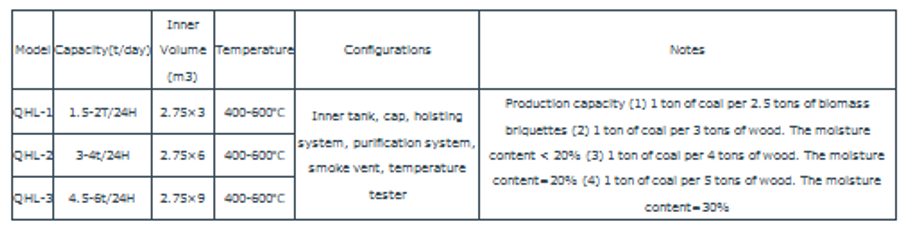

Guoxin - Model QHL-1 - Carbonization Furnace

From Charcoal Making Processing Equipment

The carbonization furnace is mainly used for drying and carbonizing different raw material, such as wood, wood log, coconut shell, bamboo, nut shell, briquette, hardwood, wood branch etc. Our company provides a comprehensive range of low-temperature, medium-temperature and high-temperature furnaces, which are featured by advanced technology, short circle, high production, environmental protection and long service life.

-

Most popular related searches

Products Details

- Model:QHL-1

- Capacity(t/day):1.5-2T/24H

- Inner Volume (m3):2.75×3

- Temperature:400-600?

Main Configurations

- Outer Stove

The diameter: 2100mm, the height: 2000mm. - Inner Stove

One set of carbonization furnace includes three inner stoves, respectively with a diameter of 1500mm, 1470mm and 1440mm. - Purification System

The function of purification system is to collect the dust and to purify gases produced by the carbonization furnace. When the carbonization stove works, it produces such combustible gases as methane, CO, etc. The gases go through the purification tank and come back to the bottom of carbonization stove for reuse. That's how the energy is recycled. As for wood tar and wood vinegar produced during the machine running, they are collected and discharged from the purification tank. - Hoisting System

By using a hoisting system, carbonized briquettes can be directly lifted from the furnace and cooled outside. Currently, 3-ton and 5-ton hoisting system are offered. - Temperature Detector

Every inner stove is matched with a temperature detector. The operator can check the temperature inside the stove anytime. - Cap

For good carbonization performance, each inner tank is covered with a cap. When the carbonization is finished, it's forbidden to open the cap since the coal will be oxidized and start igniting at once. The right thing to do is that lift the inner tank out of the furnace by the hoister and open the cap until the temperature decreases to 30?.

Features

- This carbonization system adopts destructive distillation technology and has three furnaces. Every inner tank is able to hold 1 tons of woods or 2 tons of briquettes. Three furnaces continuously work and vastly improve the production efficiency.

- In the destructive distillation process, byproducts will be separated by tar separator and fan, posing little harm to the environmental and realizing cycle use.

- Generally, wood, coal, natural gas and coconut shells are most often used as fuel. When the carbonization machine is stably working, combustible gas produced is sufficient for the normal machine operation. 1 m3 generates 300m3 combustible gas.

Customer reviews

No reviews were found for Guoxin - Model QHL-1 - Carbonization Furnace. Be the first to review!