Greatwall - Lime Rotary Kiln

From Lime Kiln

As an experienced rotary kiln manufacturer, we offer rotary kilns for lime production lines. We can also design lime rotary kilns for lime calcination to meet your process need and materials, from testing to finished product. A rotary kiln for lime production is a high-temperature lime calcination kiln for processing limestone and other solid materials. Custom rotary kilns are available. Our highly-engineered rotary kilns have earned a reputation for durability, efficiency, and longevity. The rotary lime kiln is the main equipment for calcined active lime production.

-

Most popular related searches

Products Details

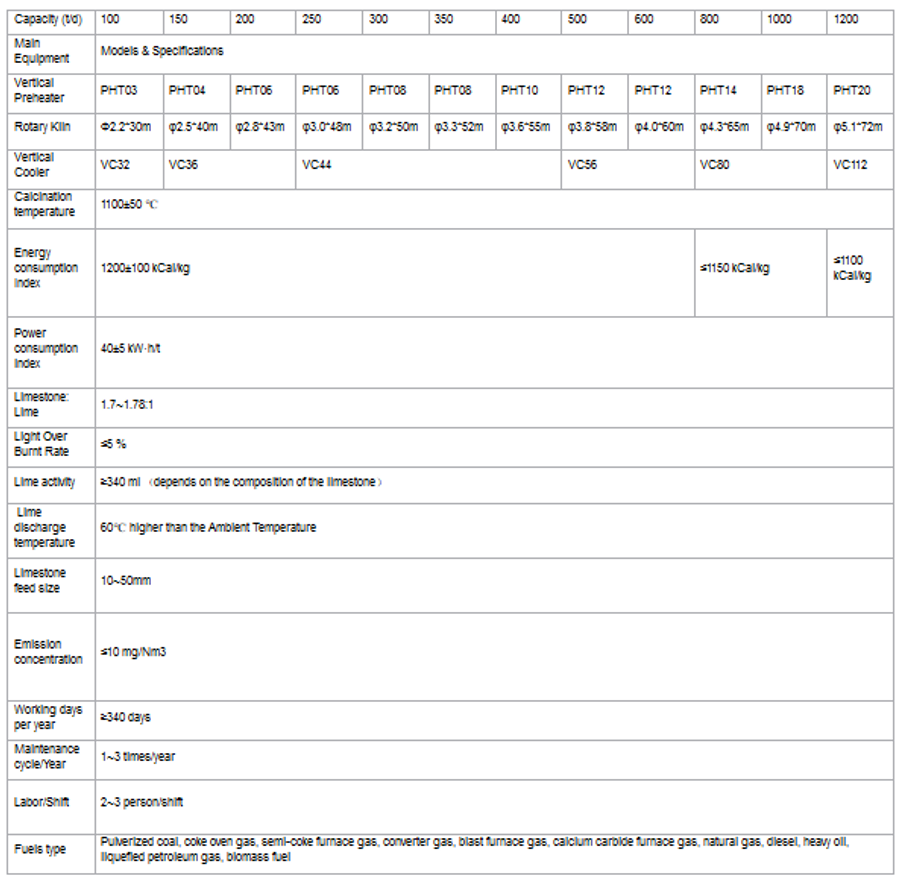

- Processing Capacity: 100-1200t/d

- Max. Feeding Size:10-50mm

- Application Fields: A Lime rotary kiln is suitable for calcining limestone in metallurgy, the chemical industry, and the building material products industry.

- Customized Service:Custom rotary kilns are available.

Advantages

The rotary lime kiln is a new type of special rotary kiln for active lime production. This type of rotary kiln can be equipped with a vertical preheater and vertical cooler to form an energy-saving rotary kiln calcination system.

- The vertical cooler at the kiln head can not only quench the high-temperature lime but also increase the activity of the product. The activity of lime is 30ml higher than that of lime made by the traditional shaft lime kiln.

- The output of the rotary kiln is stable, and suitable for large, medium, and small active lime production lines.

- The kiln body has a simple structure. Uniform heating, stable product quality, and the rate of light and burnt are low.

- High raw material utilization rate, uniform good quality, and large production capacity.

- Accommodates various fuel types. The rotary kilns can use pulverized coal, coke oven gas, semi-coke furnace gas, converter gas, blast furnace gas, calcium carbide furnace gas, natural gas, diesel, heavy oil, liquefied petroleum gas, biomass fuel, etc. as fuels.

Main Structures

The Lime rotary kiln is mainly composed of a supporting device, transmission device, sealing device, kiln head guard plate, kiln body, kiln tail, and so on.

Working Principle

- After being crushed by the jaw crusher, the limestone is fed into the kiln through the chute at the upper kiln tail. Due to the inclination and slow rotation of the cylinder, the limestone rolls along the circumference and moves axially from the upper kiln tail to the lower kiln head;

- At the kiln head (lower end), the fuel is sprayed into the kiln for combustion through the burner, and the heat is transferred to the limestone by radiation, convection, and conduction. After the limestone is calcined into quicklime during the movement, it is discharged from the kiln head.

- The high-temperature smoke enters the dust removal system at the kiln tail.