Model Biosonator - Biogas Plants

The BIOSONATOR is a complete system using high- performance ultrasound for increasing efficiency and energy generation in biogas plants. It was developed in 2011 within the scope of a ZIM (Central innovation program for small and medium–sized businesses) project. In the meantime, more than 100 plants, both at home and abroad, have been successfully equipped. The BIOSONATOR is the jointly developed work of a consortium with extensive experience in the field of biogas plant engineering. Together, the companies Ultrawaves (high-power ultrasound in water and environmental technologies), IGEA (plant planning & design), Kotlarek (piping of biogas plants) and Matzdorf (automation of processing plants) have successfully planned and equipped more than 100 plants in Germany and abroad up to now.

In 2011, the four companies consolidated their kno...

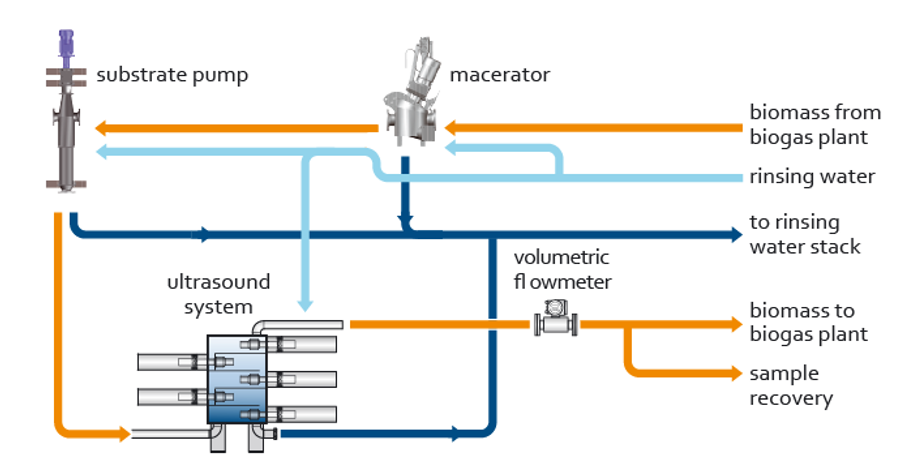

In 2011, the four companies consolidated their know-how for a ZIM project (Central Innovation Programme SME), to develop a complete system on the basis of ULTRAWAVES high-power ultrasound technology to increase the efficiency of biogas plants. They focused on the objective of designing a simple solution for operators, which can be directly integrated into the plant without requiring additional technology (plug & play). The result is a complete package of macerator, pump, ULTRAWAVES high-power ultrasound system and programmable logic controller (PLC), which is delivered ready for use in a compact standard 10‘ container – the BIOSONATOR.

Areas of use and advantages

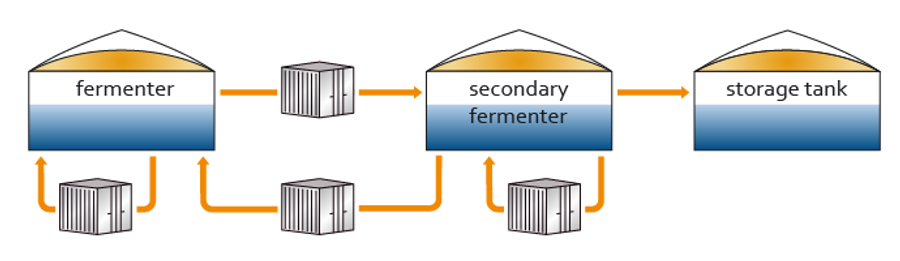

This innovative technology can be used to treat especially fibrous and rough biomass suspensions (grass, manure, etc.) which are generally difficult to digest. The operator therefore remains independent of readily fermentable substrates of high quality (e.g. maize). Preferably, a recirculation flow from the secondary fermenter in the main fermenter is processed with the BIOSONATOR.

The biomass is broken down and increased microbiol...

The biomass is broken down and increased microbiological activity in the fermenter is boosted. The consequence of the intensified process is significantly increased biogas production (usually 10 to 15 %), achieved with little energy input. The amortisation period of the investment is 3 to 5 years, therefore relatively short. The container is easy attachable to the biogas plant. Connections are available on the outside for the inlet and outlet of substrate and rinsing water. Only an electrical connection (400 V, 32 A, TN-S net) is required for its use.

Equipment and technical layout

Inside the BIOSONATOR there are four units, arranged in the technological sequence:

- Macerator unit with spur gear motor (2.2 kW drive output)

- Modified eccentric screw pump with spur gear motor (1.5 kW drive output) and frequency converter

- High-power ultrasound system (Ultrawaves/Sonotronic) with 5 kW connected load

- Volumetric flowmeter

The individual elements are connected with stainle...

The individual elements are connected with stainless steel pipes (DN 100 and DN 65). All valves and fittings have the same stainless steel quality.

The following parameters are recorded and processed inside the BIOSONATOR:

- Volumetric flow

- Temperature

- Pressure

- Ultrasound power in percent (output parameter of the ultrasound controller)

- Operating time

The automation is implemented with a SIMATIC S7-300 module made by Siemens. The plant flow diagram and the recorded readings are visualised on a multi-touchpanel. The BIOSONATOR‘s control system can be integrated in the biogas plant‘s control system via a data interface. The power supply, power circuits and the PLC are accommodated in a wall-mounted control cabinet.

Optimised operation - Increased plant efficiency

The BIOSONATOR can be optionally run in automatic (standard state) or manual mode. First, the eccentric screw pump draws the biosuspension through the macerator. Here any of the long fibrous solids are broken up to ensure stable pump operation. The Ultrawaves ultrasound system is located at the discharge end of the pump. Here, the pressure fluctuations caused by ultrasound produce enormous cavitation forces, which break up the biomass structure (disintegration). The biomass disintegration makes the substrate readily available, intensifies the digestion process and therefore more biogas will be produced.

Alternatively, the operator can maintain a constant biogas quantity and yet reduce the feed. In addition, an increase in methane content improves the quality of the biogas. The simultaneously induced lowering of the viscosity achieved by the use of ultrasound also produces savings in the plant‘s own power consumption.

A time-controlled rinsing system is integrated to maintain a stable and safe operation of the BIOSONATOR. This ensures a long life for the ultrasound system. Due to permanent recording and monitoring of the main process-specific parameters the plant operator is always able to operate the BIOSONATOR optimally.

Operating Parameters

Volumetric flow: 10 to 33 l/min or 0.6 to 2 m3/h biomass suspension

Medium: Biomass suspension with approx. 5 up to 10% w/w dry solids

Medium temperature: 33 to 55°C

Operating pressure of the ultrasound system: max. 2.5 bar in ultrasound mode

Operating period per year: Continuous operation over 8,760 h/a less maintenance/ service

Customer reviews

No reviews were found for Model Biosonator - Biogas Plants. Be the first to review!