Spire Metering - Model ThermoPro Series TP10 - Non-Intrusive Clamp-On Ultrasonic BTU, Thermal Energy Meter

From Wall Mount Ultrasonic Flowmeters

The TP10 ultrasonic thermal energy meter provides abundant capabilities for accurate thermal energy measurement of a liquid-based thermal energy production / transferring system. It is the 3rd generation energy meter from Spire Metering Technology. Compared to its predecessors, the 3rd generation offers better performance and a richer feature set, all at a lower price.

Product Details

The TP10 system is consisted of a high performance ultrasonic flowmeter EF10 and a pair of standard PT100 temperature sensors. The ultrasonic flowmeter is based on our cutting-edge clamp-on flow measurement technology, which is capable of measuring the flow from outside of a pipe accurately and reliably. Due to the non-intrusive nature of this technology, there is no pipe cutting, no moving parts, no pressure drop, no leaks and no risk of contamination. Besides, the installation is simple and requires no special skills or tools.

The two PT100 sensors, which could be either insertion type or surface-mounting type, are used to measure the temperature of the supply flow and the return flow. The energy consumption rate is then calculated based on the temperature difference and the measured flowrate. A built-in energy totalizer is used to accumulate the amount of energy delivered.

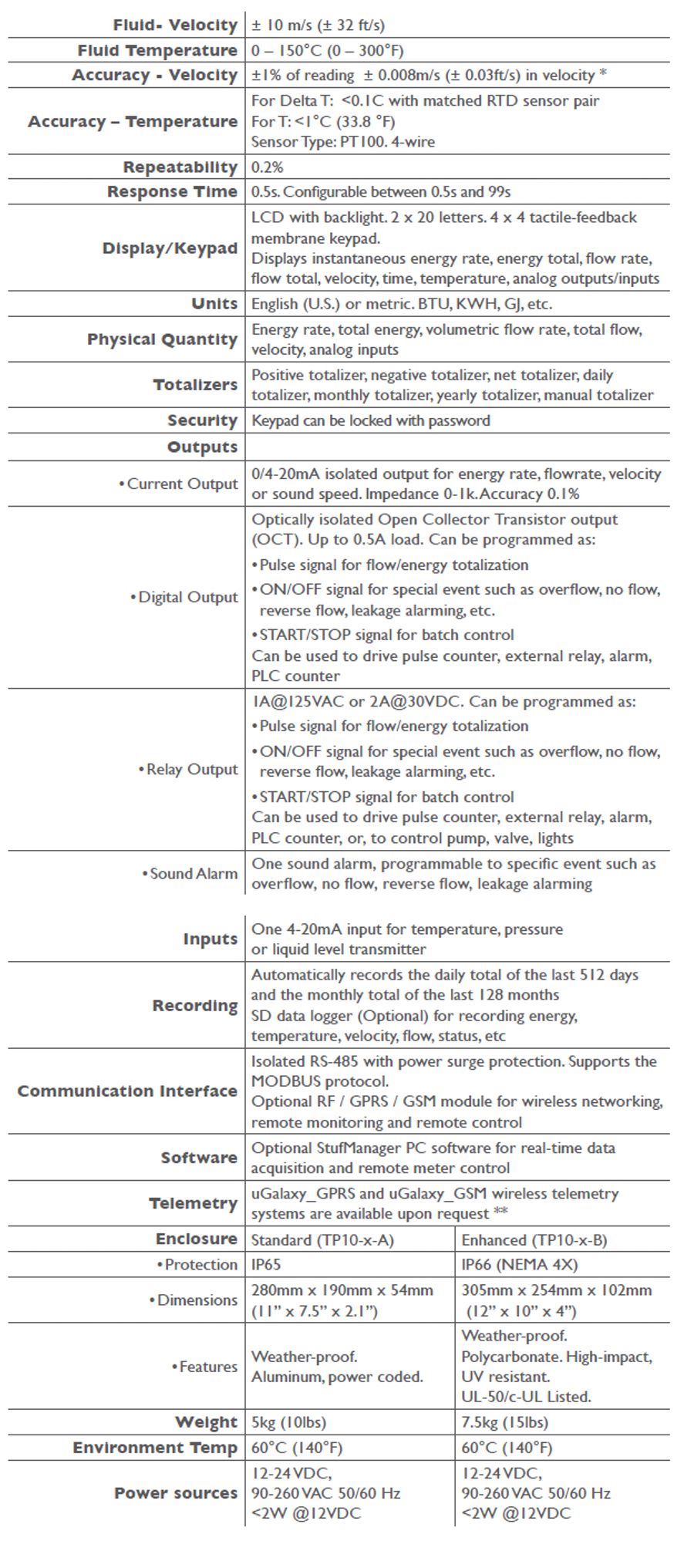

TP10 provides versatile input/output interfaces, such as isolated digital outputs, relay output, batch control, alarm, 4-20mA output. In addition, the built-in isolated RS-485 port with surge protection and MODBUS support makes remote energy monitoring and energy meter networking easy and reliable. Other output modules, such as BACnet module, Ethernet module, GSM/GPRS wireless module, RF module and more, can be added to the standard package.

TP10 is an ideal choice for improving HVAC, energy production and building energy efficiency in terms of heating, cooling ventilation and air-conditioning.

Best Practices TP10

Application

A major pharmaceutical company with a large facility in the greater Philadelphia area consumes as much as 300 million BTU s of thermal energy per day to cool their labs, equipment, offices, and other facilities. The chiller distribution network runs across several buildings over long distance and throughout underground tunnels. The pipe sizes at this facility range from a few inches up to 24 inches. The chiller system is managed by a facility management company. In order for the facility management company to bill their client properly, it was necessary to install an energy metering system to accurately measure the energy consumption of each compound. In addition, due to the long pipe lines, it was crucial to know if leakage of water or energy occurred on a real-time basis.

Problem

This application presented major challenges for traditional BTU meters, such as turbine-, orifice- or even electromagnetic- based BTU meters. The end customer did not want to stop the flow and energy supply. It also prohibited the drilling of holes on the pipe or cutting of the pipe. In addition as the water may not be clean after many years of operation, any meter with moving parts could be problematic.

Another challenge was the large 24 pipe size. An insertion flowmeter would not be accurate due to a limitation in the sampling area; i.e., the energy is not uniform along the entire pipe cross-section. Also, an inline type flowmeter was too costly to consider.Energy leakage was another issue to consider due to the large amount of thermal energy transported throughout this network. Any bad insulation could cause a large monetary loss without warning.

Solution

Spire Metering specializes in energy and flow monitoring. Its TP10 ultrasonic thermal energy meter is a non-intrusive and robust instrument which accurately measures flow, temperature and thermal energy consumption (BTU). The transducer can easily be clamped onto any pipe size without cutting the pipe or shutting down the flow. The TP10 does not have any moving parts to wear and tear, thus, saving in maintenance costs. Most important, the cost of the TP10 does not increase due to pipe size, as it utilizes the same transducers for both small and large pipes. The TP10 uses cutting-edge transit-time technology and patented digital signal processing algorithm. It is able to conduct flow and energy measurement with excellent precision. This allows it to detect small flow and energy consumption, which is critical for locating leakage in a complicated pipeline network. Therefore, a number of TP10 units can be installed on the chiller distribution pipelines. All of the TP10s communicate with the BMS system for data collection and data analysis.

Results

The entire thermal energy measurement system has been up and running for approximately 40 days as this application note is written. The following two figures illustrate the excellent performance of the TP10 energy meters.

As indicated below, the blue curve represents the energy rate histogram of the meter on the 24 pipe (the main pipe); the additional three curves represent the energy rate histograms of the meters on three branch pipes, 18 , 12 and 4. The energy rate in this graph is in million BTU per hour. Based upon the information, it is quite clear that the energy variation pattern of the branch pipes follow that of the main pipe. This clearly indicates that all the TP10 energy meters within the system are providing consistent results.

The data for the 4 pipe is very small in comparison with the other noted pipes. The energy pattern on this pipe is not as obvious which may be due in part to the nature of the energy consumption pattern of that particular building. In addition there are still several pipes within this facility which are not yet in service, therefore the data is not available.

Advantages

- Non-intrusive thermal energy/BTU measurement

- Easy and economical installation; no pipe work required

- No moving parts to wear and tear; no maintenance required

- Industrial grade temperature sensors and ultrasonic sensors for improved robustness

- Paired PT100 RTD sensors and ultrasonic transducers for improved accuracy

- Suitable for pure liquids and liquids with some particles; no dependency on conductivity

- Suitable for all commonly used pipes

- Bi-directional flowmeasurement

- Seamless integration of temperature and flow so as to deliver a complete energy metering solution

- High-performance; abundant input/output features, such as 4-20mA, relay, alarm, task scheduler, batch controller and more

- Totalizers for flow, energy, daily energy and monthly energy

- Large data logger for recording multiple variables (optional)

- Communication: RS485/MODBUS. Optional GPRS, GSM, RF wireless

- Compatible with the uGalaxy telemetry system for centralized energy distribution management

Conclusions

The clamp-on ultrasonic energy meter has been successful in a large pharmaceutical facility to monitor the thermal energy distribution system. The observation of 40 days of data demonstrates the impressive performance of Spire Metering's TP10 energy meter. It provides the facility manager with confidence that their distribution system is in excellent health.

The entire installation and system tuning was completed within two days time, therefore a quick andeconomical installation. This is only possible with non-intrusive clamp-on ultrasonic technology. The fact that the size of the pipe was as large as 24 , one can only imagine how expensive and labor intensive it would have been to use another type of technology, i.e., mechanical flowmeter or magnetic flowmeter. TP10 BTU meter resulted with saving the customer major installation costs and quickly delivered most favorable results.

In summary, the benefits of the Spire Metering TP10 energy metering system include:

- Non-intrusive installation thereby significantly saving money and time, in particular for large size pipes

- No moving parts, thus, almost no maintenance, thereby savingmaintenance costs

- Accurate flow and BTU measurement improves chiller plant control

- Real-time data and balancing information to improve system efficiency

- Continuous monitoring of flow, temperature, and energy transportation guarantees system performance along with providing alarm for potential risk or energy leakage

Features and Benefits

- Energy rate and total consumption measurement

- Unique 2 years warranty

- Non-intrusive clamp-on technology. Easy and economical installation

- No moving parts to worn out. Long-life span. No maintenance

- High accuracy. Thermal energy custody transfer performance

- Wide flow measurement range, bi-directional

- Built-in totalizers, batch controllers and task scheduler

- Isolated RS-485 interface. Supports MODBUS protocol

- Abundant inputs/outputs, such as 4-20mA output, relay output, pulse output, alarm output, etc.

- Easy to use and set up. Self-explanatory menu-driven programming

- NEMA 4X (IP65) Weather-resistant enclosure Low-power consumption, less than 1.5Watts

- Suitable for virtually any liquid heating/cooling systems such as HVAC, office buildings, apartment complexes, condominiums, solar heating systems and geothermal systems

Applications

- Chilled water sub-metering

- Hot water sub-metering

- Condensate and heating water circuits

- Boiler feed water

- Glycol / Water mixture

- Thermal storage

- Geothermal system

- Solar hot-water system

- Chemical feed / Ammonia feed

- Power plants

- District energy management and billing

- LEED / Green building verification, green credit applications

- Energy consulting

- Facility management in shopping malls, campuses,

- industrial parks, hospitals, commercial buildings,

- government buildings, airports and more

Customer reviews

No reviews were found for Spire Metering - Model ThermoPro Series TP10 - Non-Intrusive Clamp-On Ultrasonic BTU, Thermal Energy Meter. Be the first to review!