Biodiesel Product Equipment & Supplies

-

Manufactured by Biodiesel Projectbased in CHINA

Our biodiesel technology program employs the low-temperature reaction of esterified and maximum extent possible to solve program. The process is one of the lowest energy consumption in the biodiesel process, taking gas esterification process, maximum extent possible to solve and mass transfer problems. ...

-

Manufactured by Henan Barui Environmental Protection Equipment Co..Ltd.based in CHINA

Estenfication & Trans-esterification unit, is used to generate fatty acid methyl ester (biodiesel) from used vegetable oil (raw mateiral oil). The unit developed by us, consits of 2 types: reactor (see IMG 1) or reacting tower (see IMG 2). Besides, there is our own developed organic acid esterification process, that is the most advanced all over the ...

-

Manufactured by Ceimici Novelbased in IRELAND

SmartCat™ delivers fast and complete transesterification as part of a continuous production process. Stage 1 at 60-62°C with 0.5% SmartCat™ for 2 hours producing 90% biodiesel and methanol. Stage 2 at 60-62°C with 35% SmartCat™ yields 100% biodiesel with trace catalyst and ...

-

Manufactured by ecoMotion GmbHbased in GERMANY

Another attractive feature of biodiesel production is the range of valuable by-products. These are used in a variety of sectors, including food, cosmetics, oleochemicals, fertilisers and energy production. ...

-

Manufactured by Springboard Biodiesel LLCbased in USA

Springboard Biodiesel’s closed local loop biodiesel production system, called the CLL-1000 (CLL) is designed as a zero-waste, integrated, automated, multi-modular processing system. It allows an operator to produce the highest quality biodiesel from the lowest priced, regionally sourced feedstock. ...

-

Manufactured by World Energybased in CANADA

Traditional biodiesel production processes typically utilize feedstocks with Free Fatty Acid (“FFA”) content less than 1% because the presence of FFAs during the transesterification process will produce soaps and emulsions, which prevents the separation of methyl esters from glycerine. ...

-

Manufactured by Franken Filtertechnik KGbased in GERMANY

We have been supplying phase separators for many years to well-known plant manufacturers and producers in the fields of: Separation of biodiesel and glycerin after transesterification, Separation of finely dispersed washing water from biodiesel and – depending on the process - also for other liquid-liquid separation tasks. We engineer and manufacture ...

-

Distributed by Ayalytical Instruments, Incbased in USA

Eliminate BIAS in Silver Corrosion Ratings. Methods: ASTM D4814, ASTM D7671, IP 611. From qualified practitioner to quintessential professional, designed with the end user in mind. Sensors in modern automotive fuel systems often use silver or silver alloys, which are susceptible to corrosion from sulfur in gasoline. In the past decade, refiners have shifted to producing lower-sulfur gasoline, but ...

-

Manufactured by Biodiesel Projectbased in CHINA

he methanol recovery column, also called methanol distillation column, is mainly used for separating waste water and methanol during biodiesel production in order to recycle and obtain high purified methanol. This device is based on the needs of biodiesel production technology, combined the efficient structured stainless steel ...

-

Manufactured by Biofuel Systems Group Limitedbased in UNITED KINGDOM

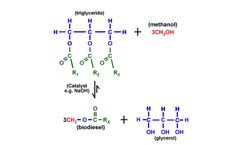

Biodiesel is produced via the transesterification of fats as shown by the chemical reaction to the left. There are some excellent publications relating to Biodiesel production. At Biofuel Systems we have been most impressed with the comprehensive Biodiesel Handbook and have made this available on our online ...

-

Manufactured by Ceimici Novelbased in IRELAND

Biodiesel production, in general, uses 100% excess of methanol* to ensure a complete and timely reaction to specification. Methanol recovery is essential to maximise process economies and meet international ...

-

Manufactured by CT Systemsbased in UKRAINE

Our company has developed new modules for biodiesel production BioSMART-CT based on new cavitation processors PULSAR-CT 730. Eleven types of the BioSMART-CT modules allow to process from 1 up to 16 cubic meters of oil per hour. Extremely precision system of initial products dosing based on Coriolis principle, new high-effective cavitation ...

-

Manufactured by UCO Trading Spain S.L.based in SPAIN

By-product of biodiesel production with glycerol content between 60 and 82%. It can be used by different industries: oleochemistry, biogas, animal ...

-

Manufactured by Apeiron AgroCommodities Pte Ltdbased in SINGAPORE

Our biodiesel products meet European EN 14214, American ASTM D-6751 and Indonesian SNI 04-7182 standards and specifications. Through our relationship with major chemical additives companies, we can arrange with our biodiesel suppliers to customize the products for specific customer needs in various geographical regions in the ...

-

Manufactured by CT Systemsbased in UKRAINE

PULSAR-CT cavitation reactors are the core elements of BIOTRON-CT automatic biodiesel production ...

-

Manufactured by GlobeCorebased in GERMANY

STRUCTURE AND PRINCIPLE OF COMPLEX OPERATION ON PRODUCTION OF BIODIESEL (biodiesel)The complex on production of the biodiesel consists of the following installations ...

-

Manufactured by Chevron Renewable Energy Groupbased in USA

A reliable solution for high-quality products. Chevron Renewable Energy Group Glycerin is a high-quality, consistent co-product from biodiesel production that Chevron Renewable Energy Group strategically markets domestically and internationally from a growing network of biorefineries. ...

-

Manufactured by ASB Biodieselbased in HONG KONG

Crude glycerin is one of the main by-products during the production of biodiesel. After the purification of crude glycerin, it can be produce food, soap, cosmetics and purified drugs of glycerol. Around 400-500 tons could be supply per month ...

-

Manufactured by Icon Scientific Limitedbased in UNITED KINGDOM

Designed to replace the traditional Engine based method, it works well with Diesel and Biodiesel products. It’s cheaper, faster and requires a lot less maintenance. It eliminates the drawbacks of the traditional CFR Engine, and the issues associated with model based chemometrics used in FTIR and Raman spectrometers. The measurement includes the effects of ...

-

Manufactured by Buyo India Pvt Ltdbased in INDIA

The chemical process of transesterification is employed in biodiesel production, transforming triglycerides into fatty acid methyl esters (FAME) and separating the biodiesel from by-products like glycerin. This fuel has a high gross calorific value, specific gravity, and viscosity, catering to both transportation and industrial ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you