Solex - Moving Bed Heat Exchangers for Drying Bulk Solids

Unlike conventional drying and conditioning technologies which blow hot air through the product as both the heat source and the way of removing moisture; Solex uses a combination of advanced plate heat exchange technology to provide the heat source and independent sweep air to remove the moisture. This approach greatly reduces air-flow requirements, returning much better efficiencies and improved process control.

Products Details

Our technology heats bulk solids indirectly through conduction, significantly increasing the moisture-carrying capacity of the sweep air for precise temperature and moisture control.

Waste heat can be used to power the process, reducing costs and energy consumption even further.

How it Works:

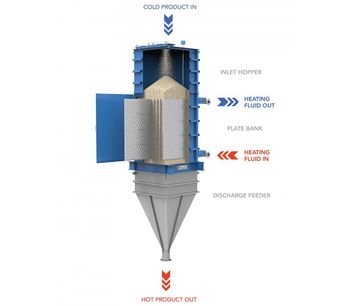

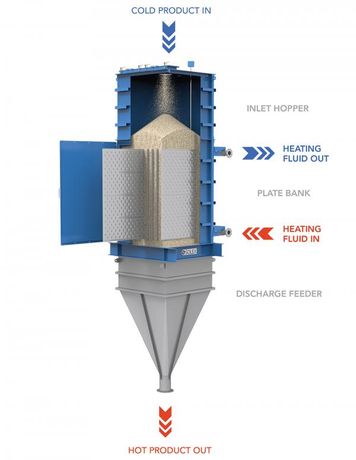

Controlled product flow

Free-flowing bulk solids pass slowly downward between a series of vertical hollow heat exchanger plates.

Indirect heating

Hot water, steam (or waste heat) flow through the plates to heat the material and evaporate moisture from the product.

Sweep air

Sweep air removes product moisture. A small amount of sweep air is used to remove moisture from the product.

Save up to 90% More Energy

Solex bulk solids drying and conditioning technology enables both moisture content and the temperature of the final product to be independently and precisely controlled.

Because the temperature of sweep air is controlled and does not drop, the air maintains its moisture carrying capacity and is capable of carrying larger quantities of moisture.

As a result, only a very small amount of sweep air is needed to remove moisture from the product, improving efficiency by 90% or greater.

Reuse Recovered Waste Heat

Because the product is heated indirectly, waste heat from elsewhere in your facility can be used as a heat source – without the need for air scrubbing equipment.

When waste heat is used, the dryer operates with minimal new energy consumption - operating nearly for free.

Reduce Maintenance & Installation Costs

Reduce operational footprint

The bulk solids drying and conditioning unit’s modular, vertically orientated design takes up less space and uses no moving parts, requiring far less maintenance over time.

Stay operational through maintenance

Plates are individually connected using flexible hoses, allowing for thermal expansion and enabling you to remove plates individually for repair, replacement and cleaning without long-term operational delays.

Scale quickly

The drying and conditioning unit’s modular design can be quickly expanded should your capacity requirements increase.

Our bulk solids drying solutions will increase your efficiency, decrease your costs and improve your end product – guaranteed.Work with a partner who’ll be there every step of the way.From initial consultation and commissioning to ongoing support, we offer services to help you get the most out of your operations at every stage of the product’s life cycle.

Specifications

Suitable applications

- Ideal for grains and oilseeds

Capacity:

- 100 kg/hr to 100,000 kg/hr

Customer reviews

No reviews were found for Solex - Moving Bed Heat Exchangers for Drying Bulk Solids. Be the first to review!