Incineration Articles & Analysis: Older

-

Is Pyrolysis a Continuous Process?

Pyrolysis is a thermal decomposition process that breaks down organic materials, such as plastic, rubber, and biomass, in the absence of oxygen. This process has gained significant attention for its potential in waste management and resource recovery, offering an effective way to convert waste into valuable products like fuel, gas, and biochar. A key question that often arises is whether ...

-

An RDF Alternative Fuel Preparation System For A Cement Company in Sichuan Province is on stable operation!

In October 2024, A cement company in Sichuan province adopted a Harden RDF alternative preparation system with advanced and multiple solid waste processing technologies, to achieve the continuous and steady operation of RDF alternative fuels processing for cement kiln. As a traditional high energy-consuming industry, the cement industry’s fuel and power costs have accounted for more than ...

-

The Role of Thermal Efficiency in Pyrolysis Reactor Performance

The thermal efficiency of a pyrolysis reactor is a critical factor in determining the overall performance, energy consumption, and economic feasibility of the pyrolysis process. Pyrolysis, a thermochemical decomposition process, is used to convert organic materials such as plastics, rubber, and biomass into valuable products like oil, gas, and charcoal. The efficiency with which the reactor ...

-

An RDF Alternative Fuel Preparation Project in Anhui, China is Successfully Put Into Operation!

In mid-October 2024, at the site of a ceramics factory with convenient transportation in Anhui Province, China, an RDF alternative fuel production line with an annual capacity of approximately 100,000 tons was successfully put into operation. It is a “green factory” for recycling local solid waste and is also the first Harden RDF alternative fuel preparation system in the region ...

-

Cement companies with RDF alternative fuel preparation system will seize the opportunity!

Mainstream carbon reduction methods In the cement clinker production process, industrial process emissions account for about 60%-65%, mainly carbon dioxide emissions produced by the decomposition of carbonates. Emissions from energy activities account for about 35%-40%, mainly carbon dioxide emissions produced during the combustion of fossil fuels such as coal. And the indirect ...

-

Carbon Dioxide Sampling - Why, Where, and When? Part 2: ETS Exemptions and Costs

In the introductory part of this short blog series (click here to read >>), we took a general look at the European emissions trading system ETS. However, it gets a bit more complicated than this through a variety of exemptions but played correctly, it also gives an opportunity to reduce the number of required emission permits and thereby also the associated costs. Exemptions There are many ...

By OPSIS AB

-

Project - Engineering for HVC’s ‘geothermal plants’

Situation Most people know HVC as a waste-to-energy plant or waste company. However, the fact that HVC is also active in generating renewable energy from green gas, solar parks and geothermal energy is much less known. In the Westland region, the soil is extremely suitable for utilising geothermal energy, or geothermal heat. HVC is now working on its third geothermal plant in this region, ...

-

What raw materials are suitable for DOING charcoal making machine?

Charcoal making machines have gained significant popularity in recent years due to their ability to convert various organic waste materials into valuable and eco-friendly charcoal products. These charcoal making machines utilize a process known as pyrolysis, which involves heating the raw materials in the absence of oxygen to break them down into charcoal and other byproducts such as wood ...

-

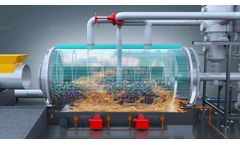

DOING waste to fuel pyrolysis machine solution customization

Many countries, like the United States, Malaysia, China, Russia, Italy, Japan, Thailand, Vietnam, Mexico, Colombia, South Africa, Chile, Spain, Brazil, etc. are struggling to manage their waste, especially plastic, tyre, oil sludge, plastic medical waste, solid waste, etc. The increasing amount of waste produced every day is a challenge for the government to dispose of it properly. DOING waste to ...

-

Fluidized Bed Incinerator - Modern Asia Environmental Holdings / Bang Poo / Thailand - Case Study

Contractor: Employment contract. Learning experience: Plant upgrade, operations. Customer / Operator: Modern Asia. Environmental Holdings / WMS. Project location: Bang Poo / Thailand. Industry: Waste Management. Waste types: Hazardous chemical/industrial ...

-

Counter-Current Rotary Kiln Incinerator - TES Group / Samut Prakarn 1 / Thailand - Case Study

Contractor: Dutch Incinerators TH. Contract type: EPC – Turnkey supply. Customer / Operator: TES Group – Thailand. Project location: Samut Prakarn 1 / ...

-

Counter-Current Rotary Kiln Incinerator - TES Group / Yala 1 / Thailand - Case Study

Contractor: Dutch Incinerators TH. Contract type: EPC – Turnkey supply. Customer / Operator: TES Group – Thailand. Project location: Yala 1 / ...

-

Counter-Current Rotary Kiln Incinerator - TES Group / Udon Thani 1 / Thailand - Case Study

Contractor: Dutch Incinerators TH. Contract type: EPC – Turnkey supply. Customer / Operator: TES Group – Thailand. Project location: Udon Thani 1 / Thailand. Industry: Medical Waste Treatment Center. Waste types: Medical, bio-medical & infectious clinical ...

-

Co-Current Rotary Kiln Incinerator - Modern Asia Environmental Holdings / Singapore - Case Study

Contractor: Employment contract. Learning experience: Plant upgrade, operations. Customer / Operator: Modern Asia. Environmental Holdings / Technochem. Project location: ...

-

Counter-Current Rotary Kiln Incinerator - TES Group / Rayong 1 / Thailand - Case Study

Contractor: Dutch Incinerators TH. Contract type: EPC – Turnkey supply. Customer / Operator: TES Group – Thailand. Project location: Rayong 1 / ...

-

Fluidized Bed Incinerator Rebuild - ECO-INC1 / Singapore - Case Study

Contractor: Dutch Incinerators NL. Contract type: EPC, Project Management. Customer / Operator: ECO – SWM. Project location: Singapore. Industry: Solid Waste Management. Waste types: Hazardous chemical ...

-

Investment Scenario for a Mini Pyrolysis Plant

The mini pyrolysis plant represents a significant opportunity for investors looking to enter the waste-to-energy sector. By converting waste materials such as plastics, tires, and biomass into valuable by-products, mini pyrolysis plants offer a sustainable solution to waste management while generating potential revenue streams. Understanding the investment scenario for a mini pyrolysis plant ...

-

RTO Regenerative Incinerator - Case Study

Regenerative Thermal Oxidizer (RTO) uses the ceramic regenerators to store the heat generated by the decomposition of VOCs, and uses the thermal energy stored in the ceramic regenerator to pre-heat and decompose the untreated VOCs, thereby achieving high thermal efficiency. The oxidation temperature is generally between 800 ° C and 850 ° C, up to 1100 ° C. Regenerative Thermal ...

-

VOCs Treatment RTO Incinerator - Case Study

Regenerative Thermal Oxidizer (RTO) uses the ceramic regenerators to store the heat generated by the decomposition of VOCs, and uses the thermal energy stored in the ceramic regenerator to pre-heat and decompose the untreated VOCs, thereby achieving high thermal efficiency. The oxidation temperature is generally between 800 ° C and 850 ° C, up to 1100 ° C. Regenerative Thermal ...

-

Alternative Fuel Production Solutions: Plastic Pyrolysis

The pursuit of sustainable energy sources has intensified as the world grapples with the dual challenges of waste management and energy security. Plastic pyrolysis, a method of converting plastic waste into valuable fuels, has emerged as a significant alternative fuel production solution. This process addresses both environmental and energy concerns by transforming plastic waste into usable ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you