Fuel Cell Components Equipment Supplied In USA

-

Manufactured by IRD Fuel Cells A/Sbased in DENMARK

The IRD Fuel Cells production plant is both suitable for customised prototype manufacturing for customers who require pre-commercial volumes, as well as for reliable supply of components within a large scale manufacturing ...

-

Distributed by Fuel Cell Storebased in USA

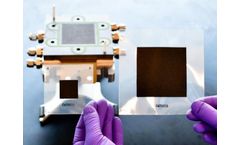

Membrane Electrode Assembly (MEA) for use in Hydrogen/Air Fuel Cells. One of the most economical and cost effective MEAs on the market, the standard configuration features a Platinum loading (0.5 mg/cm²) on a 0.002” membrane. This MEA can be purchased with or without a 410 micron thick woven carbon cloth GDL. Custom sizes and configurations are also available with no minimum order ...

-

Manufactured by Ionomr Innovations, Inc.based in CANADA

Ionomr offers pre-built membrane electrode assemblies (MEAs) in three standard sizes – 5, 25, and 50 cm² active areas – comprising Pemion® membranes coated with standardized catalyst layers as a convenient assessment tool for evaluation and integration of its proton exchange membrane ...

-

Manufactured by Fuel Cells Etcbased in USA

A low-cost electrode utilizing a woven carbon cloth substrate and a 20% Platinum on Vulcan Carbon support catalyst. This low loading is designed for cost sensitive applications and is suitable for electrochemical systems needing low amounts of Platinum to support the reaction. This electrode is perfect for Hydrogen/Air Fuel Cell applications where the extra cost of the higher loading GDE may ...

-

Manufactured by Fuel Cells Etcbased in USA

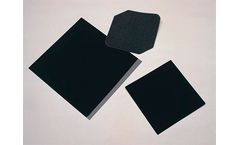

GDL-CT is a woven carbon cloth with a Microporous Layer (MPL). It has a total thickness of 410 um (microns). GDL-CT is a great low-cost alternative to conventional woven carbon cloth Gas Diffusion Layer (GDL) materials. Advantages of GDL-CT Stable MPL slurry with sophisticated coating technology High compressibility (up to 100kg/cm²) Automated QC inspection system Reduce catalyst slurry ...

-

Manufactured by Fuel Cells Etcbased in USA

Freudenberg H2415 - I2 C3 is a flexible and easy to use carbon paper Gas Diffusion Layer (GDL) with a Microporous Layer (MPL) as well as a hydrophobic treatment. It is recommended for low humidity systems, open cathode designs and air systems. It is 290 um thick. Freudenberg I2 C3 is recommended for: Power densities up to 0.5mA/cm2 Low humidified ...

-

Manufactured by Fuel Cells Etcbased in USA

Newly re-released at a fraction of the previous cost. NuVant's ELAT™ is a carbon cloth gas diffusion layer (GDL) with a carbon microporous layer. ELAT has been engineered to have state-of-the-art performance over a wide range of operating conditions. Thickness is 454 um. Gas Diffusion Layers (GDL) are key components of the membrane electrode assembly of the polymer electrolyte membrane fuel ...

-

Manufactured by Fuel Cells Etcbased in USA

The 4.0mg/cm² Platinum Ruthenium on Carbon Paper is the most popular Gas Diffusion Electrode (GDE) for use in Direct Methanol Fuel Cells (DMFC). The Platinum Ruthenium (PtRu) catalyst is designed to facilitate the Methanol reaction to create an efficient DMFC. The Gas Diffusion Layer (GDL) used is Sigracet 22 BB which is 215 microns thick. Other GDL materials are also available by custom ...

-

by AMOGY Inc.based in USA

At Amogy, we are building a novel portable carbon-free energy system using ammonia as a renewable fuel. Our system has 5x higher system-level energy densities compared to lithium batteries. This new energy system will enable the decarbonization of commercial transportation, where the existing and emerging technologies have critical limitations due to their low energy densities. ...

-

Distributed by Fuel Cell Storebased in USA

Anode and Cathode Gas Diffusion Electrodes (GDE) for an electrochemical device consist of catalyst loaded onto a gas diffusion layer (GDL). The mostly commonly used catalysts include carbon supported Platinum and Platinum/Ruthenium for the best catalyst dispersion and utilization for PEM Fuel Cells. Electrodes for a fuel cell applications are generally hydrophobic to reduce flooding issue ...

-

Distributed by Fuel Cell Storebased in USA

Dispersions (also called ionomers) are one of the critical components of fuel cell components. Catalyst layers require improved ionic conductivity for their optimal operation and hence, preparation of catalyst slurries with the correct dispersion materials will enable high performances. Dispersion (or ionomers) also act as binder agents such as securing the catalyst particles either on the ...

-

based in GERMANY

Modular test systems for fuel cell technology: With test systems, made by KRATZER AUTOMATION you will gain the benefit of having a solution which will allow you to carry out multiple tasks in the field of proving and testing of fuel cell technology for vehicle ...

-

Manufactured by Fuel Cell Technologies. Inc.based in USA

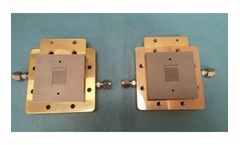

A Fuel Cell Hardware Assembly consists of a pair of Poco Graphite Blocks with a precision, machined flow-pattern (pattern is serpentine unless otherwise specified by the customer), and a pair of gold plated connectors fastened with aluminum end plates. Gas inputs and outputs are through Swagelok fittings. A thermocouple well and two cartridge heaters are also provided. A single Anode Reference ...

-

Manufactured by Fuel Cells Etcbased in USA

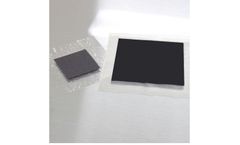

The 3-Layer MEAs, also known as Catalyst Coated Membranes (CCMs), do not come with a GDL. This will allow you to experiment with different GDLs to find more optimal structures in your testing environment. The downside is that the catalyst must now be applied directly to the membrane which is a more difficult process. Both options will perform equally after the break-in period for the MEA, which ...

-

Manufactured by Fuel Cells Etcbased in USA

A few key differences in the types of Membrane Electrode Assemblies, 7-Layer, 5-Layer or 3 -Layer, are the presence of gasket material, a pre-selected GDL, and the location of the applied catalyst layers. In the 5-Layer MEAs, the GDL is a standard carbon cloth with a microporous layer (MPL) applied to one side of the ...

-

Manufactured by Fuel Cells Etcbased in USA

The 2.0 mg/cm² Platinum Ruthenium on Carbon Cloth is the most popular Gas Diffusion Electrode (GDE) for use in Direct Methanol Fuel Cells (DMFC). The Platinum Ruthenium (PtRu) catalyst is designed to facilitate the Methanol reaction to create an efficient DMFC. The Gas Diffusion Layer (GDL) used is a standard carbon cloth with MPL which is 410 microns thick. Other GDL materials are also ...

-

Manufactured by Fuel Cells Etcbased in USA

The 4.0 mg/cm² Platinum Ruthenium on Carbon Cloth is the most popular Gas Diffusion Electrode (GDE) for use in Direct Methanol Fuel Cells (DMFC). The Platinum Ruthenium (PtRu) catalyst is designed to facilitate the Methanol reaction to create an efficient DMFC. The Gas Diffusion Layer (GDL) used is a standard carbon cloth with MPL which is 410 microns thick. Other GDL materials are also ...

-

by Hyzonbased in USA

Hyzon specializes in producing sophisticated hydrogen fuel cells that both provide high power output and emission-free operation. Their technology leverages the chemical reaction between hydrogen and oxygen to generate electricity, emitting only water as a byproduct. Known for their compact design, Hyzon's most advanced model, the 200kW fuel cell system, is noted for its efficiency and reduced ...

-

Distributed by Fuel Cell Storebased in USA

The Fuel Cell Store proudly carries the largest selection of carbon based Gas Diffusion Layers (GDL) in the world! AvCarb, Sigracet, Freudenberg, ELAT, Panex and more. Choose from a large variety of carbon cloths, paper and felts to fit your specific application ...

-

Manufactured by PDC Machines Inc.based in USA

PDC Machines is the World’s Leading Hydrogen Gas Compressors Manufacturer for Hydrogen Refueling Stations. PDC specializes in providing complete solutions for alternative energy applications. We are the #1 supplier of gas compressors for automobiles, bus and material handling fueling market with nearly 350 compressor installations worldwide and counting. With decades of experience in ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you