Baolan - Model DeSOx - Desulfurization Equipment

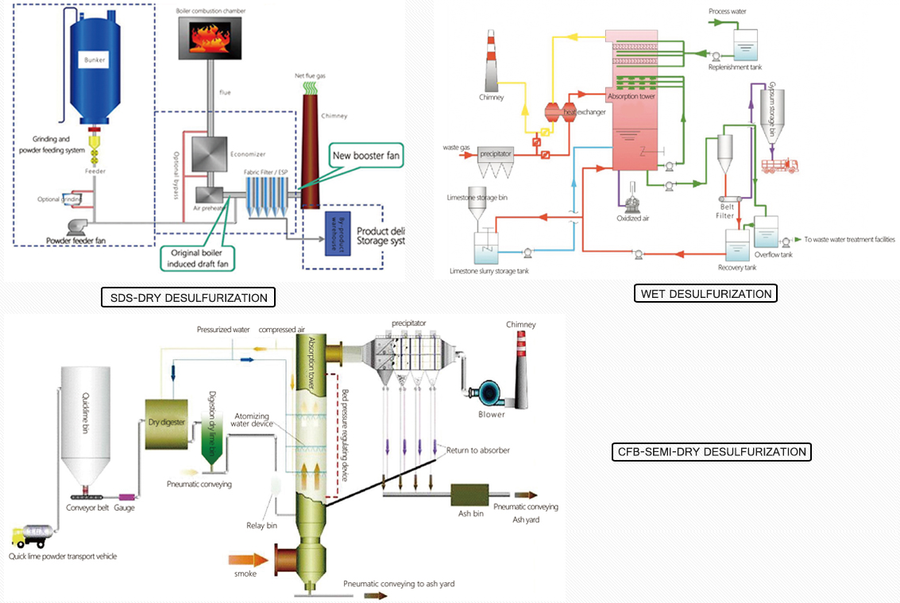

Dry desulfurization is to utilize the reducibility and flammability of SO2, using solid oxidant or adsorbent to desulfurize, or directly make it burn. Dry desulfurization is a method to produce Na2SO4 by the reaction of NaHCO3 and SO2, which is called dry desulfurization.

Device Types

CFB(Semi-Dry Desulfurization)

Semi dry desulfurization technology is a simple, low investment, high performance desulfurization system, covering a small area, easy to access. The process is mainly used in power plant boiler flue gas desulfurization. The flue gas treatment capacity of single tower can be applied to boilers with evaporation capacity of 75t / H ~ 1025t / h, and the SO2 removal rate can reach 90% ~ 98%. It is a method with the largest single tower treatment capacity and the most superior comprehensive desulfurization benefits among the dry and semi dry desulfurization technologies.

WET Desulfurization

Lime / gypsum desulfurization process is a kind of wet desulfurization, which uses limestone, lime or dolomite as desulfurization absorbent to remove SO2 in waste gas. Limestone is widely used and is one of the earliest sorbents for flue gas desulfurization. It is the most widely used and most mature standard desulfurization technology in the world.

Service

- complete the project tasks according to the customer's requirements to ensure the project quality;

- the waste gas treatment device designed and provided by the company shall meet the local standards and national standards after treatment by the facility;

- guarantee the main equipment, provide technical services for the whole life, reply in time in case of any problems during the operation of the equipment, and arrange professional personnel to provide on-site services within 24 hours;

- when the warranty period expires, our company will only charge a certain cost for equipment maintenance and repair. Establish long-term contact and technical exchange with users, provide users with the latest technology and free technical consultation and service;

- during the commissioning of waste gas treatment system, and be responsible for training technical personnel. Including daily operation management, equipment operation procedures, common troubleshooting, regular maintenance of equipment, etc;

- regularly organize customer return visits, understand the system operation status, carefully handle customer feedback, and do a good job in engineering and technical consultation.

Customer reviews

No reviews were found for Baolan - Model DeSOx - Desulfurization Equipment. Be the first to review!