TabWare - Predictive Maintenance Management (PdM) Software

From Solutions

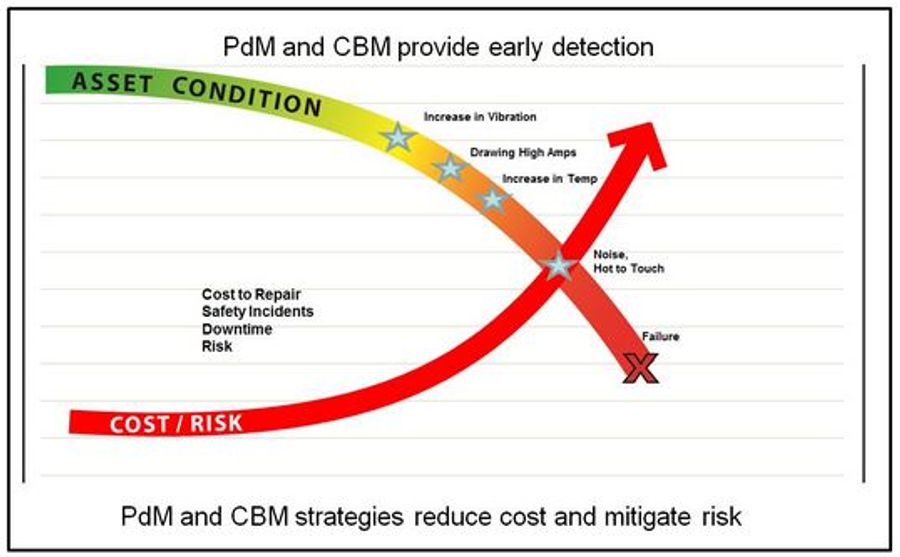

Predictive Maintenance (PdM) is a maintenance strategy that provides early detection of asset defects and conditions that lead to defects. As part of a comprehensive Reliability program, Predictive Maintenance instrumentation can tie into SCADA & Historian systems along with Energy Management and Condition-Based Monitoring. Using TabWare’s PdM/CBM interface, alarm or fault conditions trigger automatic Work Order generation utilizing preplanned standard job plans. With TabWare Preventive Maintenance and PdM best practices, organizations are more likely to avoid costly unplanned equipment shutdowns and evolve their maintenance organization to Best-in-Class status. Companies that also incorporate operational expense reduction strategies, such as Energy Management, are able to contribute significantly to their bottom line and evolve to a Best-in-Class maintenance organization.

Using the right Reliability strategy in concert wi...

Using the right Reliability strategy in concert with an effective maintenance strategy is crucial to maximize the performance of your assets. Predictive maintenance techniques such as vibration and thermal monitoring along with Reliability techniques such as Failure Modes and Effects Analysis (FMEA) and Root Cause Failure Analysis (RCFA) will result in bottom-line savings through early detection and root cause elimination.

Effective Reliability & Maintenance Strategies start with:

- A proactive approach to maintenance including early work identification, effective planning and scheduling, efficient execution of the proper plans. Planning all maintenance requirements to allocate and reserve resources and material for work orders is crucial to managing a successful proactive strategy.

- Identifying 'bad actors' through analyzing equipment maintenance data. Often a few machines account for an abnormally high percent of unplanned downtime. As a critical step of work execution, ensure that proper documentation of the equipment failure instance is completed, such as utilization of equipment class driven failure coding. Through the use of this data, an insightful analysis of history will greatly aid in determining the correct PM, PdM, and/or CBM strategy to put in place to detect or eliminate the identified Failure Modes. Oftentimes, overlooking the Failure Modes Analysis leads to inadequate PM’s or PM frequencies and results in emergency maintenance needs, high MRO emergency buys and even unnecessary work activity that can contribute to potential failures.

Customer reviews

No reviews were found for TabWare - Predictive Maintenance Management (PdM) Software. Be the first to review!