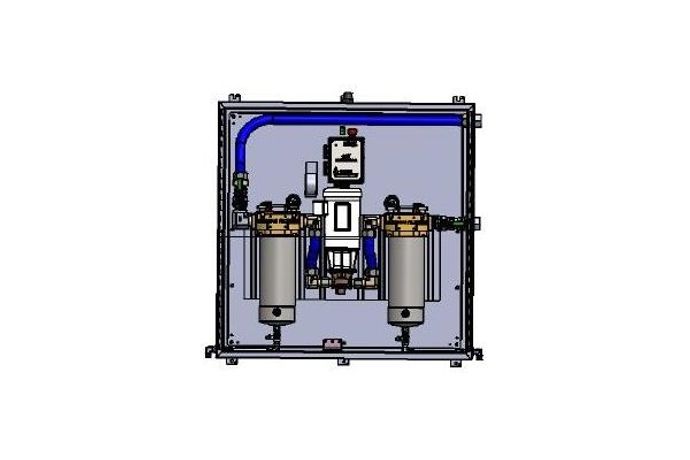

KTI - Model KW 1500GSM - Diesel Fuel Cleaning System

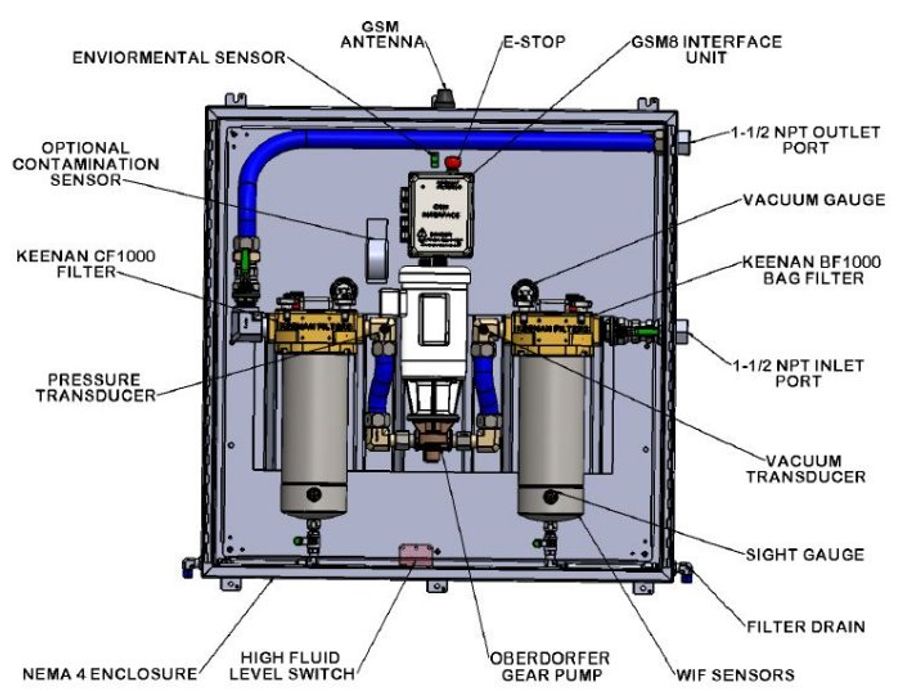

The KW 1500GSM was designed to meet the tough diesel fuel cleanliness requirements of todays engine manufacturers. This system utilizes an industrial grade SCADA monitoring system incorporated into our interface controller. The combination of our highly efficient filters and interface allows the polishing system to remove contaminants, sludge and water to meet SAE and ISO fuel requirements.

-

Most popular related searches

Features

- SCADA remote control/monitoring

- Operate over any IP network

- Fully programable

- Highly efficient filtration

- Easy and clean element replacement

- Oberdorfer continuous duty pump

- Optional “Contamination Sensor”

- Keenan Top loading filters housings

- NEMA 4 or 4X enclosure

The interface controller allows for detailed on-si...

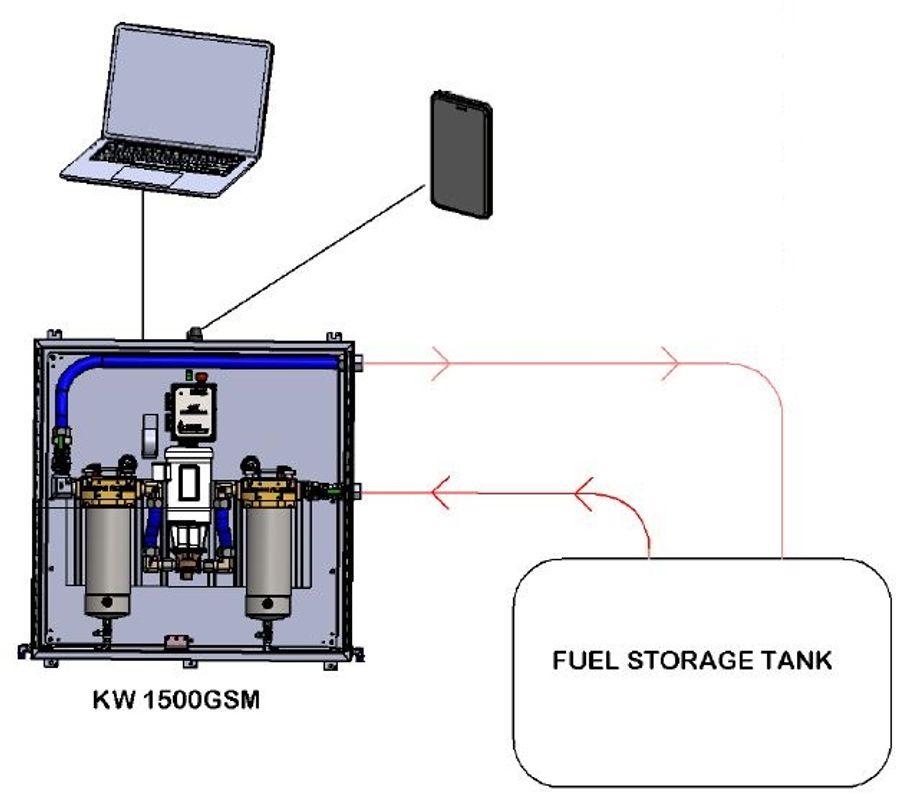

The interface controller allows for detailed on-site monitoring, control and alarm notifications using GSM or internet to your smart phone or laptop. When the system is in polishing mode the operator can monitor fuel flow (optional), filter condition, water detection, fuel leaks and the pump operation. If any of the preset alarm settings are reached the system will automatically notify the operator that a problem is present and if severe, it will shut the system down. A wide variety of measurements can be polled to ensure proper operation.

The optional “ Contamination Sensor” integrated into our system will now allow the operator to polish (clean) to a desired ISO code, once met the system will shutdown or it can switch to another storage tank.

Fuel filtration starts at the prefilter to remove large contaminants, sludge and water before entering the pump. Next the prefiltered fuel enters and highly efficient 3 stage coalescing filter that allows a limitless amount of water removal while also removing 99.5% particles smaller the 4 micron.

This filter element uses synthetic filter media eliminating degradation due to high water fuel content and has almost 2X the amount of filtration surface than the original design. Our patent pending top loading design allows for efficient and clean filter servicing.

Technical Specifications

- Flow rate: 25 GPM (1500 GPH) 5678 LPH

- Pump: Oberdorfer 1.5 hp gear pump

- System Control: Keenan Filters GSM 8 interface

- Ports: 1-1/2” NPT

- F1 BF1000: #4 bag filter 1-100 micron

- F2 CF1000: 5 micron FBO type coalescer/particle filter

- Enclosure: NEMA 4

- Dimensions:

- 48”x 48” x 12”

- 122 x122 x 30 cm

- Weight: 300LBS 136 KG

- Power: 120 V 60HZ, 208-230 V 60 HZ, 230 V 50HZ 1 PH

Options

- Contamination Sensor

- Continuously measures solid contamina-tion ISO 9/8/7 to 25/24/23 range

- Enclosure material

- As required per environmental conditions

- Enclosure ventilation

- Temperature controlled fan system

- Enclosure heater

- Keeps interior at a constant temperature

- Fuel heater

- Reduces fuel from gelling

Replacement Elements

- BF1000: Element 1 to 100 Micron

- CF1000: Element 5,10 and 25 Micron

Customer reviews

No reviews were found for KTI - Model KW 1500GSM - Diesel Fuel Cleaning System. Be the first to review!