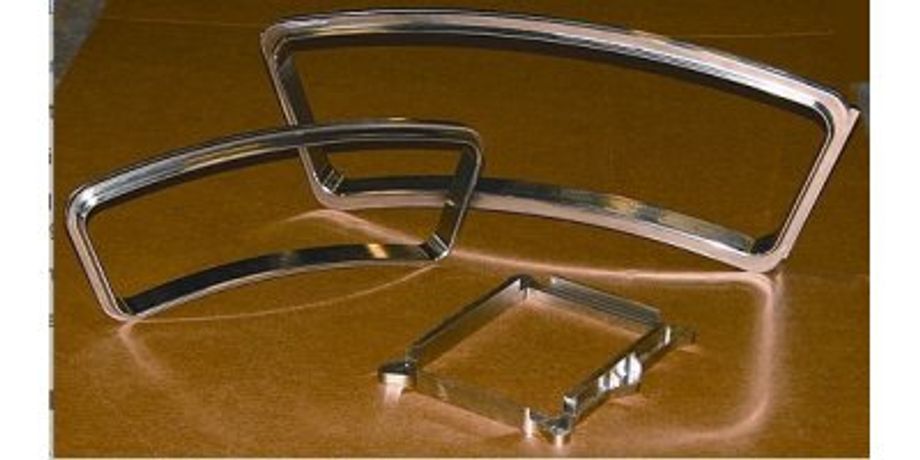

Aerospace - Custom Fabricated Gas Turbine & Heat Exchanger Frames

Making use of our abrasive waterjet cutting services and our milling expertise, Aerospace Alloys manufactures custom gas turbine and heat exchanger frames, designed for power generation and HVAC systems in an aircraft. We manufacture our turbine and heat exchanger frames from a choice of materials: Alloy-X, C263, and Alloy 625, and can work with material between 7/8” and 2” thick. Once we acquire the base material, we use abrasive waterjet cutting for blanks, and then a milling machining process to achieve the finished part.

-

Most popular related searches

Depending upon customer specifications, we can man...

Depending upon customer specifications, we can manufacture turbine frames and heat exchanger frames in dimensions up to 28” x 16”, with a finished weight typically between 20 and 50 lbs. We are able to achieve a finished surface roughness as smooth as RMS 32, and can produce prototypes prior to production runs in order to inspect the integrity of the piece. We serve aerospace industry customers nationally, with delivery times from 6 – 8 weeks.

Specifications

- Capabilities Applied/Processes: Acquired material, cut blanks with waterjet, milled to print, heat treated and coated.

- Tightest Tolerance: +/-.005'

- Material Thickness: From 7/8' - 2' thick

- Product Length: Longest 28'

- Product Width: Widest 16'

- Product Height: 7/8-2' thick

- Product Weight: Aprox: 20-50 lbs

- Surface Roughness: RMS 32

- Cutting Method: Abrasive water jet cutting and vertical milling.

- Base Material: Alloy-X, C263 and Alloy 625

- Industry for Use: Land Based Power Generation and HVAC in aircraft.

- Volume: Prototype to production quantities

- Delivery Time: 6-8 weeks

- Delivery Location: Nationally

- Product Name: Frames

- Drawing Type Accepted: .dwg and .dxf

Customer reviews

No reviews were found for Aerospace - Custom Fabricated Gas Turbine & Heat Exchanger Frames. Be the first to review!