GAB-Neumann - Silicon Carbide Block Heat Exchangers

From Silicon Carbide Heat Exchangers

CORRESIC silicon carbide block heat exchangers are adapted to the heating, cooling, evaporation, condensation and absorption of highly corrosive and/or oxidizing chemicals. This design is one of the most versatile type of silicon carbide heat exchangers. Rows of holes are drilled through the silicon carbide blocks both horizontally and vertically to form the process and service channels. Heat is transferred by conduction through the silicon carbide left between the rows of holes which separate the mediums being used. SiC block heat exchangers consist in a stack of blocks encapsulated in a steel shell.

-

Most popular related searches

Product Details

Snapshots

Cold isostatic pressing of a silicon carbide block

Cold isostatic pressing is a powder compaction method conducted at room temperature and involving applying pressure from multiple directions through a liquid medium surrounding the compacted part. A flexible mold immersed in a pressurized liquid medium is used. The material used to manufacture silicon carbide blocks is produced by cold isostatic pressing.

Deep drilling of a silicon carbide block

After cold isostatic pressing the silicon carbide blocks are precisely machined and deep drilled with computer numerical controlled machines.

Deep drilling of a silicon carbide block

After cold isostatic pressing the silicon carbide blocks are precisely machined and deep drilled with computer numerical controlled machines.

Deep drilling of a silicon carbide block

After cold isostatic pressing the silicon carbide blocks are precisely machined and deep drilled with computer numerical controlled machines.

Sintering of silicon carbide parts in a vacuum furnace

After machining the silicon carbide blocks are sintered at high temperature in a vacuum furnace.

SE type silicon carbide block

Our SE SiC blocks are made of pressureless sintered SiC thus guarantying their outstanding corrosion resistance.

Numerous SE type Silicon carbide blocks

Numerous SE type SiC blocks before their assembly in a block heat exchanger.

SE type Silicon carbide block

Our largest SE SiC block seen from the side.

3D Renderings

SE 16, 26 and 35 silicon carbide blocks

GAB Neumann has developed SiC blocks with different drilling patterns and hole diameters on process and services sides to better adapt to customers’ specific requirements

SE 35 silicon carbide blocks

In order to best fit with customers’ process requirements GAB Neumann has developed different types and sizes of SiC blocks

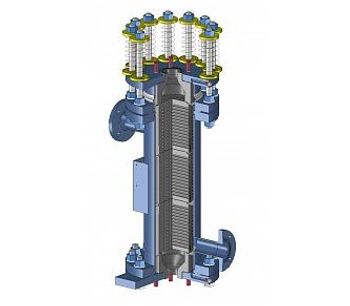

SE 16 SiC block heat exchanger with silicon carbide blocks and headers in a carbon steel shell

SE 16 type SiC block heat exchangers can be fitted with silicon carbide, PTFE lined steel or glass lined steel headers

SE 26 SiC block heat exchanger with 8 blocks

SE 26 type SiC block heat exchangers with silicon carbide headers.

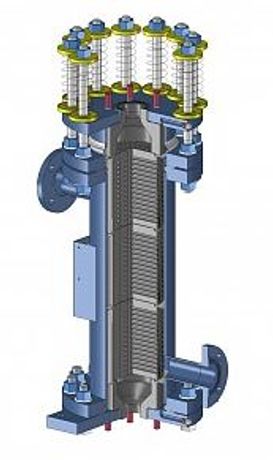

Cross section of a SE 26 SiC block heat exchanger with 8 blocks

Cross section of SE 26 type SiC block heat exchangers with silicon carbide headers.

Baffle arrangement

Baffle arrangement in a SE 26 block heat exchanger with 8 blocks.

- CORRESIC® pressureless sintered silicon carbide blocks and headers

- Shell, Pressure plates and flanges: carbon steel or stainless steel

- Tie rods, nuts, bolts, washers, springs: stainless steel

- PTFE gaskets between the blocks

- Totally modular design: number of blocks, size of blocks and number of passes can be adjusted

- Different drilling diameters on process and service sides

- Different block diameters: 160, 260 and 350 mm

- Silicon carbide, PTFE lined steel or glass lined steel headers on product side

- Thermal expansion compensation ensured by stainless steel expansion bellow on the shell

Features

Key Features:

- Design pressure: -1 barg (full vacuum) to +16 barg (230 psig)

- Design temperature: -60 to +220°C (-76 to 428°F)

- Heat transfer area: up to 22 m2 (238 ft2)

- Design: according to European PED, ASME code, Chinese Pressure Vessel code and other national pressure vessel codes on request

Optional features:

- Removable headers for easy mechanical cleaning

- Sight glass

Key Benefits

- Outstanding corrosion resistance against acid, bases and oxidizing media

- Good heat transfer performance thanks to adjustable cross sections on both sides

- Easy disassembly

- Ability to mechanically clean each block

- Second hardest material existing on earth thus eliminating any risk of erosion

- High operational safety

- Compact, sturdy and modular design

- Short lead time

- Long lifetime

Main Applications

- Cooling, condensation, heating, evaporation and absorption of ultra-corrosive and/or oxidizing chemicals or ultra-pure chemicals.

- Suited for multi-purpose or single purpose units

Customer reviews

No reviews were found for GAB-Neumann - Silicon Carbide Block Heat Exchangers. Be the first to review!