Pyrolysis Articles & Analysis

-

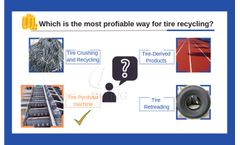

Waste tyre to oil pyrolysis plant

In today's era, dealing with waste tyres has emerged as a major concern both environmentally and economically. Conventional ways of tyre disposal like dumping in landfills or burning them not only cause serious harm to the environment but are also being gradually phased out because of strict environmental regulations. A highly potential solution is the waste tyre to oil pyrolysis plant. This ...

-

What are the advantages of waste to fuel pyrolysis machine?

In today's world, managing waste effectively is crucial for environmental sustainability. Waste to fuel pyrolysis machines have emerged as a innovative solution, transforming waste materials into useful fuel. This article explores the key advantages of these machines. Environmental Benefits: Traditional waste disposal methods, such as landfilling and incineration, often lead to pollution. ...

-

Puget Sound Energy, Modern Hydrogen Forge Decarbonization Path with Innovative Hydrogen Technology

Puget Sound Energy (PSE), Washington’s largest utility, and Modern Hydrogen, a clean energy technology leader, this week announced a strategic partnership to drive the adoption of advanced decarbonized technologies in support of meeting Washington state’s clean energy goals.Modern Hydrogen’s innovative carbon removal technology enables large-scale CO2 emissions reduction in Washington's most ...

-

DOING Oil Sludge Pyrolysis Plant for sale

Introduction of Oil Sludge Pyrolysis plant Oil sludge pyrolysis this advanced technology transforms waste oil sludge into valuable resources: fuel oil, solid residue through a process known as pyrolysis, which involves the thermal decomposition of organic materials in a controlled oxygen-free environment. How Oil Sludge Pyrolysis plant Works The core of this plant is a pyrolysis reactor, which ...

-

How to set up a waste tire to fuel oil pyrolysis machine project?

Setting up a waste tire to fuel oil pyrolysis machine project involves several key steps to ensure its success, from initial planning to operational execution. Here is a comprehensive guide written by DOING to help you through the process. 1. Feasibility Study and Market Research Conduct a thorough feasibility study to assess the potential of the project. This includes understanding the demand ...

-

Why continuous waste recycling pyrolysis plant is more popular than the batch type now?

Continuous waste recycling pyrolysis plants are gaining popularity over batch-type waste recycling pyrolysis plants for several reasons. Here’s a comprehensive look at why continuous systems are preferred in many applications: 1. **Higher Efficiency and Throughput** - **Constant Operation**: Continuous waste recycling pyrolysis plants can operate 24/7, processing feedstock without the need ...

-

Difference between pyrolysis and combustion

Pyrolysis and combustion are both processes that involve the decomposition of materials through heat, but they are fundamentally different in terms of the presence of oxygen, the chemical reactions involved, and the products produced. Here’s a breakdown of the key differences: 1. Presence of Oxygen - Pyrolysis: This is a process that occurs in the absence of oxygen or in very low-oxygen ...

-

How to ensure the environmental protection for the pyrolysis system operation?

It is becoming increasingly evident that pyrolysis systems hold immense potential in transforming waste materials like tires, plastics, and medical products into valuable commodities such as fuel oil, carbon black, coal, and syngas, thereby yielding substantial benefits. Investors eyeing the waste pyrolysis industry often harbor concerns about potential pollution and adherence to environmental ...

-

DOING three sets of semi-continuous tire pyrolysis units shipped to Brazil

Congratulations! On October 10, 2024, after meticulous packaging and loading, three sets of 15TPD semi-continuous tire pyrolysis units were successfully dispatched to Brazil. The Brazilian customer, who has been in the waste tire pyrolysis industry for years, recognized the need to upgrade his equipment due to technological advancements and the wear and tear on his existing units. In search of ...

-

What's tire pyrolysis oil(TPO)? What are the applications of tire pyrolysis oil?

The tire pyrolysis oil(TPO) extracted from waste tires through the pyrolysis process is tire oil. Due to the special properties of tire rubber, fuel oil extracted from waste tires usually presents the characteristics of heavy oil. Heavy oil, also known as fuel oil, is a petroleum product with high viscosity, high boiling point and high calorific value. Compared with light oil(such as gasoline and ...

-

What is the price of a 100 kg plastic pyrolysis system?

The price of a 100 kg plastic pyrolysis system can vary widely based on several factors, including the manufacturer, location, technology used, and additional features like emission control systems. On average, you might expect prices to range from $12,000 to $30,000 or more. 1. Overall technology: the plastic pyrolysis system we now have utilized will influence its price. Pyrolysis equipment ...

-

Pyrolysis Protest in Swansea

Tyregen UK Ltd has plans for an 8,000tpa pyrolysis plant in Swansea. In an outrage so typical when pyrolysis is mentioned, local objections to the plan have been piling up. Gowerton councillor Susan Jones said people had contacted her about the proposed installation and that “all are against”. Swansea council is considering a permit application from the company, but permission is ...

-

Gravita Eyes Romanian Pyrolysis Plant

Gravita India has announced that its subsidiary of company Gravita Netherlands BV (GNBV) has executed a Memorandum of Understanding to acquire a tyre recycling plant in Romania The acquisition will be done by forming a separate SPV in Romania in which GNBV will hold 80 per cent of the equity with management control and remaining equity being held by other partners based in Romania. The plant is ...

-

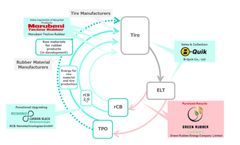

Marubeni Invests in Thailand Recycling Company

Green Rubber Energy has seen the Japanese investors take a 32 per cent share in the business. The investment is estimated at 1 billion yen ($7 million). Marubeni understands Green Rubber Energy’s pyrolysis technology will attract tyre manufacturers seeking to cut carbon emissions over their entire product life cycle. This is a further indication of a sea-change in the market that has, for ...

-

Bridgestone, Grupo BB&G and Versalis Develop Pyrolysis System

The agreement will bring together the innovation, experience and technological skills of all three companies. The partnership aims to develop a model for the creation of a scalable and increasingly sustainable supply chain. Around one billion tyres reach the end of their useful service life every year, according to the World Business Council for Sustainable Development (WBCSD)’s Tire ...

-

Malaysian Pyrolysis Pollution Problem on Sungai Pahang

The illegal factory is believed to have been extracting oil and wire steel cords resulting in air pollution due to the unregulated process using brick kilns, according to The New Straits Times. Justice arrived when the Department of Environment (DoE) and Pekan Municipal Council inspected the premises and ordered the plant to be shut down. Tanjung Cempaka Village Development and Security Committee ...

-

BTG Bioliquids completes basic design study for pilot pyrolysis fractionation plant.

The process of fractionation of fast pyrolysis bio-oil (FPBO), opens new pathways for the decarbonization of industries depending on fossil-based feedstocks with high greenhouse gas (GHG) emissions. Using a polar solvent in our liquid-to-liquid fractionation technology, we are able to produce stable fractions of pyrolytic lignin, pyrolytic sugars, light phenolics and wood vinegar. Together with ...

-

Leading Pyrolysis Plant Manufacturer and Supplier – Henan DOING Company

Henan DOING Company stands at the forefront of the waste to fuel recycling machine production field, renowned globally for over 14 years of expertise. Our commitment to innovation and quality has solidified our position as a leader in the industry. Here are the key advantages of choosing DOING Company for your pyrolysis plant needs: Advanced Pyrolysis Technology At Henan DOING Company, our ...

-

Top rated pyrolysis plant manufacturer and supplier-Henan Doing Company

China-Henan DOING is a top-rated pyrolysis plant manufacturer in waste to fuel recycling machine production field. We are specialized in waste to energy field for more than 14+ years. And we have strong strength in this field. See what our advantages are. 1. Henan Doing Company Possesses Mature and the Latest Pyrolysis Technology Henan Doing Company possesses advanced pyrolysis technology because ...

-

Different types of pyrolysis plants for sale from China manufacturer Henan Doing Company

When considering the operational modes, pyrolysis plants can primarily be categorized into three distinct types: batch, semi-continuous, and fully continuous. Each type has its unique characteristics and applications, catering to a variety of industrial needs and waste management scenarios. They are all available from China top pyrolysis plant manufacturer Henan Doing Company. DOING Brand ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you