Waste-to-Energy Solutions

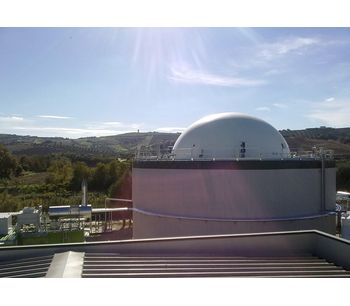

Turning waste into a resource with cost-effective and sustainable technologies. At Fluence, we have more than 30 years of experience in the design, construction, and operation of waste-to-energy plants for a wide range of industrial and municipal clients. Our proprietary anaerobic treatment technologies process wastewater and sludge to produce biogas, which can be used to produce electricity and thermal energy, or which can be purified to produce biomethane for injection into the grid.

Details

Our waste-to-energy technologies fall into three main categories:

- Anaerobic treatment of wastewater containing a high concentration of soluble COD, including wastewater from breweries, paper mills, dairies, food processing plants, and pharmaceutical companies

- Anaerobic digestion of sludge, particularly from slaughterhouses, fish processing plants, and rendering plants

- Anaerobic digestion of solid waste, including biomass, food waste, manure, agricultural waste, and silage

The main benefits of using our waste-to-energy solutions to process wastewater and sludge include:

- On-site production of energy, which can be used by the client to reduce a plant’s electricity and gas consumption

- Production of high-quality, treated effluents that meet the most stringent permitting requirements

- Reduction of sludge volume by up to 90%, significantly reducing the amount bound for landfills

- Production of a high-quality digestate that can be used by farmers as a fertilizer

- Reduction of greenhouse-gas emissions

- 100% reliability, and low operation and maintenance requirements

Every client is different, and, consequently, the biomasses they produce have different characteristics. Before designing a plant, we analyze the biomass in our laboratory to determine its capacity to produce biogas. Fluence engineers then evaluate the potential solution in business terms, calculating capital costs, operating cost reductions, and return on investment.

Market-Leading Waste-to-Energy Technologies:

Our engineers have developed some of the most efficient and cost-effective waste-to-energy technologies on the market. Here are a few of our latest innovations in waste-to-energy.

Nitrification-Denitrification:

Anaerobic digestion converts a large part of the organic carbon in biomass to biogas, but leaves the nitrogen content. In order to meet nitrogen permit limits, Fluence has developed a proprietary nitrification-denitrification process that doesn’t require the addition of an organic carbon source. The process converts the nitrogen of the digestate into gaseous nitrogen without the use of chemicals, and without generating byproducts, allowing the client to reliably meet nitrogen discharge limits.

Fluence has also developed a proprietary nitrosation–denitrosation treatment process that can be used in cases of very limited residual COD or high ammonia load. Nitrosation partially converts ammonia in gaseous nitrogen using only two thirds of the energy required by nitrification-denitrification, and is three times faster.

Biogas produced by the anaerobic treatment process can be rich in hydrogen sulfide, which is harmful to cogenerators and boilers. Hydrogen sulfide must be removed in a process called desulfurization before the biogas can be used.

Fluence engineers have developed a unique biogas desulfurization technology that doesn’t use the common methods of blowing air into the digester dome or scrubbing the biogas with a caustic soda solution. Instead, it uses a synergic process involving the wet removal of the hydrogen sulfide coupled with an auto-regenerative system of the washing solution. This significantly lowers consumption of reagents, and subsequently, operating costs. Our solution is the most cost-effective on the market.

Biogas is approximately 60% to 70% methane. Specific regulations, particularly in Europe, provide economic incentives to industries to produce biomethane for injection into the grid. Fluence works with technology partners to provide a full turnkey solution for purifying biogas into biomethane.

At Fluence, our latest anaerobic digestion innovation has focused on anaerobic MBR, a combination of anaerobic digestion and membrane bioreactor technology, which concentrates solid digestate without the use of centrifuges or dissolved air flotation (DAF). This new application:

- Can process a higher organic load than traditional technologies

- Reduces the volume required for digesters

- Provides better quality effluents

- Uses less polyelectrolyte

- Can be used to upgrade existing facilities

Customer reviews

No reviews were found for Waste-to-Energy Solutions. Be the first to review!