ECC - Refinery Heaters

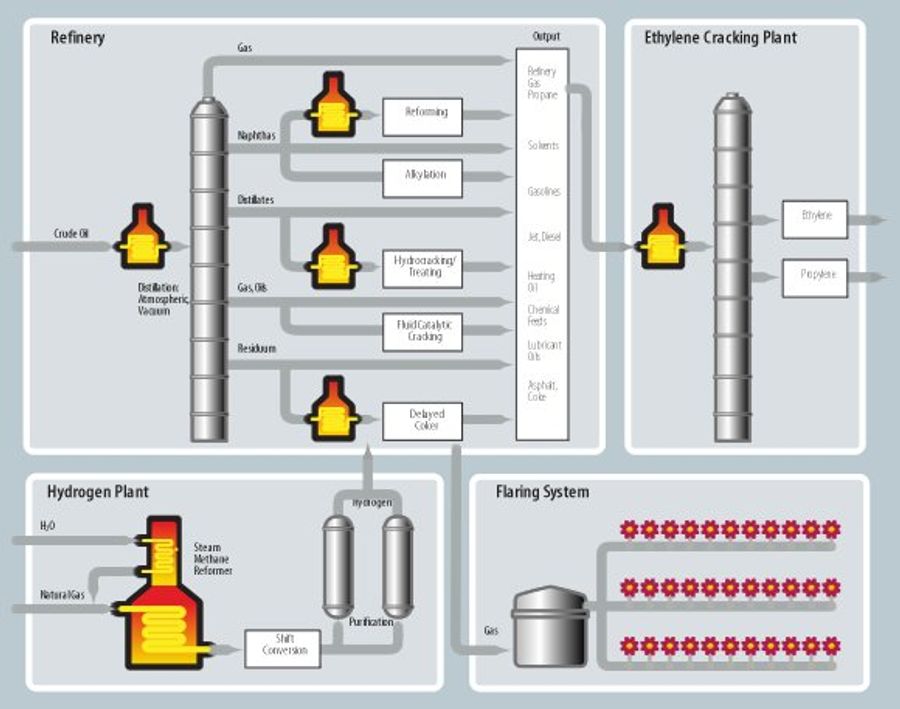

Because they are at the front end of the most processes in refineries and petrochemical processing facilities, optimal functioning of heaters is essential to ensure adequate production. Heater designs come in a variety of configurations depending on the process and engineering company supplying them. A common configuration is the vertical-cylindrical, up-fired system, employing multiple burners, which are installed on the furnace floor in a circular pattern. The design of these heaters must meet American Petroleum Institute guidelines which stipulate flame length must not exceed 2/3 the height of the furnace.

-

Most popular related searches

The Problem

The Problem

The introduction of Low and Ultra-Low-NOx burners, which incorporate fuel staging and delayed mixing in their designs, increases flame length and reduces momentum (sometimes referred to as ‘lazy’ flames), potentially exceeding these API guidelines. These lazy flames mean multiple flames can coalesce into a large ball of fire in the center of the combustor (as opposed to several discrete flames), which causes impingement on the convection section of the furnace. This leads to coking, which can reduce throughput and damage process tubes. This ‘ball of fire’ also causes NOx levels to increase.

The ECC Solution

ClearSign ECC technology promises to reduce flame length while maintaining discrete, individual flames with the desired momentum. Impingement on process tubes would be reduced, preventing undesirable coking inside the tubes and promoting longer tube life. The combination of controlling oxygen in the stack (reducing from 3% O2 to 1% O2) while improving overall thermal transfer in the radiant section would also yield significant energy savings. Further, NOx levels would be maintained to within regulatory requirements. Operators would enjoy economic benefits including increased capacity and throughput, increased system uptime, and reduced maintenance expense.

Debottlenecking Capacity

Some heaters retrofitted with Low and Ultra-Low NOx burners are being pushed beyond their design capacity and experience flame impingement on the convection section tubes. This forces operators to cut back on capacity. It is suggested that a capacity increase of the order of 3-7% could be achieved by reducing flame height with the use of ECC.

Customer reviews

No reviews were found for ECC - Refinery Heaters. Be the first to review!