Pyrolysis Articles & Analysis

-

Power of Biochar Pyrolysis in Carbon Removal

Biochar pyrolysis is a thermochemical process that involves heating biomass - materials such as wood, agricultural waste, or dedicated energy crops - in an oxygen - limited environment. As the biomass is heated to temperatures typically ranging from 300°C to 800°C, a series of complex chemical reactions occur. The biomass decomposes, releasing volatile gases like methane, hydrogen, and ...

-

Catalytic Pyrolysis for Superior Pyrolysis Oil Quality

Catalytic pyrolysis is a modified version of the traditional pyrolysis process. While traditional pyrolysis relies solely on heat to break down organic materials, catalytic pyrolysis introduces a catalyst into the reaction system. The catalyst acts as a facilitator, lowering the activation energy required for chemical reactions to occur. This not only speeds up the pyrolysis process but also ...

-

Enhancing the Quality of Barbecue Charcoal Production

The quality of barbecue charcoal is paramount for a superior grilling experience. High-quality charcoal ensures consistent heat, minimal smoke, and extended burn time, which are crucial for grilling food to perfection. Achieving the desired quality requires attention to various factors during both the production and processing stages. From raw material selection to machine efficiency, several ...

-

Biochar Carbon Credit Trade: Why It Matters

The global fight against climate change has spurred innovative solutions to reduce carbon emissions and enhance carbon sequestration. Among these, biochar carbon credit trade is emerging as a promising mechanism to incentivize sustainable practices while mitigating climate change. But why does it matter? This article delves into the significance of biochar in the carbon credit market, its ...

-

Maximizing Profits with Biochar Machine Technology

The growing interest in sustainability and resource efficiency has positioned biochar production as a key element in the circular economy. A biochar machine offers an efficient way to convert organic waste into high-value products that benefit both the environment and the economy. The versatility of biochar, combined with the increasing demand for eco-friendly solutions, makes investing in ...

-

Role of Biochar Pyrolysis Production in Promoting Carbon Trading

Carbon trading is an innovative approach to addressing climate change, enabling organizations and nations to offset their carbon emissions by investing in carbon reduction or sequestration projects. Among these, biochar pyrolysis production has emerged as a powerful tool in reducing greenhouse gas emissions while promoting sustainable agricultural practices. Biochar is a carbon-rich material ...

-

Key Considerations in Biochar Production Equipment Pricing

Biochar production has become an essential part of the sustainable waste management and renewable energy sectors. With its capacity to sequester carbon and improve soil health, biochar holds significant value in environmental and agricultural applications. However, the investment required to acquire biochar production equipment can vary greatly, depending on several critical factors that ...

-

Sustainable Breeding: Biomass Litter & Manure co-pyrolysis

Agriculture faces an increasing challenge in managing waste, especially manure-contaminated biomass litter. This waste is generated in vast quantities and often disposed of through inefficient or environmentally damaging methods. Pyrolysis, a thermal decomposition process conducted in the absence of oxygen, has emerged as a promising solution for converting biomass waste, including ...

-

The Role of Plastic Naphtha in the Petrochemical Industry

Plastic naphtha is a hydrocarbon-rich liquid derived from the pyrolysis of plastic waste. This valuable byproduct serves as an intermediate in the production of various chemicals, including gasoline and other fuels. Its production, largely driven by the ongoing need for sustainable waste management solutions, plays a critical role in the circular economy, offering a route to reduce plastic waste ...

-

Secrets of Biomass Pyrolysis: Understanding Material Chemical Composition

The process of pyrolysis has gained significant attention as a method for converting biomass into valuable byproducts like biochar, syngas, and bio-oil. Pyrolysis, which involves heating organic material in the absence of oxygen, is not only a promising solution for waste management but also a way to produce renewable energy. However, to truly harness the full potential of this technology, it is ...

-

Biomass Gasification vs. Pyrolysis: What Sets These Two Technologies Apart?

When exploring renewable energy solutions and waste-to-energy technologies, two methods often emerge in discussions: biomass gasification and pyrolysis. While both processes involve the conversion of organic materials into valuable energy, they operate on different principles and produce distinct outcomes. Understanding the differences between biomass gasification and pyrolysis is crucial for ...

-

Is Pyrolysis a Continuous Process?

Pyrolysis is a thermal decomposition process that breaks down organic materials, such as plastic, rubber, and biomass, in the absence of oxygen. This process has gained significant attention for its potential in waste management and resource recovery, offering an effective way to convert waste into valuable products like fuel, gas, and biochar. A key question that often arises is whether ...

-

How to recycle plastic to fuel oil with pyrolysis vessel?

To recycle plastic to fuel oil using a pyrolysis vessel, follow these steps: 1. Preparation of Plastic Material: Collect and sort the plastic waste, ensuring it is free from contaminants that may interfere with the pyrolysis process. Common plastic types suitable for this process include polyethylene (PE), polypropylene (PP), and Polystyrene (PS) , ABS plastic, aluminum plastic, medical waste, ...

-

How Biochar Production Can Ease Livestock Taxes

Biochar production is emerging as a transformative solution in agricultural management, particularly in addressing the environmental challenges associated with livestock farming. Through the use of advanced biochar making machines, farmers can mitigate emissions, improve soil quality, and unlock financial incentives, including tax relief. This article explores the connection between biochar ...

-

How is charcoal made?

Charcoal is made by heating biomass waste such as wood and fruit shells in an oxygen-deficient or low-oxygen environment. This process is called carbonization. The carbonization process removes moisture, volatile substances and other impurities from the wood, leaving behind a substance that is almost pure carbon, namely charcoal. There are many materials available for making charcoal, which can ...

-

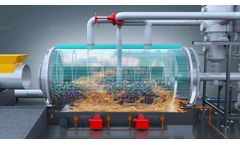

What is biomass continuous carbonization furnace?

The biomass continuous carbonization furnace is an efficient and environmentally friendly equipment for the thermochemical conversion of biomass resources. The whole set of continuous carbonization furnace converts biomass into charcoal by controlling the temperature, pressure and gas of the carbonized material. The whole set of processing technology of the continuous carbonization furnace ...

-

Operation Process of Biochar Production Equipment

The operation of biochar production equipment involves a series of meticulously controlled processes that transform organic biomass into a valuable byproduct. Biochar, a stable form of carbon, is created through the thermochemical conversion of organic materials in the absence of oxygen, commonly referred to as pyrolysis. This process not only reduces waste but also yields a product that has ...

-

What equipment can we select to set up a continuous pyrolysis machine project?

Setting up a continuous pyrolysis machine project involves a range of equipment and systems that work together to efficiently process waste materials (such as tires, plastics, rubber, medical waste, construction waste, e-waste, etc.) into useful by-products like fuel oil, carbon black, and syn-gas. Below is a comprehensive list of the equipment you will need to set up a continuous pyrolysis ...

-

The Role of Thermal Efficiency in Pyrolysis Reactor Performance

The thermal efficiency of a pyrolysis reactor is a critical factor in determining the overall performance, energy consumption, and economic feasibility of the pyrolysis process. Pyrolysis, a thermochemical decomposition process, is used to convert organic materials such as plastics, rubber, and biomass into valuable products like oil, gas, and charcoal. The efficiency with which the reactor ...

-

Can olive waste be used to produce charcoal?

Olives are mainly used to produce olive oil and table olives, and are a common economic plant. The global olive tree planting area exceeds 15 million hectares, of which about 80% are located in the Mediterranean region. Olives are the cornerstone of agricultural economy and sustainable development in these countries. In order to promote the growth of olive trees and produce more high-quality ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you