly vital in our quest for sustainable and efficient energy solutions. Among these technologies, coil heat exchangers play a crucial role in enhancing the performance and efficiency of systems like geothermal heat pumps (GHPs) and solar thermal ...

By Fluorostore

-

RTO Regenerative Incinerator - Case Study

Regenerative Thermal Oxidizer (RTO) uses the ceramic regenerators to store the heat generated by the decomposition of VOCs, and uses the thermal energy stored in the ceramic regenerator to pre-heat and decompose the untreated VOCs, thereby achieving high thermal efficiency. The oxidation temperature is generally between 800 ° C and 850 ° C, up to 1100 ° C. Regenerative Thermal ...

-

VOCs Treatment RTO Incinerator - Case Study

Regenerative Thermal Oxidizer (RTO) uses the ceramic regenerators to store the heat generated by the decomposition of VOCs, and uses the thermal energy stored in the ceramic regenerator to pre-heat and decompose the untreated VOCs, thereby achieving high thermal efficiency. The oxidation temperature is generally between 800 ° C and 850 ° C, up to 1100 ° C. Regenerative Thermal ...

-

coal mine solutions

Recently, varelen design and developed mine flameproof dry transformer with active heating pipe, the company's full wave mine flameproof dry transformer products were upgraded again, creating a new era of flameproof heat dissipation. Varelen Electric enables product innovation with science and technology, helps the industry technology climb the peak, and promotes new changes in the flameproof ...

-

High voltage low lossess 66KV transformer

Introduction The wind energy sector has seen tremendous growth and innovation over the past few decades. From modest beginnings in the 1990s, where wind turbines produced a mere 0.5 MW of power, today’s turbines are capable of generating over 10 MW. Despite these advancements, the voltage output of wind turbines remained at 33 kV for many years. However, a significant shift occurred in 2017 ...

-

How to Properly Maintain a Pyrolysis Reactor

A pyrolysis reactor is a sophisticated piece of equipment used to thermally decompose organic materials in an oxygen-free environment, yielding valuable products such as bio-oil, syngas, and biochar. Proper maintenance of a pyrolysis reactor is critical to ensure its efficient operation, longevity, and safety. This article provides a detailed guide on how to properly maintain a pyrolysis reactor, ...

-

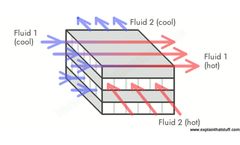

Choosing the Right Heat Exchanger for Food Processing

All but the most basic heat exchangers are created to a bespoke brief, designed to take into account the material/s being heated or cooled, the heating or cooling medium, the amount of product being processed, product velocity, risk of fouling and a host of other factors. However, over the years some standard design types have emerged (as well as more specific types) and understanding the ...

-

Factors Influencing the Selection of Pyrolysis Reactor Materials for Continuous Pyrolysis Plant

The choice of materials for the pyrolysis reactor in a continuous pyrolysis plant is a critical decision that directly impacts the efficiency, durability, and safety of the pyrolysis process. Several factors must be considered when selecting the appropriate materials for the reactor, ensuring optimal performance and longevity. In this comprehensive analysis, we explore the key factors that ...

-

What Are the Characteristics of Stainless Steel Corrugated Plate?

Stainless steel corrugated plates have several key characteristics, including: 1. Efficient Heat Transfer: The thin, corrugated stainless steel plates used in the design of heat exchangers provide efficient heat transfer with an extremely small footprint, making them ideal for demanding installations where space is at a premium. 2. High Pressure and Temperature Resistance: The brazed plate heat ...

-

Considerations Regarding the Wood Charcoal Making Machine

Did you know there's a lucrative way to manage the vast amount of wood waste generated by the manufacturing and construction industries every year? Have you been wondering what can be done with the mountains of wood scraps and other organic waste that would otherwise end up rotting in a landfill? A Beston wood charcoal making equipment for sale could be the solution to turn unusable wood into ...

-

Beef Processing Plant Case Study | Stack Economizer

Project Overview A beef processing plant has recently partnered with Kemco Systems to recover heat exhaust from its facility’s water-sanitization boilers. Priding itself on a sustainable mindset and strict operational standards, the beef processing company reached out to Kemco through a channel partner. This company was seeking updated equipment to continue production of the highest-quality ...

-

Keeping Battery Production Profitable and Green - Case Study

Batteries have become a key contributor in the world’s energy transition and critical in the effort to slow climate change. As a result, battery manufacturing technologies and techniques are constantly evolving as producers look to remain competitive, increase storage capacity, and improve efficiency while decreasing battery size and weight. For instance, some producers are turning to a ...

-

The Continuous Pyrolysis Plant: An Ideal Opportunity

The continuous pyrolysis plant carries a screw feeding sealing system, that is characterized by high heat exchange efficiency and capacity. Its electrical product is also impeccably controlled. It realizes zero emissions and will be fed with any fuel. The hot air flowing in to the reactor gets hotter the fuel. The finished items are clean and odorless. It may also be used to recycle waste ...

-

A Great Project Delivered in Liepaja - Case Study

Year 2022 EcoHeat Technologies (Steel Pro) delivered another biomass driven container type energy plant with a comprehensive fuel supply system. This time – in Liepaja, Karosta. The facility will deliver energy for district heating in autumn 2022. Since, in procurement we’ve been awarded with the contract, we are incredibly happy to have “LIEPAJAS ENERGIJA” as our ...

-

Guide to designing a passive house for summer comfort

If you live in a conventional house, you certainly know what thermal discomfort means. During the hot summer days, the building heats up so much that even at night it does not cool down enough, and the atmosphere does not become comfortable. Using air conditioning involves additional electricity consumption and higher costs. The increase in energy prices causes us to analyze various solutions ...

-

How to Use the Waste Heat in Your Factory as an Energy Source

Modern factories are investing in technology to reduce their energy consumption, costs and CO2 emissions. This is not new, but the process of digitalisation and decarbonisation has accelerated to meet global energy transition and sustainability goals.In addition, the constant increase in energy costs pushes companies to become more efficient and reduce overall expenditure to stay competitive. If ...

-

Taking the heat out of Geothermal Production

As the geothermal energy market heats up, techniques pioneered in the Middle Eastern desert could dramatically boost geothermal production rates-helping unlock a potentially vast global resource. Gary MacDonald, Middle East-based Global Business Development Manager with OSSO, a provider of specialist fluid temperature control and separation solutions, assesses how mud cooler techniques could ...

By Osso Ltd

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you