Wind Harvest - Model H-Type - Vertical Axis Wind Turbines (VAWTs)

The first markets for 57' to 90' tall Wind Harvesters will be distributed energy projects where tall turbines can't go because of their impacts on views, acoustics, radar, and endangered species or because they won't fit on the roads, through the ports or within the setback easements. The Company is now taking orders for delivery of turbines to such projects for delivery in 2026 and 2027. The largest installations of utility-scale VAWTs will be the understories of new and existing wind farms. Research from CalTech, Stanford and other universities predicts that VAWTs will draw down faster moving wind into the rotors of the HAWTs and can increase the tall turbines energy output by 10%.

Product Details

Wind Harvest was granted five patents in 2024 with four pending and expected to be granted in 2025. The Company won a 2024 Patents for Humanity award from the US Patent and Trademark Office. These patented innovations (e.g hinge connections between the blade and arm) will likely be needed by future competitors who also want to make 25-250kW VAWTs that can handle turbulent wind and rotate 10M and 20M times per year.

The first market will be distributed energy projects where tall turbines aren’t permitted. Our turbines’ largest market will be new and existing wind farms.sturdy, long-lasting machines are a key missing technology urgently needed to meet critical local and national renewable energy goals.

Our wind turbines will be first to market to take advantage of the middle layers of wind (from 15 – 100 feet above the ground).

Wind Harvesters should be fully certified and ready for sales in the second half of 2026.

Technical Data

- Warranty - Five years. Extended warranty - ten years

- Tower Options: Lattice, Wood or Steel Monopole

- Generator options:Th 70kW, 60kW and 50kW

Note. The 4.S (special) version of the Wind Harvester has larger foundations and stronger anchoring system with other minor changes so that it can survive 180mph gusts that accompany Category 5 hurricanes and typhoons.

Commercial Product

We’ve learned a great deal through the process of designing and prototyping full-scale H-type turbines. Model 4.0 is the culmination of our efforts and the product we will bring through the certification process and into the market.

Its highlights include:- More aerodynamic and efficient design

- Easier-to-make, install and maintain

- More durable and longer lasting

- High energy density with 6 megawatts installed per linear mile of road and 133 megawatts installed per square mile of land.

Pilot Project

A significant amount of research and development, prototyping, and modeling have gone into our Wind Harvester™ turbine technology. We completed Technology Readiness Level 7, a pilot project operating in industry (gusty) conditions with our Model 3.1t the UL Advanced Wind Turbine Testing Facility in Texas. We redesigned the turbine into the Model 4.0 with patented innovations that lower fabrication, assembly and installation costs and increase the energy output of the turbine. It is ready for TRL 8 - third party 'small wind' certification to IEC 61400-2 standards.

Compact Size

With blade tips reaching 55-100 ft above the ground, Wind Harvesters are approximately 20% the height of traditional commercial-scale turbines. Tightly spaced “arrays” of our H-type turbines easily fit under and around tall turbines and in places where the larger machines can’t go.

Rugged and Durable Technology

Traditional, propeller-type turbines have blades that attach to horizontal drive shafts at a single point. Wind Harvesters have vertically aligned drive shafts with two supporting connections per blade. This configuration allows Wind Harvesters to overcome the shaking problem traditional turbines have in turbulent wind conditions.

Our 99% galvanized steel and aircraft aluminum turbines can endure harsh conditions for 40+ years with regular maintenance and replacement of critical parts.

Capturing Energy Between Two Ridges

Wind Harvesters can capture the turbulent wind that flows nearer to the ground between ridges. Traditional turbines capture the laminar flow that runs higher above ground.

Synergy through the Coupled Vortex Effect

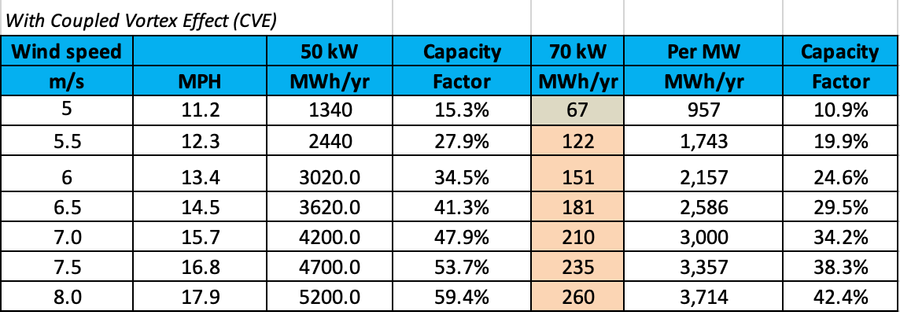

When arranged a few feet apart from one another, a pair of H-type wind turbines creates a synergistic effect that increases wind speeds through their own and their neighbors’ rotors to enhance aerodynamic efficiency. The increase in efficiency creates a 10-20% increase in energy output. This physical phenomenon, discovered, proved, and patented by Wind Harvest co-founder, Bob Thomas, is called the Coupled Vortex Effect.

The energy produced by Wind Harvesters in different average annual wind speeds is shown in the table below as well as in the power performance curve which compares the power performance of Wind Harvester Models 3.1, 4.0 alone and and 4.0 with the coupled vortex effect.

Advanced Computer Modeling

With over 40 years of wind turbine experience, Led by renowned scientist and engineer Dr. David Malcolm’, our engineering team used the information gathered from past Wind Harvester prototypes to confirm the accuracy of a suite of computer model data. This validation was a technological breakthrough for Wind Harvest, H-type VAWTs, and renewable energy.

Patents

Wind Harvest has numerous patents it will be filing before the public sees the Model 4.0 turbines. These patents are designed to make future competitors want to license our intellectual property to more cost effectively make their own mid-level wind turbines and make sales into the massive mid-level wind markets that Wind Harvest will open.

New Turbines for Massive Untapped Wind Resources

Mid-level wind harvesting represents a huge opportunity to bring more clean energy to the fight to restore our climate. Our Wind Harvesters will be the first modern turbines to capitalize on this unused resource, 15 ft to 100 ft (5-30m) above the ground.

When placed on existing wind farms, Wind Harvesters can double the land’s energy output with minimal environmental impacts. One hundred forty gigawatts of power—enough energy to supply 120 million households around the world with electricity—could be readily available by simply adding Wind Harvesters to the best 20% of existing wind farms. That is a vast, easy-to-tap market with zoning and key infrastructure already in place.

Besides using turbulent mid-level wind under tall turbines there are many windy properties worldwide where traditional turbines cannot go, but ours can.

Wind Harvest has an unprecedented opportunity to bring exponential growth in wind power production to the clean energy boom. Join us! Together, we can keep the world from blowing past the climate change tipping point.

The Potential

Introducing Wind Harvesters

Wind Harvesters are compact H-type vertical axis wind turbines that generate power from highly energetic and turbulent middle layers of wind that traditional turbines can’t use. Placed three feet apart from each other in arrays with closely spaced rows, they have the highest energy density of any renewable energy technology available.

Augmenting Wind Farms

Wind Harvesters can double the energy output of existing wind farms while improving grid reliability. They operate under and around traditional turbines and can increase the energy production of each.

Distributed Energy Production

Groups of compact Wind Harvesters, often in conjunction with solar and storage, can reliably supply inexpensive power to our homes and businesses via the distributed grid from windy properties that cannot fit in or secure permits for tall turbines.

Customer reviews

No reviews were found for Wind Harvest - Model H-Type - Vertical Axis Wind Turbines (VAWTs). Be the first to review!