Zuccato Energia - Model ZE-400-LT - 420-KWE, Skid-Mounted, Low Temperature Organic Rankine Cycle (LT-ORC) Power Generation Module

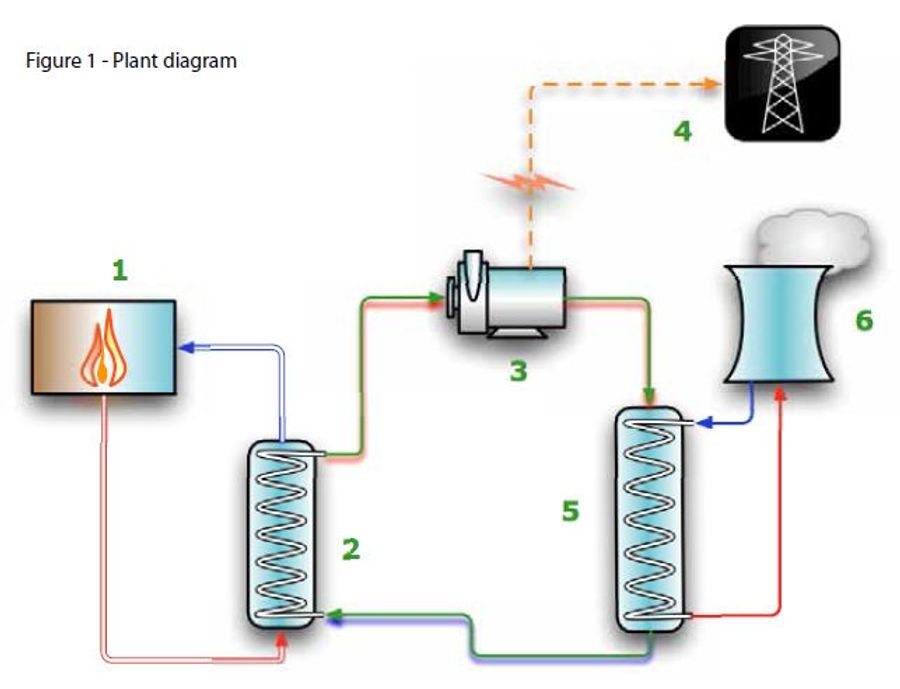

The structure of the proposed plant is based on the so-called low-temperature organic Rankine cycle (LT-ORC), and may be summed up by the diagram in Figure 1. A heat source [1] generates heat, which is conveyed through a vector fluid circulating into a closed loop to one or more primary heat exchangers, usually a preheater and an evaporator [2], where said heat is transferred from the vector fluid to the working fluid.

The working fluid - a low-boiling, biodegradable, ...

The working fluid - a low-boiling, biodegradable, non toxic liquid when at room temperature - boils in the evaporator at a temperature far lower than that of water, becoming a high-pressure dry gas which spins through its expansion the impeller of a specifically designed and sized turbine [3].

The high-speed rotation (12.000÷18.000 Rpm) of the turbine shaft spins the rotor of a generator which is directly connected to it, thus producing electric power [4] which, after being synchronized in frequency, phase and voltage by a power converter, may be injected into the national power grid or self-consumed, according to local needs and policies.

Downstream the turbine, the working fluid - still in gas phase - is conveyed to another heat exchanger, called a condenser (5), where it is cooled, releasing its excess heat and condensing back into a liquid which is collected in a condensation tank, ready to be sent back to the primary heat exchanger by a recirculation pump, thus closing the loop.

Excess heat released in the condenser is a low-temperature thermal energy source itself, which may be used for other purposes such as preheating or dessiccating biomass fuel (thus increasing its heating value), building heating, hot water production and so on.

In case that is not possible, residual heat may be dissipated by using an external cooling system [6] such as an evaporative cooling tower or a dry cooler.

High Power, High Efficiency

The ZE-400-LT is one of the largest power generation modules offered by Zuccato Energia, designed to operate in conjunction with boilers in power generation applications but equally well suitable for industrial heat recovery systems where large enough quantities of mediumtemperature (≥160°C) waste heat are available. If required, this modular unit is also capable to be coupled with other similar or smaller units to take advantage of all available thermal power.

The use of shell-and tube heat exchangers for the cold side instead of the usual brazed plate units gives the system the highest efficiency (16%) of all the Zuccato Energia range of products.

High-Performance

Independently designed and manufactured using the most advanced technologies in finite elements and fluid-dynamics analysis (CFD/CFX), ZE turbogenerators are designed from scratch to operate in a low-temperature organic Rankine cycle which uses a special working fluid that offers better performances and several advances over traditional steam turbines:

- Low operational temperature which allow our systems to tap even low-grade heat sources;

- High condensation temperature which may allow the use of simple air-cooled condensers;

- Totally dry working fluid, which means no turbine blade erosion, giving the system high reliability and reduced maintenance costs as well as fewer controls;

- Lower operational pressures (20 bar max), which mean safer operation, less bureaucratic prodlems and reduced plant costs;

- No atmospheric emissions (closed circuit operation);

Environment- Friendly

From an environmental standpoint, ZE systems are reproachless:

- They recover otherwise wasted resources such as waste heat and byproducts or help tapping renewable sources such as solar and geothermal heat;

- They use plain tap water for thermal energy transfer instead of environmentallydangerous diathermal oil;

- Their working fluid is ozone-friendly, non-toxic, non flammable in liquid form, and 100% biodegradable;

- They are made of recyclable, environmental friendly materials, use a minimum of plastic parts and employ no toxic substances in their construction.

Innovative Solutions

The ZE turbogenerators have been custom designed from scratch for the purpose of being installed in small plants (less than 1MWe). So, several engineering solutions have been incorporated in their design to enhance their performance:

- Direct turbine-to-alternator coupling, to eliminate the attrition losses inherent in gearboxes;

- Use of ceramic bearings to prolong operational life and allow very high-rpm operation;

- Custom-designed and sized turbines and power converters for every plant size to obtain optimal mechanical-to electric energy conversion and performance in energy grid output.

Our innovative technology has already been widely field-tested with success in dozens of plants throughout Europe, Asia, Africa and America, from biomass and biogas fueled plants in Italy to solar-assisted plants in Africa, from large farms in the USA to Korean power stations..

All systems by Zuccato Energia are equipped with telecontrol and telediagnostic systems that allow constant monitoring and real-time intervention in case of malfunction through the 3G / GPRS / EDGE cellphone network and any Web-savvy device (PC or tablet).

ORC Circuit Components

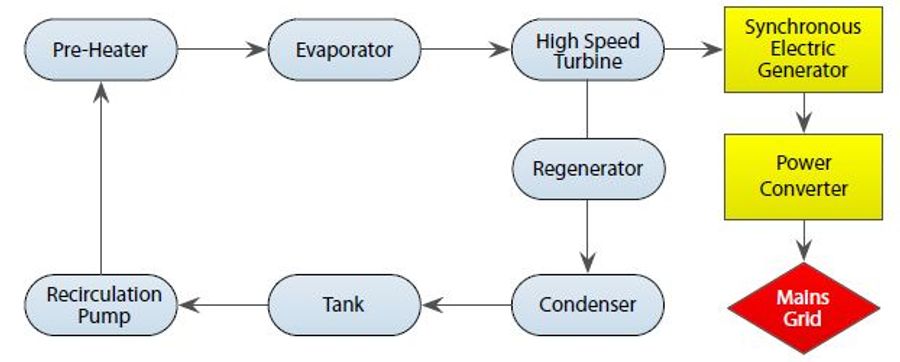

Besides the aforementioned working fluid, the power generation module is made of various elements, shown in the following diagram.

Pre-Heater: in this heat exchanger, the heat from ...

- Pre-Heater: in this heat exchanger, the heat from the heat source, conveyed to the ORC module by the vector fluid, preheats the working fluid;

- Evaporator: in this heat exchanger, the heat of the vector fluid feeding the ORC module vaporizes the working fluid changing its state from liquid to gas, so increasing its pressure;

- Turbine: propelled by working fluid expansion, it has an ultralight impeller that reaches very high rotational speed (12-18.000 rpm) drawing along the generator rotor assembly;

- Synchronous Electric Generator: spinning at high speed thanks to its direct connection with the turbine, it produces electric power.

- Inverter: Ensures generator output meets all specifications (phase, frequency and voltage) to interface with the national power grid;

- Regenerator: pre-preheats the incoming working fluid using the heat from the working fluid itself downstream of the turbine, to increase system efficiency;

- Condenser: reduces the temperature of the working fluid gas downstream of the turbine, to make it go back to its originary liquid state;

- Storage tank to keep the condensed working fluid in liquid form;

- Recirculation pump to pump the fluid back in the ORC loop;

Process Data

These are the estimated process data for the plant:

Preheater +Evaporator

- Total thermal power input: 2 630 kWr

- Vector fluid temperature (input / output): &160°C /145°C

- Vector fluid flow rate: 40.63 kg/s

Condenser

- Thermal power dissipation: 2 186kWr

- Condenser cooling water temperature (in/out): 28°C / 38°C

- Condenser circuit flow: 52.16 kg/s

Vector Fluid

Vector fluid is the fluid that is used to convey heat from the heat source to the ORC module where its heat is used to evaporate the working fluid described in the next page.

The two fluids operate in separate loops and never mix - only heat is transferred between them.

Zuccato Energia has chosen to use plain tap water as a vector fluid instead of diathermal oil which, while maybe slightly more efficient at heat transfer, is far more dangerous to use, as it is flammable and potentially polluting if spilled.

In this plant, the vector fluid is overheated water at 160°C - i.e. water heated above the boiling point but kept liquid under pressure.

Working Fluid

The high-performance organic working fluid is the key component that allowed Zuccato Energia to create his ORC plant, thanks to its excellent technical specifications, such as:

- Wide operating temperature range that allows tapping into low-quality heat sources that were previously considered as unexploitable;

- High condensing temperature allowing the use of standard cooling towers;

- Totally dryness when in gas form , so no cavitation and no turbine blade erosion;

- Low operational pressures grant better safety, less bureaucratic problems, lower costs;

- Total ozone-friendliness, non-toxicity, 100% biodegradability and non-flammability in liquid form, so it is 100% eco-friendly and any accidental leaks are neither harmful or dangerous;

- Closed-loop operation means almost no need for refills, no steam nor water consumption and no emissions, so plants can be cheaper to operate, simpler and more compact than equivalent steam-based ones.

The fluid inside the plant undergoes several phase changes. Main process specifications are:

Working Fluid

- Type: Mixture of environment-friendly, non-toxic, non-flammable HFCs

- Operational range (temperature/pressure): 60-165°C,max.20bar

- Condensation temperature: ~33°C

- Turbine Input temperature /pressure: 145 °C/ 16,08 bar

- Condenser output pressure: 1,17 bar

- Organic vapor mass flow: ~-6kg/s(145/40°C)

Turbine, Generator and Inverter

These are the main technical specification of the ZE-400-LT module turbine, generator and inverter:

Turbine

- Type: Single-stage radial inflow turbine w/fixed nozzles, directly coupled to the generator shaft

- Operating Temperature (input/Output): 145°C/-100°C

- Stage pressure: PS 16 (tested to 24 bar)

- Materials: Machined steel (body) / Aluminium alloy ompeiiert

- Speed control: Feedback loop on the generator current output

- Seals and gaskets: Sealed labyrinth on impeller back and optionally at generator interface. Environmental seal using gaskets and O-rings

Generator

- Type: Synchronous, permanent magnet

- Power Output: 420 kWe

- Rotational Speed: 9500Rpm(9...10kRpm)

- Output voltage: 503-577VAC@500Hz

- Cooling system: Water jacket, 15KWi heat dissipation

- Cooling fluid: Water + glycol mix @ Tin<40°C 30l/min flow

- Additional cooling (optional): Working fluid injection

Inverter

- Type: 2xlGBT- mains synchronized modules

- Total output power (nominal / max): 420 kWE / 500 kWE max (2x250 kW modules)

- Output voltage /frequency: 400 V + 5%Tol. @ 50 Hz+0,5%Tol.

- Cooling: Water-cooled

- Max operational environmenta: 1 temperature: 40nC

- Braking chopper: Built-in, 200 kj on external resistor bank

System Components

Heat Exchangers

The hot-side heat exchangers used in this power generation module are of the brazed plate type - the most compact and efficient solution for several applications. They are made by brazing several quality corrugated steel plates together, taking care first to turn the fishbone-shaped corrugations on each plate 180° from the adjacent plate. Keeping in mind that the fluid-passing sections are very small, the heat exchange-to-encumbrance ratio of these exchangers is great. Among the characteristics for this type of exchanger, these are the most important ones:

- Small size : they occupy up to 10% of the space other exchanger types require, making transport easier and the plant smaller.

- Low temperature differentials: they can work with minimal temperature differences between cooling fluid and cooled fluid, thus increasing overall system efficiency;

- Low load losses: in most cases, even lower than those of a coaxial exchanger.

- Resistance to dirt and corrosion: high fluid turbulence and total use of the available surface means a drastic reduction in deposits due to material contained in the fluids. What’s more, they may be perfectly cleaned using normal detergent fluids. Corrosion problems are avoided by using specifically resistant materials in their construction.

The cold-side exchangers are instead of the time-tested shell-and-tube type, which besides having a lower cost than equivalent brazed plate components, has better performances and is easier to clean than brazed plate exchangers when dealing with potentially contaminated cooling water, a problem that hot-side components - working in a closed loop - do not have to face.

Heat Exchange

- Type: Brazed plate (evaporators & preheaters) Shell & tube (regenerator and condenser)

- Operating pressures: 30 bar (Nominal)/ 39 bar (Test)/225 bar (Burst)

- Construction materials: AISI316 S/S & 99,9% COpper (evaporator/preheater) Steel (regenerator/condenser)

- Max working temperature: 195°C

Condensation Tank

Required to keep an adequate reserve of liquid working fluid for the plant, it is made of rustproofed carbon steel with PN25 connections, has a capacity of 500 litres and is equipped with a built-in level sensor.

Working Fluid Pump

Required to make the condensed working fluid flow back into the ORC loop, its motor is of the closed short-circuited cage type with external ventilation . Energy-efficient (class I), it has IP55 protection and is certified to the EN 60034-1 standard. Equipped with class F insulation (Tmax=155°C), its hydraulic part is kept in place between the upper cap and the pump body by tie rods.

Control Panel

The control panel, hosted in an off-skid cabinet, hosts all control, supervision, automation and communication electronics for the power generation module. Equipped with a touch-screen local control panel as well as a remote control interface, it contains all process management electronics, including temperature and pressure control electronics and alarm management systems. The control panel also include a built-in cellular modem router that allows passwordprotected, policy-regulated remote access and system control through the Internet..

Inverter and Power Dump System

Two off-skid cabinet hosts the inverter circuitry that conditions the generated power, modifying its phase, frequency and voltage to exacting requirements before sending it to the mains interface panel with low-voltage protection circuitry.

Two other off-skid cabinets host the resistor banks where each inverter dumps and dissipates as heat all the power generated as the turbine spins down during emergency stops, given that - due to safety considerations - in that situation the skid is totally cut off from the mains.

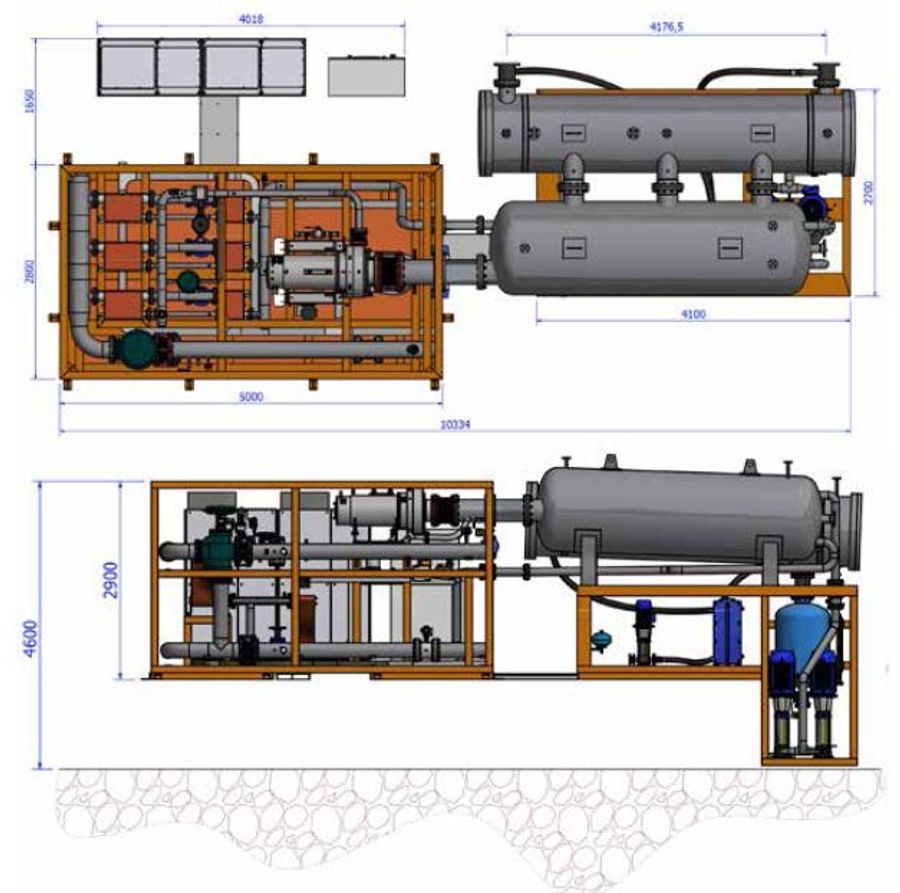

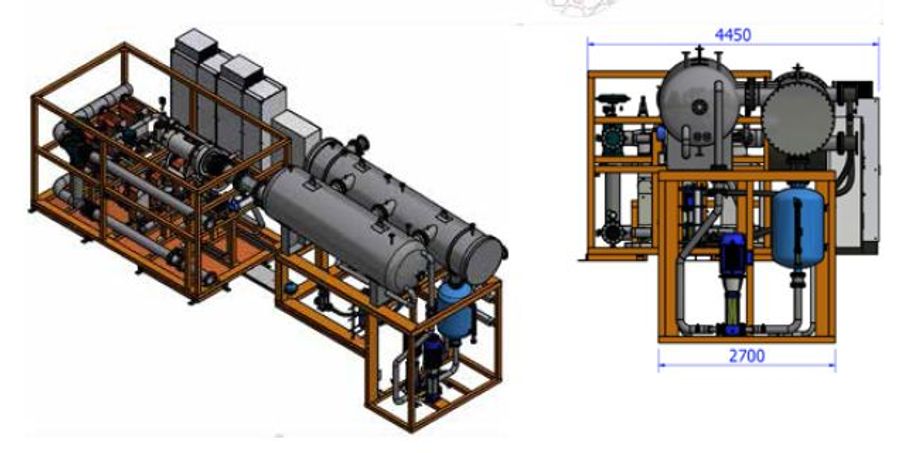

Skid Dimensions

The power generation module is supplied mounted on two interconnected self-supporting frames (“skids”), one of which houses the “hot side” components (turbine, evaporators, preheaters...) while the other houses the “cold side” - regenerator, the condenser, the working fluid tank and pump.

The following drawings show the standard, “naked” version of the ZE-400-LT ORC power generation module, which weighs about 10 tons an is designed for indoor installation.

Paneled and containerized/weatherproof versions for outdoor installation are also available.

Please note that the skid also requires at least 1...

Please note that the skid also requires at least 1.5 meters of free space on all sides for easier maintenance access.

Zuccato Energia, being the system developer and manufacturer may also build the skid in nonstandard dimensions different from the above, to tailor the system on the client’s needs.

Customer reviews

No reviews were found for Zuccato Energia - Model ZE-400-LT - 420-KWE, Skid-Mounted, Low Temperature Organic Rankine Cycle (LT-ORC) Power Generation Module. Be the first to review!