Kaori - Brazed Plate Heat Exchanger

The brazed plate heat exchanger is engineered to optimize the transfer of thermal energy between two fluids with high efficiency. Known for its compact design, this type of heat exchanger excels in environments requiring stringent space constraints. It demonstrates significant resistance to corrosion and can endure high pressures, making it suitable for demanding industrial applications. Operating across a wide range of working temperatures, the brazed plate heat exchanger maintains reliable performance and efficiency. Its construction minimizes the need for maintenance, providing cost-effective operation over time. Ideal for HVAC applications, refrigeration systems, and various industrial processes, it integrates advanced materials and assembly techniques to ensure robust thermal management in diverse operational settings.

Product Details

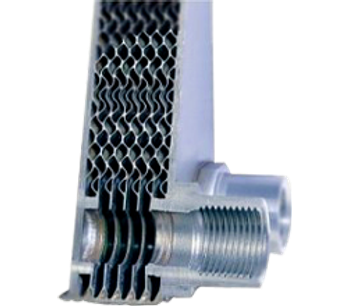

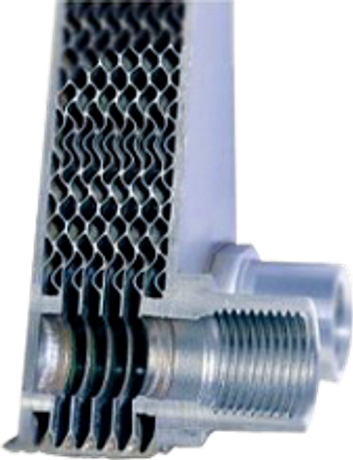

Kaori's brazed type heat exchanger consists of a series of thin and corrugated stainless steel plates. These plates are compressed and brazed together with copper or nickel depending on the application. This creates flowing channels between plates, with one fluid in odd number channels and the other in the even number channels, thus reaching the purpose of heat exchanging.

Different from the gasket seal type, brazing type uses soldering material (copper or nickel depending on the application) to seal the exchanger. By applying high temperatures in the vacuum environment at the manufacturing process, it melts down the soldering material to form the seal between each of the plates.

Advantages

- High corrosion resistant

All plates uses SUS316 material. Brazing materials come in copper or nickel versions. These materials offer high corrosion resistance against a variety of fluids. - High pressure resistant

Thanks to the brazing process, plate heat exchangers are pressure resistant up to 45 bar.* - High thermal efficiency

Carefully designed plate pattern of the corrugated plates easily achieves high thermal transfer rate in either counter flow or parallel flow arrangement. - High working temperature

Brazed Plate Heat Exchanger's SUS316 material structure offers higher working temperature range up to 200℃. - Compactness

Brazed Plate Heat Exchanger is much lighter in weight and smaller in size, if compared to shell tube exchangers; about 1/5 the size of the shell tube exchanger of the same capacity. This advantage makes Brazed Plate Heat Exchanger easier to install and replace. - Low maintenance

The corrugated plates are designed to achieve turbulence flow at a low flow rate, thus decreasing the need for frequent maintenance.

*Maximum value. may vary with products. Please refer to the tables for particular type of exchanger.

How BPHEs Work

Kaori's Brazed Plate Heat Exchangers (BPHE) are made by pressing a series of thin corrugated stainless steel together and brazed with copper or nickel. The soldering material is then melted in a vacuum furnace to form a seal between each of the plates. This brazing process seals the plates together making extremely durable and allows for Kaori BPHEs to perform under high working pressure and temperatures.

The spaces in between the plates become flow channels with one fluid flowing in odd number channels and the other in the even number channels. Heat exchange occurs through the designed plates over a large surface area making Kaori BPHEs very efficient. Nearly all of the material is used for heat transfer making it also very compact and cost-effective.

The spaces in between the plates become flow channels with one fluid flowing in odd number channels and the other in the even number channels. Heat exchange occurs through the designed plates over a large surface area making Kaori BPHEs very efficient. Nearly all of the material is used for heat transfer making it also very compact and cost-effective.

Plate patterns are designed for performance with respect to your application. Special consideration is given when designing the width of chevron angles and height of curvature of the individual plates. Plate patterns cause high turbulence flow which significantly reduces fouling and increases heat transfer performance. After decades of research and development, Kaori has optimized plate patterns for specific applications and continues to find innovative ways to increase performance while minimizing pressure drop.

Standard BPHE flow pattern is a single pass arrangement; meaning working fluid flows in a single direction through the unit. A multi-pass arrangement is where working fluid can change its flow path and is sometimes used for low flow rates or extremely close temperature approaches. Other times, multi-pass arrangements are used to provide flexible design configurations in certain applications.

While there are many things to consider when purchasing a new BPHE with regard to optimizing design and application, a Kaori representative can help you with selecting the most suitable heat transfer solution.

While there are many things to consider when purchasing a new BPHE with regard to optimizing design and application, a Kaori representative can help you with selecting the most suitable heat transfer solution.

Benefits

Kaori brazed plate heat exchangers are the most efficient, economical, and environmentally thermal solution for today’s industrial demands. The many advantages of Kaori BPHEs go hand in hand with its highly efficient thermal design.

High-quality Solutions

Kaori BPHEs are high thermal performance solutions capitalize on basic thermal principles and are brazed together with Kaori’s expertise in thermal technology. The rate of heat transfer increases with the amount of conductive surface area and can be further increased by the amount of fluid turbulence. We take advantage of this principle by brazing together thin high-quality plates thereby maximizing the surface area available for heat transfer.High turbulent flow to reduce fouling

Each corrugated plate is also designed to increase fluid turbulence. Its angle, pattern, and depth can all be optimized for performance with regard to specific working fluids. High turbulent flow promotes a scrubbing effect within the heat exchanger to reduce fouling and maintain its high performance.Efficient use of materials

Kaori BPHEs exhibit such high thermal performance that we can significantly reduce the size of the heat exchanger while still achieving target working temperatures. This mass reduction in size leads to all-around savings in material, space, shipping, installation, and refrigerant volumes. Kaori BPHEs are essentially highly conductive heat transfer surfaces stacked together so nearly all of its material is used for heat transfer. This not only means more efficient use of materials, but also leads to a huge reduction in materials needed to get the job done.Reduction of CO2 emissions

Thermal solutions that are smaller, lighter, more compact will give greater design flexibility for engineers and provides many environmental benefits as well. Its smaller size also reduces CO2 emissions from production, transportation, and requires less working fluid to operate.Kaori's long experience in manufacturing and expertise in thermal technology allows us to be flexible in customizing our heat exchangers to meet you where you are. Kaori’s BPHEs can be customized to handle a wide range of systems and capacities, and paired with the right connectors you need for easy installation.

Quality Assurance

Kaori is proud of its long standing tradition for manufacturing quality products. We select high grade quality materials to ensure finished products are durable and guarantee high thermal performance. Kaori implements a meticulous inspection process and traceable documentation occurs at every stage of production in order to exceed international standards of quality. In addition to testing 100% of all finished products for leakage before packaging, our products go through the following rigorous tests in order to maintain top quality standards.

- Life Cycle Testing

- Burst Testing

- Performance Testing

- Thermal Shock Testing

- Anti-Corrosion Testing

Customer reviews

No reviews were found for Kaori - Brazed Plate Heat Exchanger. Be the first to review!