Spilling - Steam Turbine

From the single-stage, overhung turbine to the efficiency-optimised multi-stage, tandem type turbo set – Spilling steam turbines are suited to the most varied customer requirements and applications. The wide-ranging product line is geared to the decentral generation of energy and enables a wide range of applications in driving power ranges between 300 to 5,000 kW. At the focus are applications that use process heat or regionally available fuels and waste heat sources to generate steam. Spilling steam turbines can be also designed with bleeding and controlled extractions.

They are ideally suited for use as a

They are ideally suited for use as a

- back pressure turbine

for integration in the steam and heat supply in CHP plants for industry and district heating networks - condensing turbine

to generate electricity from recycling materials and waste heat - back pressure turbine with bleeding

to supply different consumers in CHP applications - condensing turbine with bleeding / extraction

to simultaneously supply heat consumers and optimise the conversion of excess heat into electricity.

Product Line:

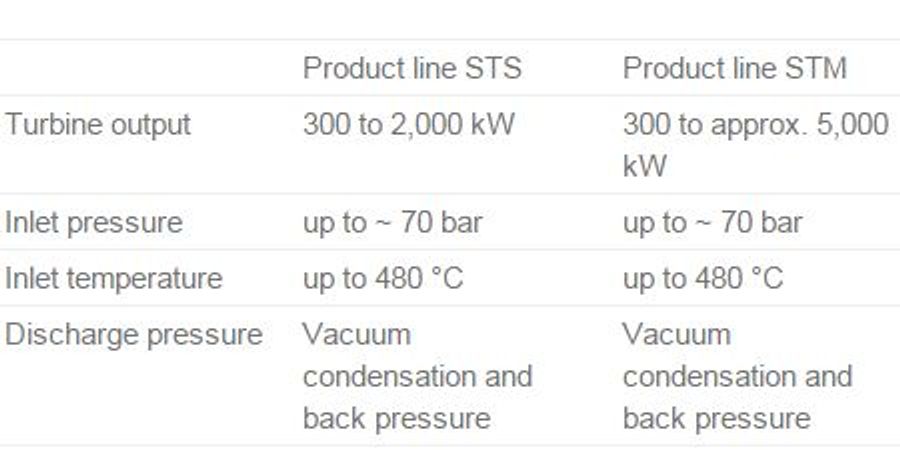

- STS – single-stage steam turbine with overhung design with integrated gear unit for simple assembly, simple operating and low operating costs.

- STM – single to seven-stage impulse turbine, tandem type also with up to 10 stages. Suitable for applications where high efficiency and generating larger outputs are paramount. The concept of this product line permits individual adjustment of pressure staging and so efficiency is optimised for the respective operating conditions.

Your Benefits:

- Select the suitable turbine type from a wide range

- Individual solutions with customised scope of supplies and service

- Cost optimisation on all levels

An Overview of the Construction Features

STM steam turbine

- Power output: up to approx. 5,000 kW

- Design: axial turbine

- Mode of operation: impulse principle

- Turbine version with dual bearing system horizontally divided turbine housing

- Modular turbine housing configuration

- Project-specific dimensioning of turbine staging

- Drive: generator or work machine (pump etc.)

- Version with throttle valve or nozzle group control

- Set-up as tandem unit in different combinations also possible

STS steam turbine

- Power output: up to approx. 2,000 kW

- Design: axial turbine

- Mode of operation: impulse principle

- Overhung design with integrated gear unit

- Standardised turbine housing

- Project-specific dimensioning of nozzles and impellers

- Drive: generator or work machine (pump etc.)

- Version with throttle valve or nozzle group control

- Set-up as tandem unit also possible

Services and Accessories

The range of services provided by Spilling goes far beyond delivering your steam turbine and also includes

- water-cooled vacuum condensers

- heat exchangers to extract district heating

- air-cooled condensers >1 bar

- steam pressure reducing stations

- switchboards

These additions to the Spilling product line are of course always adapted to suit the requirements of your application. Combined with the comprehensive Spilling know-how of integrating steam turbines in whole systems, the interfaces for Spilling customers can be kept to a minimum. Spilling supplies a corresponding engineering package to integrate the unit into the existing system.

Customer reviews

No reviews were found for Spilling - Steam Turbine. Be the first to review!