Modular Auto-Segmentation System

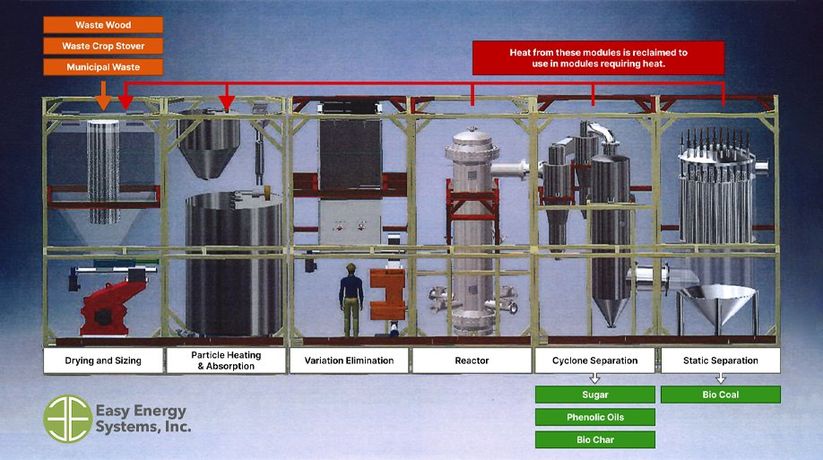

The Easy Energy Auto Segmentation System™ is a patented, self-contained, and fully automated processing system for converting agricultural biomass, waste wood, forest fire prone dead trees, municipal garbage into many different valued added products while also sequestering large amounts of CO2. All modules are pre-fabricated and tested in a factory. They can be shipped anywhere in the world in fully automatic, self-contained, shipping container-sized modules that can be quickly installed. They are designed for use in remote communities and villages with rural ag biomass or even in remote forest clearings such as clearing up forest fire prone dead trees.

Details

The system has the ability to convert forest waste bio-mass into distributed low or even negative carbon electricity for providing local or main grid electrical needs to help provide additional distributed electricity. This low to negative carbon electricity is an ideal solution for the increased need for clean electricity for charging electrical cars and trucks. As the smaller size factory built modular plants will typically be located world-wide in rural villages and communities, this will provide massive amounts of clean distributed electricity without the need or time delay of expensive additional transmission lines.

The base system has a 50 ton per day capacity, but can be scaled to process up to 250 dry tons of waste wood or other bio mass per day.

The auto-segmentation preprocessing portion will dry and grind the wood chips while converting them into liquid sugar and many other valuable products. Multiple “sets” of these 6 modular sections deployed in different sawmills or even remote forest clearings. These units will convert the waste (even partially burned forest fire wood) into a valuable condensed liquid sugar that can then be trucked or piped via a large flexible hose to remote access roads for transportation to a central site MEPS™ processing unit.

The MEPS™ will then convert sugars and starches into biofuels which can then be further converted into low carbon electricity. This central site will have the required fermentation tanks and distillation and other clean up modules needed to convert the incoming sugars and other products into where the sugars are then further converted into bio-fuels, aviation fuels, or electricity. It is estimated this one 250 ton per day final processing plant will provide up to 7.3 megawatts of clean renewable low-to-even carbon negative electricity.

Ability to be Operated With No Outside Utilities Required

Depending upon the cost or even total lack of outside utilities in remote rural villages or even remote mountain clearings, the systems can be configured to operate with NO incoming gas or electric utilities. Simply provide the system the incoming waste wood, dead trees, or biomass and the unit is capable of providing all of its own required electricity and heat energy. This is vastly different than most pyrolysis systems that claim to be renewable, but actually require massive amounts of incoming gas or electricity to operate their systems.

Superior to Conventional Biomass to Energy Systems

Most traditional biomass to energy systems are really just high priced “burning barrels” that simply burn the biomass to create heat and then the heat produces steam that powers a turbine to generate electricity. With these competitors, virtually all of the harmful gases, CO2, and other dangerous waste chemicals are discharged into the atmosphere causing pollution and local health concerns. The EES Auto Segmentation System™ instead creates virtually no pollution as it fully separates everything out into many value added products.

Customer reviews

No reviews were found for Modular Auto-Segmentation System. Be the first to review!