Tube Heat Exchangers Articles & Analysis

-

9 Questions to Ask Your Heat Exchanger Supplier

Heat exchangers are commonly used for a wide range of purposes in the anaerobic and biogas sector, from digester heating and pasteurisation to evaporation, biogas dehumidification and exhaust gas heat recovery. With a wide range of types and designs available from numerous manufacturers, choosing the right solution, from the right supplier, can seem daunting. However, posing the right questions ...

-

Choosing the Right Heat Exchanger for Food Processing

All but the most basic heat exchangers are created to a bespoke brief, designed to take into account the material/s being heated or cooled, the heating or cooling medium, the amount of product being processed, product velocity, risk of fouling and a host of other factors. However, over the years some standard design types have emerged (as well as more specific types) and understanding the ...

-

Biogas Cleaning

Removal of water vapor Origin In the biogas production process, water is an intrinsic part of both the material to be digested (biomass) and the process itself. Furthermore, water is the medium in which biogas production takes place, regardless of whether the digestion process is dry or wet, the biogas produced will contain water vapour. The amount of water vapour contained in the biogas ...

-

Evaporation Increases Capacity for Drying Cheese

A novel use of evaporation using heat exchanger technology from HRS Heat Exchangers has increased drying capacity for a major European processor of cheese products. ...

-

HRS Helps Orange Juice Producer Exploit Novel Pasteurisation Techniques - Case Study

HRS Heat Exchangers has supplied a leading Mexican orange juice producer with a complete pasteurisation system that uses a novel electrical heating method – Ohmic. The new system maintains the properties of freshly squeezed juice, which are adversely affected during traditional pasteurisation processes, allowing the company to increase its presences in the lucrative North American ‘as ...

-

The Engineering Behind Shell and Tube Heat Exchangers and Their Benefits

Shell and tube heat exchangers are used for the flow of in-line heating and cooling. The innovative design allows the movement of fluids through the tubes and exterior shell delivering changeability. The movement of fluid can be run in a counterflow, cross flow, or parallel mode. The flow of the fluids can not be reversed, so the development of dirty pockets is then eliminated during the ...

By Fluorostore

-

New Juice Processing Solutions: from Concentrate to Bottle - Part 2

Pasteurisation High Temperature Short Time (HTST) pasteurisation, also known as ‘flash pasteurisation’, is the preferred technique for making premium quality juice. The HRS series of MI/MR pasteurisers uses a food-grade, multitube corrugated tube heat exchanger to speed up the heat transfer, while the corrugated tubes create extra turbulence in the juice as it flows through. This ...

-

Introducing AHED (Advanced Heat Exchanger Design)

AHED (Advanced Heat Exchanger Design) is a powerful design tool for the calculation of one of the most used items of process equipment: shell and tube and heat exchangers (STHE’s). STHE’s are used in widespread process industries including Chemical, Oil & Gas, Wastewater, Food, Pharmaceutical & Automotive. The design of STHE’s is fundamental for a process installation ...

-

Choosing the right heat exchanger for wastewater applications

Heat exchangers are crucial to many processes in the water industry, in aerobic or anaerobic digestion plant, for cooling or evaporation, and for sludge concentration. Choosing the right heat exchanger can appear daunting, and maximising productivity is ...

-

Fossil and Nuclear NDT Solutions for the Power Industry

Power generation means unleashing vast energy, transforming it, and harnessing it. Fossil fuel power plants tap into organic materials formed over the course of millions of years. Nuclear energy is an emissions-free source that comes from splitting atoms in a reactor to power industry and homes. When working with such colossal forces, it’s vital that the equipment and machinery used are ...

By Zetec, Inc

-

Multiple uses for heat exchangers in brewing

There are numerous uses for heat exchangers in breweries, from cooling, pasteurising and fermenting products, through to efficiently dealing with waste streams such as yeast slurry. Compared to other methods of heating, heat exchangers can be much more energy efficient, providing both environmental and economic benefits. One of the first uses of heat exchangers in brewing is for rapidly cooling ...

-

Corrugations best for efficiency in tubular heat exchangers

There are many different types of tubular heat exchanger on the market, such as annular space, double tube and multitube, as well as those with different geometries including the use of internal fins, dimples and corrugations. We have written several articles explaining why corrugated tubes are our preferred design option, but it is worth ...

-

HRS helps AD plant tap into additional heat from existing CHP

Operators of anaerobic digestion (AD) plants know how important it is to optimise energy use across all stages of the process. That is why many recapture as much heat as possible for reuse elsewhere, including from the hot exhaust gases generated by the combined heat and power (CHP) engines which turn the biogas from the AD plant into useful heat and electricity. Heat exchangers used for exhaust ...

-

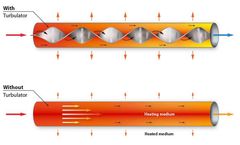

The value of increasing the efficiency of tubular heat exchangers by using turbulators

Introduction Heat transfer enhancement in all types of heat exchanger systems is of great significance for the cooling and heating industry. In addition to saving energy, it also leads to a reduction in size and weight of equipment. In the last decade energy efficiency has become an increasingly important theme among policy makers as it can enable economic growth, reduce emissions and improve ...

-

Preventing product contamination with double tube plate heat exchangers

Ensuring product safety is the number one priority for any producer of pharmaceutical products, and a key aspect of this is avoiding contamination during production. Design and construction plays a key role in achieving this, and the heat exchangers used for processes such as pasteurisation and sterilisation are no exception. There are three main elements to preventing contamination occurring in ...

-

See how the HRS R Series saves valuable space, time and energy

HRS Heat Exchangers’ Cameron Creech, General Manager for HRS North America, explains why the HRS R Series is a better option than traditional single tube scraped surface heat exchangers. The R Series Scraped Surface Heat Exchangers have been designed to maximise energy and product recovery, reduce footprint and be cost effective to maintain. For highly viscous products, the RHD Series is a ...

-

Spiral or corrugated tube heat exchangers - which is best for wastewater treatment?

Since the first spiral heat exchanger was proposed back in the 19th century, they have become synonymous with the treatment of slurries and wastewater. However, in many situations the performance of a corrugated tube heat exchanger is equal to or better than that of a spiral design. Corrugated tube designs also provide a number of additional advantages in terms of day-to-day operation and ...

-

Understanding and preventing heat exchanger fouling

When operating in exceptionally challenging conditions, or handling difficult materials such as sewage and wastewater sludges, even the best designed heat exchangers will be susceptible to fouling. Understanding the different types of fouling and what causes them will help engineers and operators pick the best type of heat exchanger for their particular application and keep it running in optimum ...

-

The Straight Test Straight Tube Heat Exchanger - Case Study

The Client The client is an international integrated energy company with operations in 33 countries and are operating and developing their SAGD Assets in the Athabasca oil sands region. As in all SAGD operations the bitumen is brought to the surface mixed with particulate and water. The exchangers that do the initial cooling of this mixture are regularly fouled by the bitumen and particulate. ...

-

The Stubby Bitumen - Twisted Tube Heat Exchanger - Case Study

The Challenge Twisted tube designed heat exchangers are exceptionally difficult to clean. This particular fouling process is extra challenging due to the steam in the tube side which bakes the bitumen on to the shell side faster than other designs. This heat exchagner was brought to ABSOLUTE after a previous service provider was not successful in their attempt to clean it. When previously ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you