THIOPAQ - Oil & Gas Desulphurisation Technology

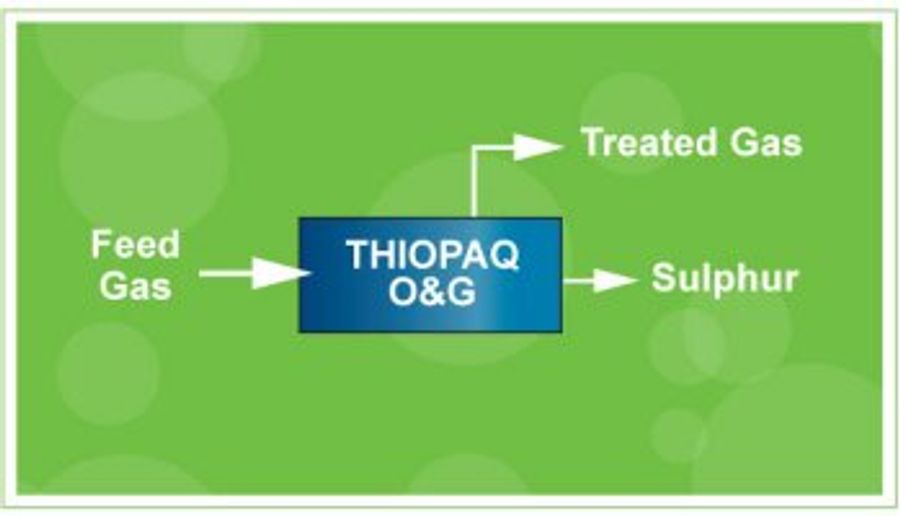

Gas Desulphurisation is notoriously difficult for small to medium sized sulphur sources and for ‘lean’ acid gases in particular. Most other solutions result in either high operational cost or in laborious operations. Or both… With THIOPAQ O&G, Paqell offers a way out. The THIOPAQ O&G process integrates gas desulphurization with sulphur recovery in a single unit. That means you can use feedgas straight from the source or offgas from an amine unit. THIOPAQ O&G can be applied to low and high pressure gases.

THIOPAQ O&G Benefits

- Inherently safe operation:

- No free H2S downstream absorber

- Ambient temperatures for the whole system (solution temperatures of 25-40 °C)

- Bioreactor and sulphur recovery at atmospheric pressure

- Essentially complete H2S removal and recovery as elemental S

- Low total cost of ownership

- Always there when you need it: ˃99% availability

THIOPAQ O&G Process Description

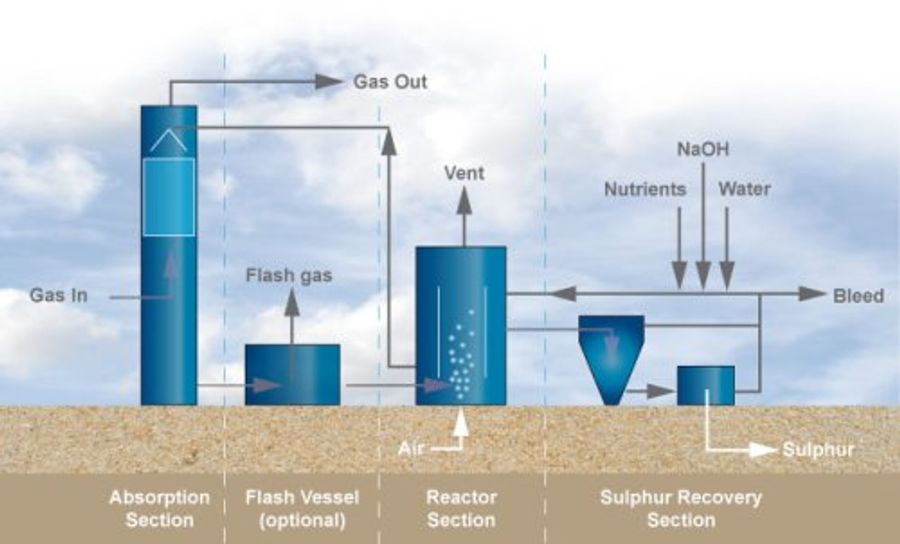

The THIOPAQ O&G process integrates gas purification with sulphur recovery in one unit. The sour gas first comes into contact with the lean solution in the absorber. This solution absorbs the H2S to form sodium sulphides, and sweet gas exits the absorber.

Depending on the sour gas pressure, the sulphide-loaded or rich solution is routed to a flash vessel or directly to the bioreactor, which is operated at atmospheric pressure and ambient temperature, and where the micro-organisms oxidise the sulphide to elemental sulphur. The lean solution is recirculated to the absorber, while part of the lean solution is routed to the sulphur recovery section, in order to remove sulphur from the system.

The produced elemental S is separated from the solvent in the sulphur recovery section. Part of the bioreactor contents are recycled over the settler to maintain the desired dry solid content in the system. The concentrated slurry is then further processed in a decanter centrifuge or a filter press. The recovered water is recycled back to the process via the bioreactor. A small slipstream of the clear solvent is bled from the system to prevent an accumulation of salts beyond the allowed maximum.

The Power of Nature

The key of the THIOPAQ O&G Process lies in the biological aspect, i.e. the regeneration of the bicarbonate solution by the activity of the bacteria, which belong to the group of naturally occurring sulphide oxidising organisms such as Thiobacilli. These are autotrophic organisms, which means that CO2 is required as their sole carbon source. The organisms are naturally occurring and are not genetically manipulated or modified.

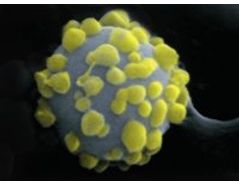

The bacteria population is harmless to the environment, fast-growing and highly resistant to varying process conditions. The energy needed for growth is obtained from the sulphide oxidation process. The photo on the right shows the main body of a bacterium with lumps of elemental sulphur as these are excreted from the body.

The bacteria have proven to be extremely robust in the face of a variety of challenges, which is demonstrated by the fact that not a single application has required a colony replacement since the first unit started up in 1993.

Gas Processing Options

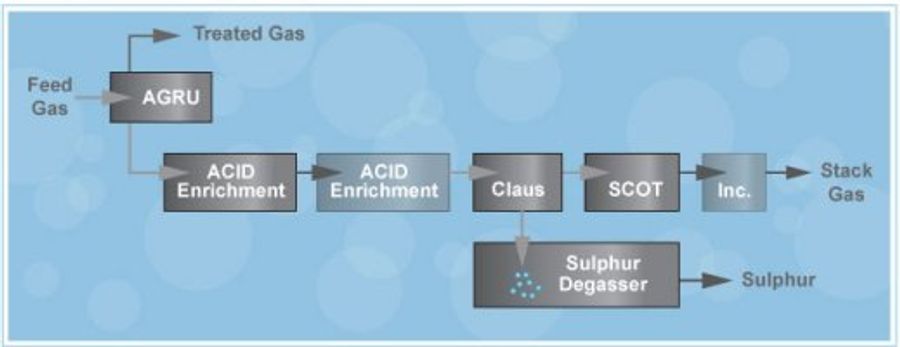

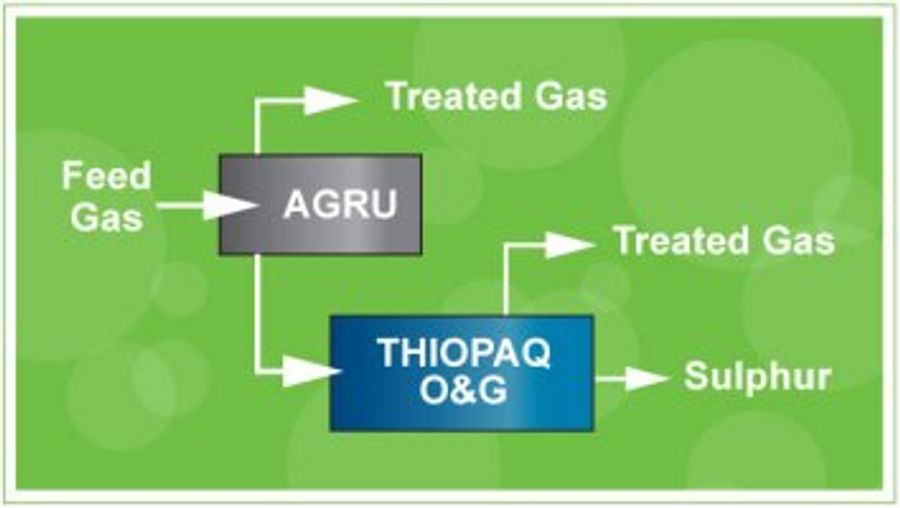

The THIOPAQ O&G process can replace a complete train of H2S removal and sulphur recovery installations. Another option is to retain the amine unit (for example, when CO2 removal is also required) and only replace the sulphur recovery unit, the tail-gas treating unit, the degasser and, possibly, the incinerator with a single THIOPAQ O&G train.

Biosulphur

Another important feature of the THIOPAQ O&G Process is the fact that the produced sulphur, also known as biosulphur, has special properties. The biosulphur does not show the hydrophobic behaviour which is typical of the chemically produced sulphur from claus and redox processes, for example. This has a very positive effect on the operation: the solution behaves like a relatively stable suspension without clogging or other nuisances.

Biosulphur based agricultural fertilizers and fungicides

Biosulphur is the basis of a range of new agricultural products designed to act as (ingredients for) liquid fertilizers and liquid fungicides. The very small size of the sulphur particles adds to the appeal since it guarantees an even distribution over the crops and easy absorption by the plants and soils it is used on.

Customer reviews

No reviews were found for THIOPAQ - Oil & Gas Desulphurisation Technology. Be the first to review!