Active Magnetic Bearing System

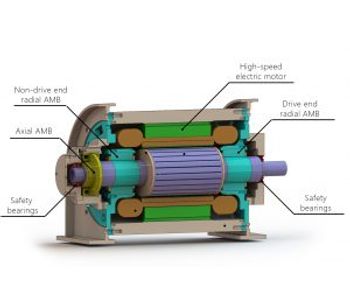

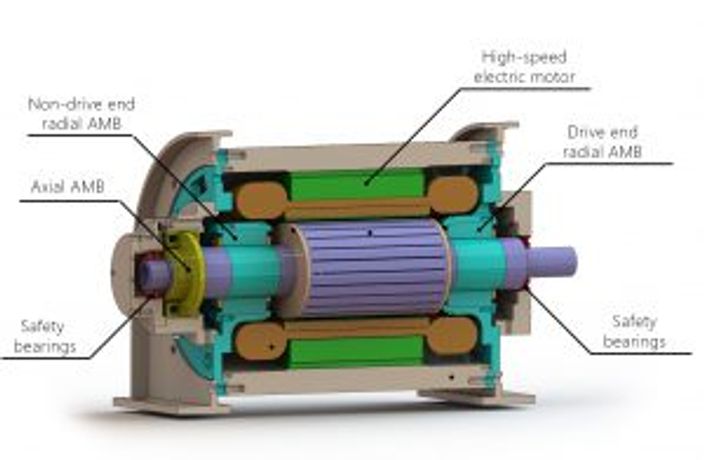

Magnetic bearings levitate the rotating part of the electrical machine with no contact. The system includes magnetic bearing controller, sensors and actuators. The magnetic bearing sensors monitor the position of the shaft and sends position information to the magnetic bearing controller. The controller drives the actuators, which keep the shaft at the center point.

Overview

Active magnetic bearing (AMB) is a type of contactless and frictionless bearing. It uses actively controlled magnetic forces to achieve levitation. By levitating the rotor there is no contact between the rotating and stationary parts.

Active magnetic bearings working principle

The suspended rotor is magnetically levitated and its position is monitored and controlled by the AMB system. The electromagnetic field generated by the AMB system is used to support the rotor, while the control system monitors and adjusts the force exerted by the electromagnets to ensure that the rotor is held in a stable position. This enables fast, precise rotation with minimal friction, energy losses, and wear.

Great potential for industrial applications

Industrial electric motors are the largest electrical end-users, accounting for approximately 45% of global electricity consumption. The existing high-speed electric motor solutions are inefficient and costly to maintain. Electricity and maintenance costs represent more than 70% of their total lifecycle costs. Active magnetic bearings (AMBs) are the solution to solve this problem. Industrial electric motors operate at high speeds (above 10,000 rpm). Hence, they are often subject to failures and breakdowns, which then compromise the productivity and efficiency of the entire system they drive. Our mission is to provide frictionless active magnetic bearings for high-speed electric motors. Thus, reducing electric motor system failures, maintenance, and electricity cost.

High-speed electric motors with magnetic bearings are getting increasing attention in the different industrial sectors. The motivation for their deployment varies considerably: the need to improve efficiency, and, thereby, to conserve energy and reduce environmental pollution, increase power density, enhance functionality, and improve reliability and maintainability are some of the key driving factors. Yet, in the context of new and more demanding industrial applications, ranging from distributed power generation to energy storage, to electric vehicles and industrial manufacturing processes, high-speed motors are still facing a wide range of challenges.

Benefits of Active Magnetic Bearing System

Principle of active magnetic bearings

Active magnetic bearings (AMBs) levitate the rotational part of the electric motor using electromagnetic forces. By levitating the rotor there is no metal-to-metal contact between the rotating and stationary parts. This significantly increases energy efficiency and reduces the maintenance costs of high-speed motors. The need for high shaft speed is one of the factors that call for magnetic bearing over more traditional bearing types.

The magnetic bearing system is levitating the rotational part of the machine. Levitation allows low-maintenance operation. Built-in sensors are ready for condition monitoring and enable predictive maintenance. Magnetic bearing technology helps customers to significantly increase their solutions’ system efficiency, reduce material consumption and minimize maintenance costs. Customer’s equipment lifecycle costs are reduced by 35% with the magnetic bearing solution.

Higher system efficiency

The need to increase the energy efficiency of the industrial processes is growing due to both economic and environmental reasons. About 70% of the lifetime costs of industrial equipment come from electricity bills and maintenance costs. These costs are directly affecting end-users profitability.

In a number of industrial applications, high rotational speed increases overall process efficiency, provides reduced energy consumption and smaller size machinery. Other related benefits are easier transportation, installation and reduced material consumption. However, with higher rotational speeds friction losses are significantly growing. To eliminate those the magnetic bearing levitation is applied, which reduces the power losses. Thus, magnetic bearing enables higher running speeds and higher efficiencies compared to conventional bearings.

Customer reviews

No reviews were found for Active Magnetic Bearing System. Be the first to review!