Rotary Kiln Articles & Analysis

-

Beginning of cooperation with Ferrexpo Poltava Mining PJSC on natural gas substitution

Recently private enterprise Almaz-M has signed with Ferrexpo Poltava Mining PJSC the contract for the replacement of natural gas. Our company develops the project of building the Complex to replace the natural gas by solid biofuels, which in the future will save the Plant the consumption of natural gas. The work will be carried out on two rotary kilns for firing of pellets. ...

By Almaz-M

-

Environmental impact of incineration Fetching definition… of calorific industrial waste in a rotary kiln and in a cement kiln

A scientific study (Vermeulen et al., 2009) compared the environmental impact of incineration of high to medium calorific waste in a specialised waste incinerator (usually a rotary kiln) with incineration in a cement ...

By Eurits

-

Advantage by energy efficiency

When you speak of energy efficiency in thermal soil remediation, you cannot get past the VacuDry – technology. econ industries’ VacuDry technology has an energy efficiency of more than 80%. Concretely, 80% of the energy of the source fuel is transferred to the soil as thermal energy. A highly efficient boiler/burner unit ensures an exceptionally effective heat transfer from the ...

-

Dutch Incinerators Celebrates 6 Months of Successful Incinerator Operation

Six months of successful operations were celebrated today since the startup of a rotary kiln based medical waste incinerator in Thailand. After 3 months of operation the plant was inspected in January and since then the incinerator has been in continuous operation ever since, for more than 3 months uninterrupted operation. Dutch Incinerators designs are characterized by the focus on ...

-

Why Choose a Rotary Incinerator?

Although, the majority of machines that we manufacture are fixed chamber incinerators. There are occasions when considering a Rotary incinerator could be the right decision for you and your waste requirements. As every need is unique we would always recommend that if you have any questions that you let us help guide you to the best solution for you. Rotary Incinerators The main different in ...

-

Calciner firing of refuse derived fuels

Alternative or refuse derived fuels (RDF) are mainly fired in kiln burners, preheater or calciner kilns. Of the greatest importance in this regard is homogenous fuel quality consisting of two-dimensional parts. Alternative fuel for the kiln burner has to be free of disruptive fractions (e.g. metals, stones, glass), which might cause problems in the feeding equipment or the burner itself. ...

-

Refractory Insulation Bricks with Thermal Energy Saving Effect

Refractory insulation bricks, the unsung heroes of the construction and industrial realm, hold the key to thermal excellence and heat management. In an arena where extreme temperatures reign supreme, these bricks emerge as indispensable, providing critical thermal insulation. Let us explore the world of refractory insulation bricks, their significance, applications, and why they should occupy the ...

-

State-of-the-Art SRF Production Facility in Germany: Solid Recovered Fuels for an Entire Cement Plant 365 Days a Year

The two major players in recycling and waste processing: Lindner-Recyclingtech and the B+T Group have been partners for many years, successfully working together on many important projects. Now they are delighted to announce their latest project: a brand-new SRF production facility with the most modern technology in the whole of Germany. Developed and operated by the B+T Group, the facility is ...

-

What Kind of Environmental Kiln Needs Refractory Brick?

Refractory bricks stand as indispensable components within a multitude of high-temperature industrial kilns and furnaces. These kilns serve diverse purposes, ranging from ceramics and glass manufacturing to metals and chemicals processing. Within this article, we shall delve into the types of environmental kilns that necessitate the use of refractory bricks, shedding light on the significance of ...

-

How to Choose a Coconut Shell Charcoal Making Machine

As the demand for coconut shell charcoal continues to rise, choosing the right charcoal making machine becomes crucial for businesses involved in charcoal production. The quality and efficiency of the machine directly impact the final product, affecting both profitability and customer satisfaction. In this article, we will explore the key factors to consider when selecting a coconut shell ...

-

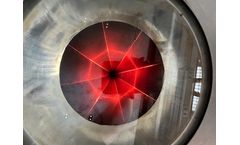

Cemex and Synhelion make further progress toward the world’s first fully solar-powered cement plant

Cemex and Synhelion announced today a significant milestone in their joint effort to develop fully solar-driven cement production: the scaling of their technology to industrially-viable levels. This includes the continuous production of clinker, the most energy-intensive part of cement manufacturing, using only solar heat. At the beginning of 2022, the companies announced the first-ever ...

By Synhelion SA

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you