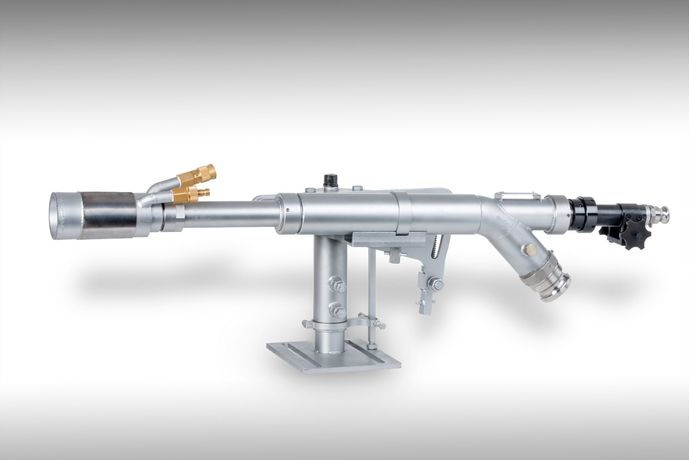

FlammaTec - Model FreeJet - Gas Injector-Type Burner

From Burners / Injectors - Gaseous Fuels

FT FreeJet gas injector-type burner creates extremely low gas impulse that slows down the combustion process and increases soot formation. It leads to optimal heat transfer from combustion to the glass melt, improved furnace efficiency, maximum pull and extremely low emission when replacing conventional burners.

-

Most popular related searches

Technical Data

TECHNICAL SPECS

fuel

natural gas, LPG, LNG, propane

energy output

0.2 – 8.5 MW (3 sizes)

purge air

≥ 0.1 bar (non-?ring period)

water cooling

10 – 20 l/min (continuous)

CAPABILITIES

applicable under-port ?ring for regenerative cross-?red and end-port furnaces

injection of the fuel into the furnace following the opening angle of a free gas jet

adjustable gas velocity, vertical, and horizontal angle

injector positioned flush with inner side of furnace chamber

position requires water-cooled diffusor

Advantages & Benefits

- burner technology achieves low NOx emissions

- increased energy ef?ciency

- lower crown and waste gas temperatures

- lower speci?c energy consumption

- increased melting capacity

- decreased thermal corrosion of refractories leads to increased furnace lifetime

- low maintenance

- less burner block corrosion produces fewer defects

Scope of supply

- FT FreeJet gas injectors operating ± 30% of nominal capacity

- injector brackets

- stainless steel ?exible hoses

Options

- optimization of melting process using CFD simulation

- rental and maintenance contract

- port design optimization

- regular service during and after warranty period

- control panels & safety trains delivery

Customer reviews

No reviews were found for FlammaTec - Model FreeJet - Gas Injector-Type Burner. Be the first to review!