Armaton - Multiaxial Fabrics

From Glass-Fiber Fabrics and Nonwovens

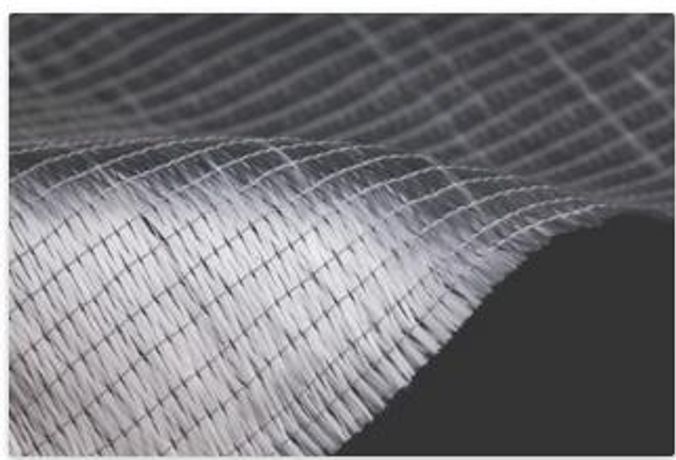

ARMATON multiaxial fabric is a textile material consisting of one or more layers of glass fibers. The layers are oriented in various directions and stitched with a polyester yarn. ARMATON multiaxial fabrics are manufactured using state-of-the-art equipment from Germany, which guarantees output of high-quality products.

-

Most popular related searches

Depending on number of layers, the following fabri...

Depending on number of layers, the following fabrics are manufactured:

-

One-layered /monoaxial (0/90)

-

Two-layered / biaxial (0/90), (+45/-45)

-

Three-layered / triaxial (0/+45/-45)

-

Four-layered / quadri-axial (0/+45/90/-45)

Application

Typical application:

ARMATON multiaxial fabrics are used as a reinforcing filler for making high-endurance materials out of fiberglass reinforced plastics (FRP).

The FRP based on multiaxial fabrics are successfully applied in the following industries:

- wind energy (blades, aerodynamic tunnel of wind power generators)

- aircraft (fuselages of planes and helicopters, main and anti-torque rotors of helicopters, wings, aerodynamic fairing, passenger seats)

- space (aerials, paraboloidal mirrors, autoclaves)

- marine (hulls)

- automotive (non-load bearing parts of a car body, refrigerated containers)

- railway (bodies of rail and subway cars, aerodynamic fairings, load-bearing parts of interior furnishing)

- building (reinforcement of concrete structures, window and door profiles, tents, bridges)

- tubes and vessels for storage and transportation of deleterious substances

- sports gear (tennis rackets, skis, surfs boards and snowboards, boats, bicycle frames, ice hockey sticks and helmets)

- medicine (medical devices)

Advantages

glass-fiber multiaxial fabrics are non-inflammable, non-toxic.

Compared to woven roving glass fabrics, multiaxial fabrics ensure:

- high strength properties in terms of tension, bend, torsion

- impact resistance

- quick and high-quality impregnation with binding agent

- reduction in quantity of fabric during laying and optimization of composites manufacturing process

- high workability

- possible reinforcement of composite materials in different directions

- reduction in consumption of resin to 20-30%: owing to non-interwowen yarns, strands are laid denser as compared to roving fabrics, thus resulting in lower resistance to flow of a binding agent

- final weight may be reduced to 50%

- mechanical strength may be increased twice (twice mechanical strength of roving fabrics with comparable surface weight)

- strict adherence to assigned reinforcement design

- absence of nodes on surface of product.